Test device for automatic chemical reactor shutdown system and test method thereof

A technology of automatic chemical shutdown system, which is applied in the field of test equipment of automatic chemical shutdown system, can solve the problem of no emergency shutdown of the reactor, and achieve an effective and feasible solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

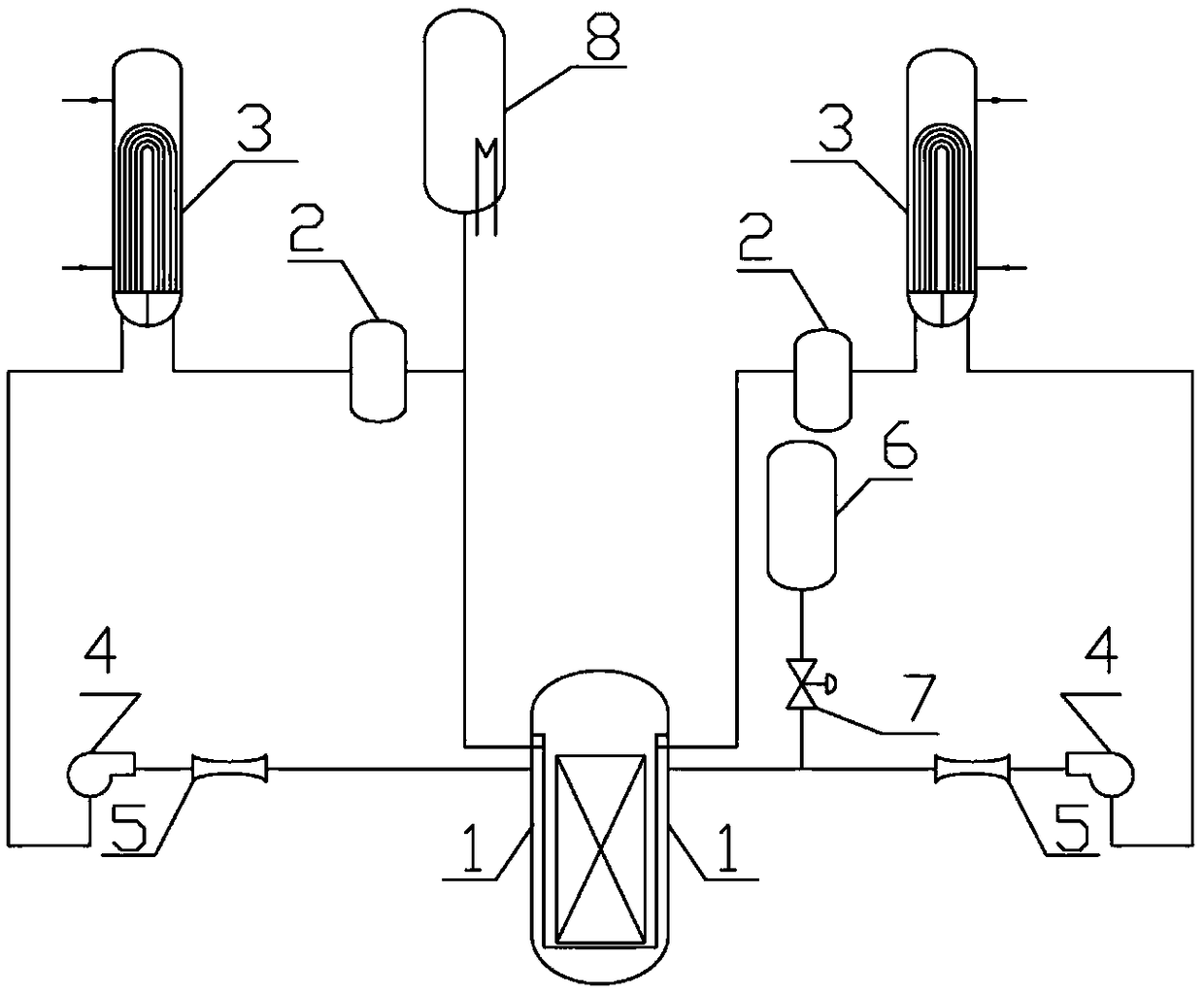

[0033] A test device for an automatic chemical shutdown system, comprising a reactor pressure vessel 1, a primary circuit system connected to the inlet and outlet of the reactor pressure vessel 1 to form a circulation loop, a pressure gauge and a thermometer arranged on the inlet and outlet of the reactor pressure vessel 1, and setting The passive automatic chemical shutdown system that needs to be tested on the primary circuit system, and the voltage stabilizer 8.

