Glass articles comprising light extraction features and methods for making the same

A technology for glass products and light extraction, used in manufacturing tools, optics, light guides, etc., to reduce development costs, low color shift, and prolong downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

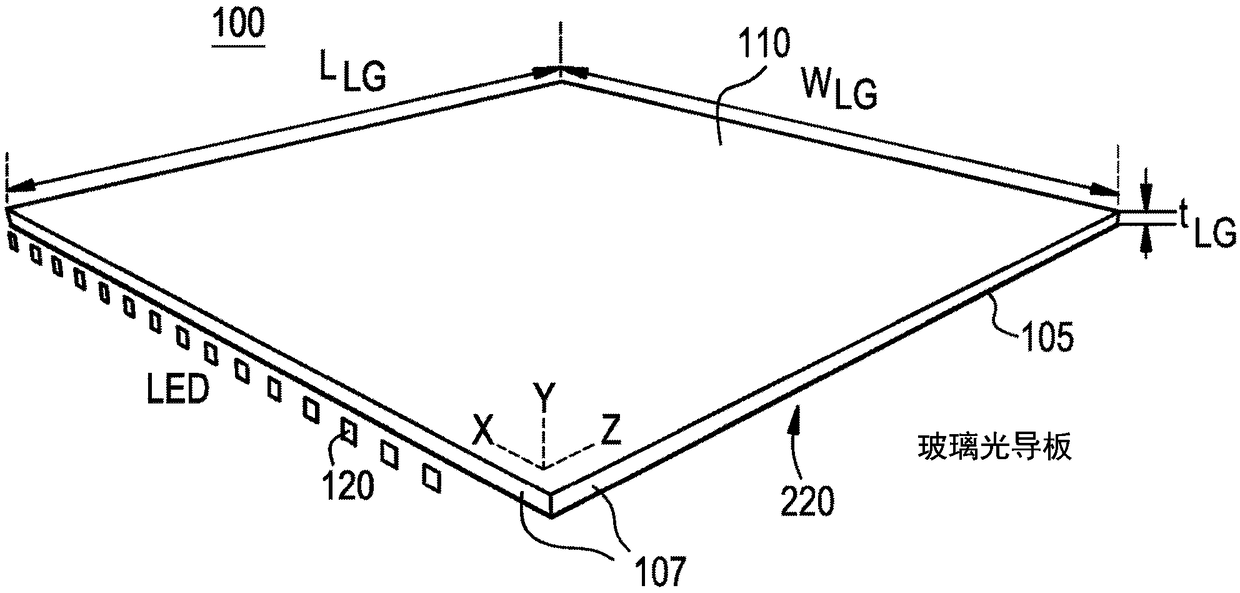

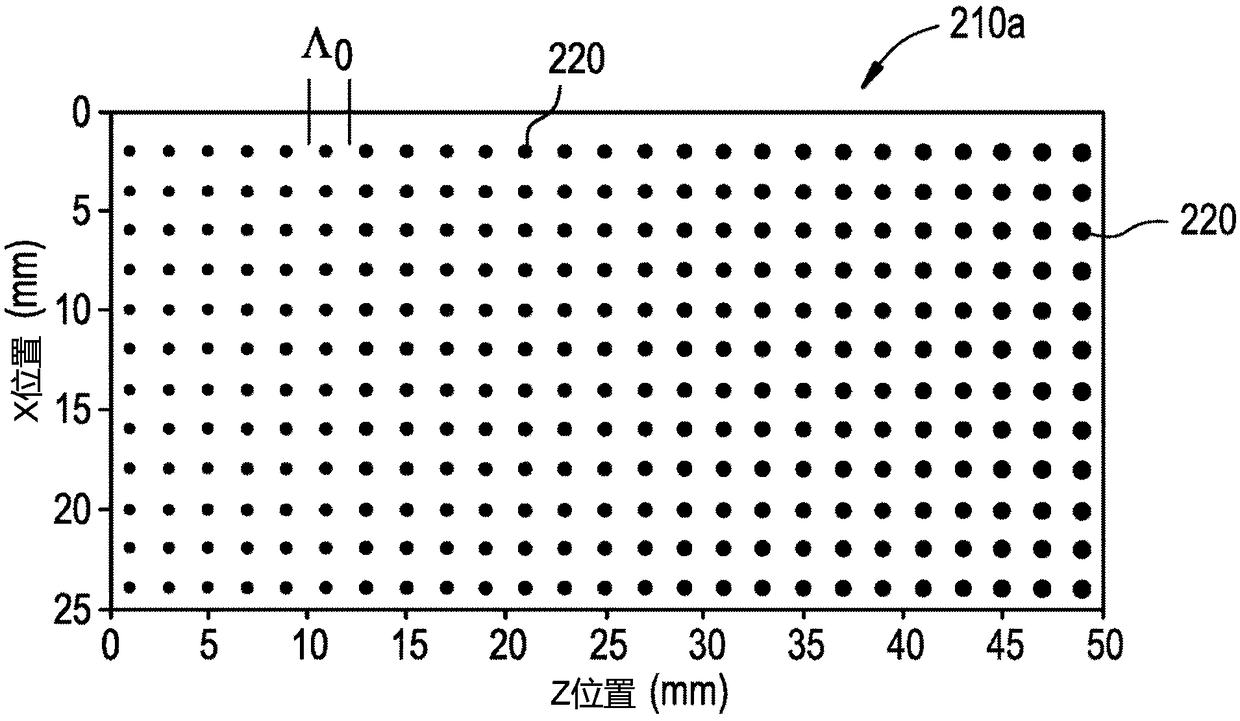

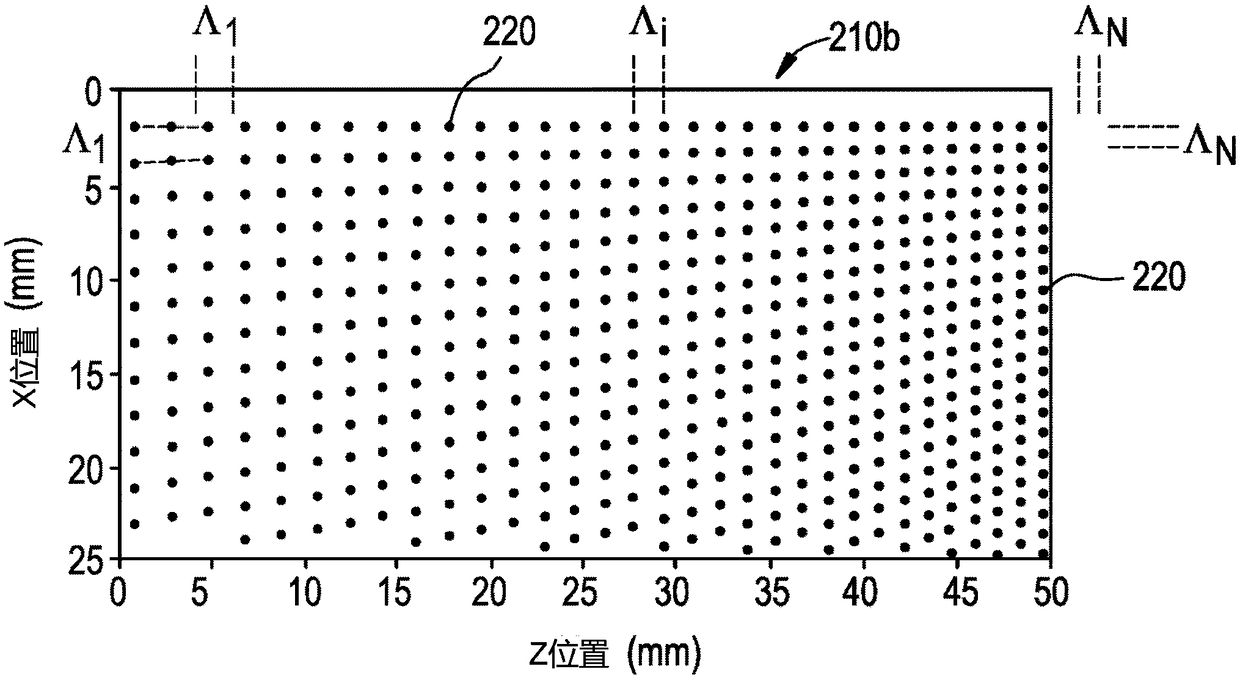

[0034] Glass product

[0035] Disclosed herein is a glass article comprising a first surface and an opposing second surface, wherein the first surface comprises a plurality of light extraction features. Exemplary glass articles may include, but are not limited to, glass light guide plates. Display devices comprising the glass articles are also disclosed herein.

[0036] The glass article or light guide plate may comprise any material known in the art for use in displays and other similar devices, including but not limited to aluminosilicate glass, alkali aluminosilicate glass, borosilicate glass, alkali boro Silicate glass, aluminoborosilicate glass, alkali aluminoborosilicate glass, soda lime glass and other suitable glasses. In certain embodiments, the thickness of the glass article may be less than or equal to about 3 mm, such as in the range of about 0.3 mm to about 2 mm, about 0.7 mm to about 1.5 mm, or about 1.5 mm to about 2.5 mm, inclusively All ranges and subranges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com