System and method for continuously loading and unloading with metering

A vacuum feeder and material storage technology, which is applied in the direction of weighing, measuring devices, automatic feeding/discharging weighing equipment, etc., can solve the problem that the weighing module cannot read data accurately, cannot meet the requirements of enterprises, and reduce Work efficiency and other issues to achieve the effect of avoiding harm to the human body, ensuring product quality, improving production efficiency and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

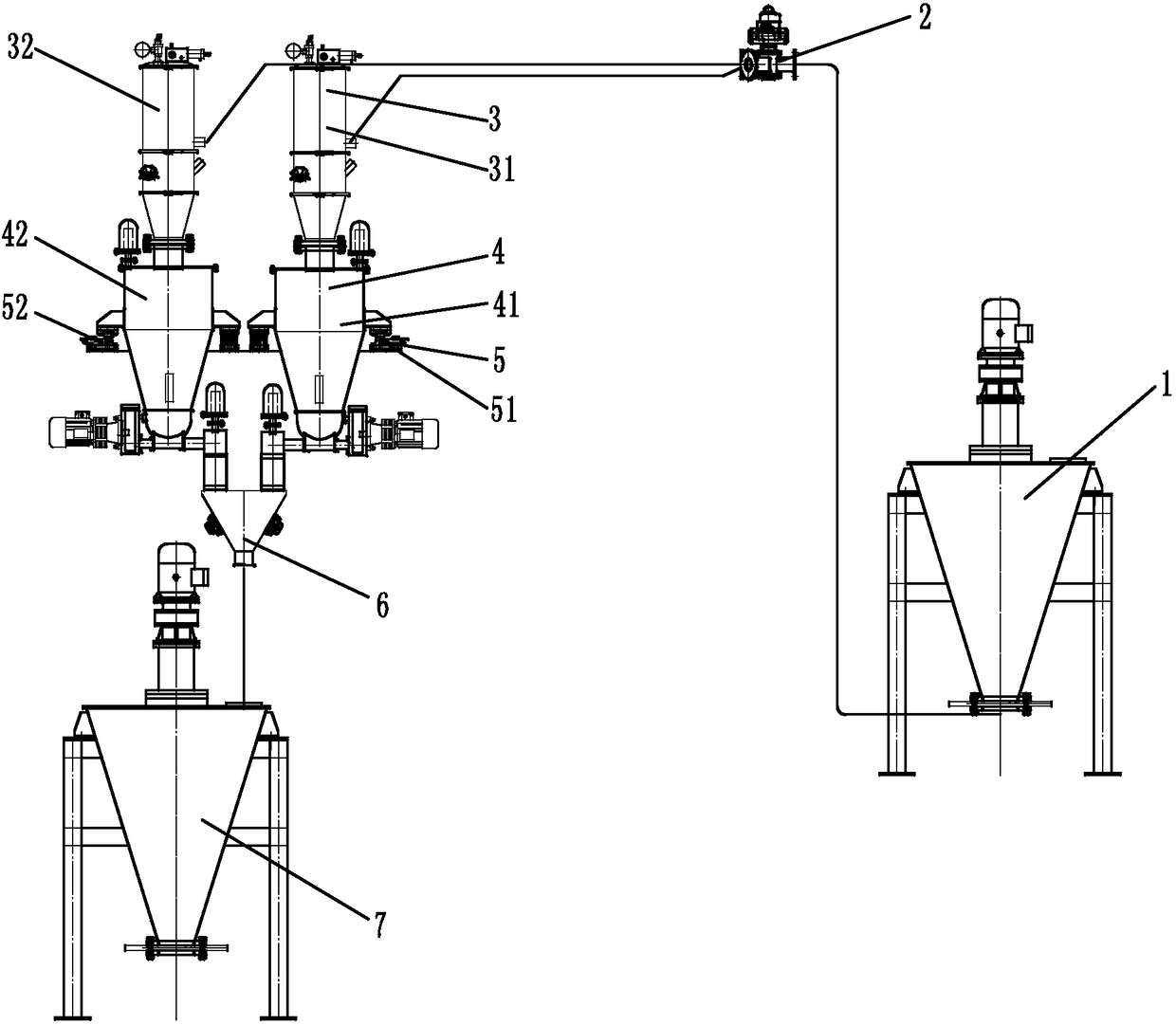

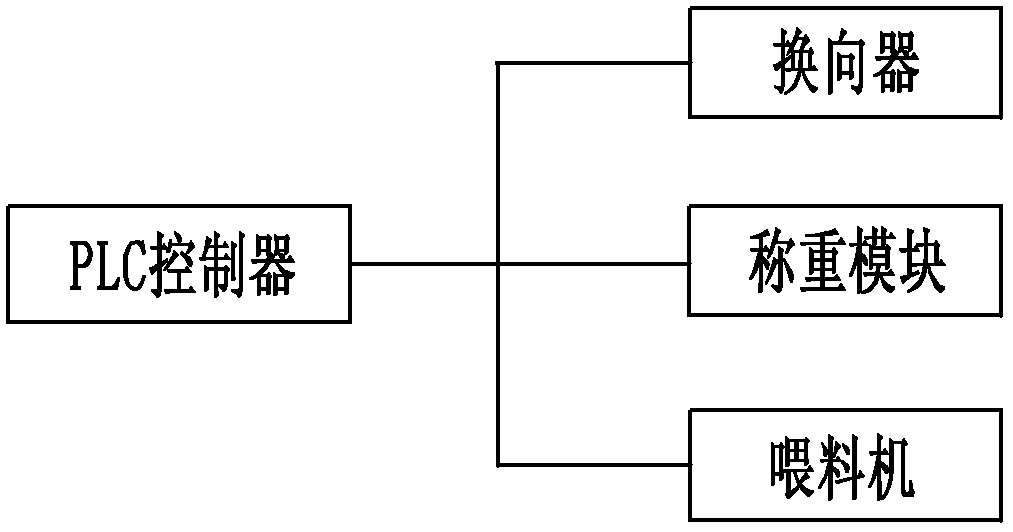

[0023] Embodiment 1: a kind of belt metering continuous loading and unloading system, such as Figure 1-Figure 2 As shown, it includes a storage device 1, a mixer 7, a PLC controller, and two sets of loading and unloading components, that is, the first set of loading and unloading components and the second set of loading and unloading components. The first set of loading and unloading components includes vacuum feeding Machine Ⅰ31, twin-screw feeder Ⅰ41 and weighing module Ⅰ51 for weighing the amount of material in the twin-screw feeder Ⅰ41 and feeding the weight information to the PLC controller. The weighing module Ⅰ51 is installed in the twin-screw feeder On Ⅰ41, the outlet of vacuum feeder I31 is connected and communicated with the inlet of twin-screw feeder I41, the outlet of twin-screw feeder I41 is connected with the inlet of mixer 7, and the feed of vacuum feeder I31 The port communicates with the material storage device 1 through the commutator 2; the second group of ...

Embodiment 2

[0030] Embodiment 2: a kind of belt metering continuous loading and unloading method, adopts the belt metering continuous loading and unloading system described in embodiment 1, comprises the following steps:

[0031] (1) Set the rated feeding volume of the feeding machine in each group of loading and unloading components in the PLC controller.

[0032] (2) The PLC controller controls the commutator to open one of the channels to connect the storage device with the first group of loading and unloading components, and the material in the storage device is added to the twin-screw feeder I through the vacuum feeder I, The feeding amount in the twin-screw feeder Ⅰ is weighed through the weighing module Ⅰ; when the feeding amount of the twin-screw feeding machine Ⅰ reaches the rated feeding amount, the weighing module Ⅰ will feed back the information to the PLC controller, The PLC controller controls the commutator to switch to close the original channel, and opens another channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com