[0034] The concrete setting of the structure of the present embodiment is as follows:

[0035] The primary loop system includes a boric acid elimination device 2, a steam generator 3, a main coolant pump 4 and a flow meter 5 connected in sequence; the flow meter 5 is communicated with the inlet of the reactor pressure vessel 1, and the boric acid elimination device 2 is connected with the reactor The outlet of the pressure vessel 1 communicates.

[0036] Two groups of four connecting pipes for the inlet and outle...

Embodiment 2

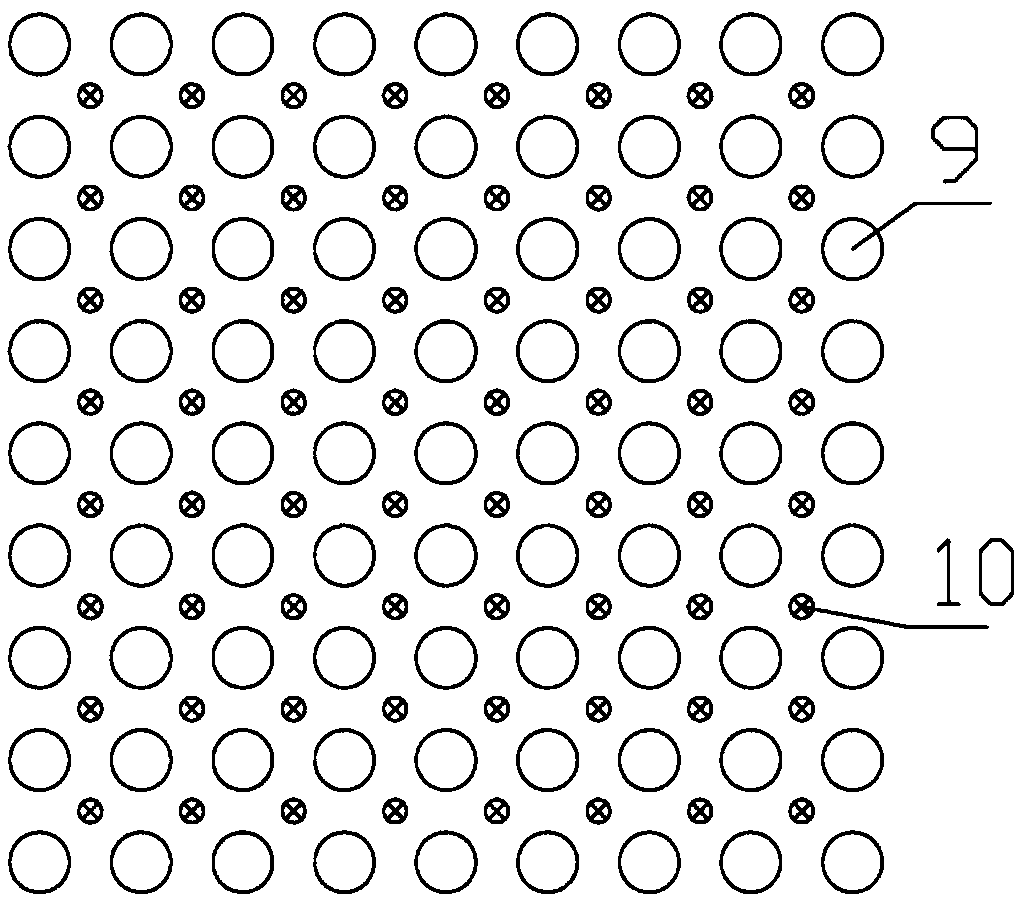

[0051] In this embodiment, on the basis of Embodiment 1, the arrangement mode of the concentrated boron detector 10 in the reactor pressure vessel 1 is further optimized, as figure 2 As shown, the specific settings are as follows:

[0052] A boric acid detector 10 is arranged between the electric heating element rods 9; the heating power of the electric heating element rod 9 is controlled by a heating element control system, and the boric acid detector 10 is connected with the heating element control system. The passive boron injection box 6 injects boric acid into the primary loop system, and the boric acid detector 10 in the core performs real-time and accurate measurement of the concentration of boric acid entering each channel in the core, and the measurement results are fed back to the heating element control system, Adjust the heating power of each electric heating element rod 9 according to the measurement and calculation results.

[0053] In this embodiment, a plural...

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the flow meter 5 in this embodiment is preferably a Venturi flow meter, a V-cone flow meter, an orifice flow meter, a mass flow meter or an ultrasonic flow meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com