Anti-blocking scriber for test field and using method of anti-blocking scriber

A test field and scriber technology, applied in planting methods, applications, agriculture, etc., can solve the problems of time-consuming and labor-intensive, increase the labor intensity of staff, etc., and achieve the effect of convenient and quick operation, facilitate dredging, and ensure normal cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

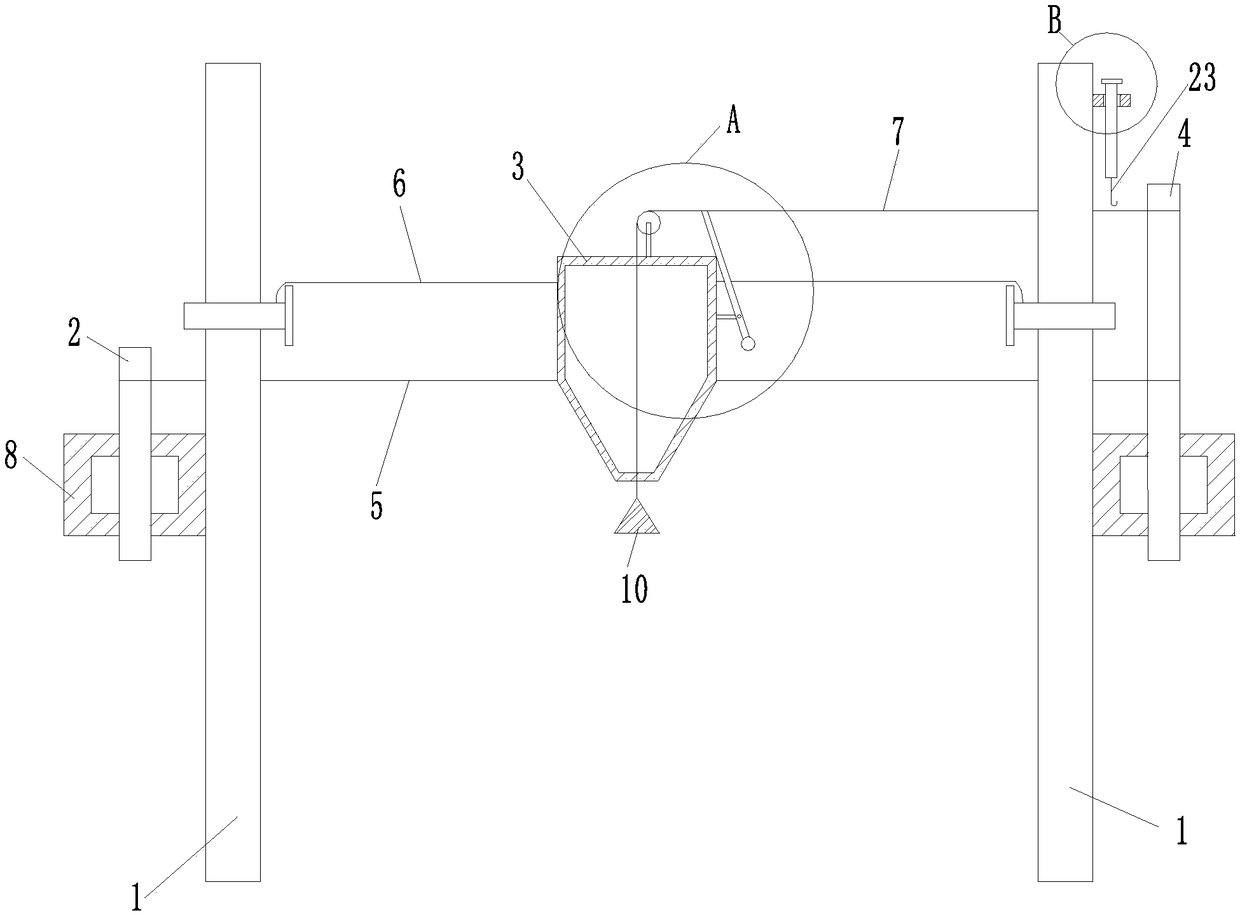

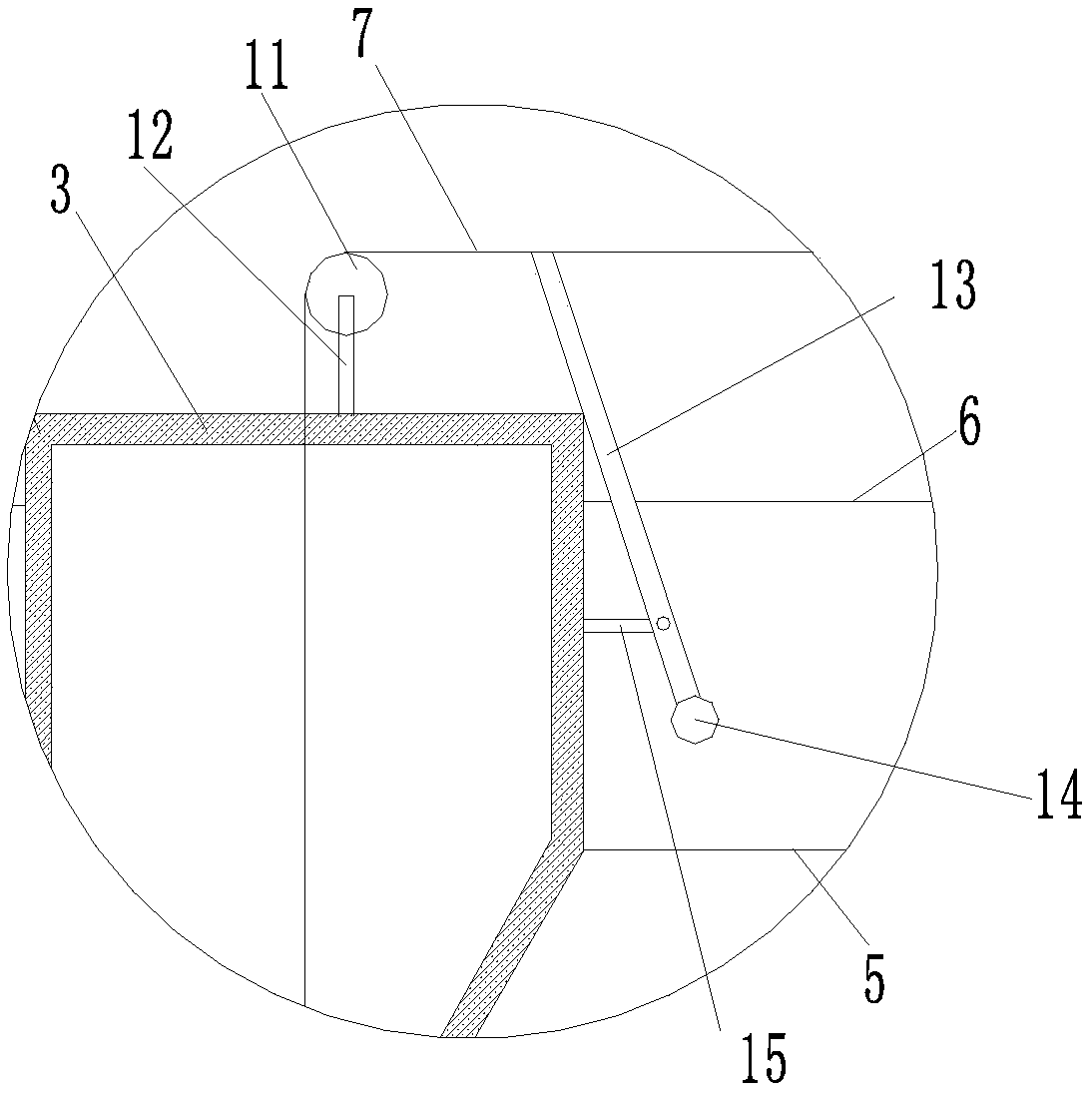

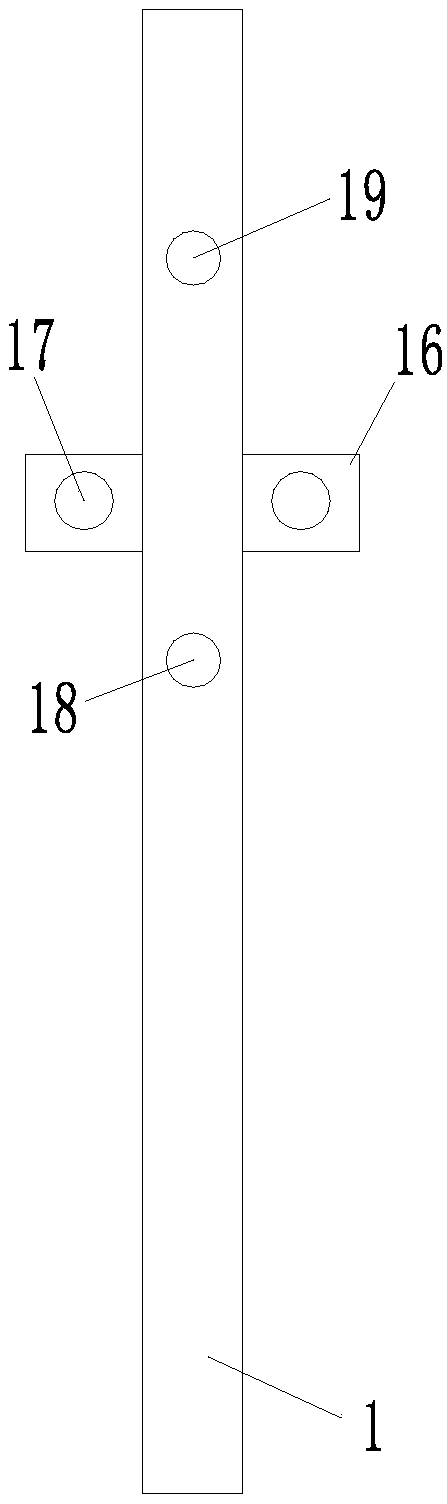

[0045] like Figure 1-7 As shown, a kind of anti-blocking marking device for a test field proposed in this embodiment includes an ash hopper 3 and a vertical pole 1, wherein the number of vertical poles 1 is provided with two, and a first pole is provided on the two vertical poles 1. The through hole 18 and the second through hole 19 are advantageous. In order to facilitate ash leakage, the bottom of the ash hopper 1 can be set as a cone, and the bottom end of the ash hopper 1 is provided with an ash outlet 32, and the outer wall of the ash hopper 1 is also provided with an ash outlet. Rope-through ring 31 is arranged, wherein the quantity of rope-through ring 31 can be set as two and is arranged symmetrically, and support plate 33 is also provided at the top of ash bucket 1; Ash bucket 3 is connected with vertical rod 1 by reciprocating mechanism, further Yes, the reciprocating mechanism may include a bracket 8, and further, there are two brackets 8, the brackets 8 are respec...

Embodiment 2

[0059] like Figure 8 As shown, other structures are the same as those in Embodiment 1, the difference is that the lifting mechanism of the ejector proposed in this embodiment can be a magnet 24, and the ejector is lifted and fixed by using the magnetic force of the magnet 24, which is very convenient and practical.

[0060] The specific usage method is as follows:

[0061] When in use, first fix the pole 1 at both ends of the test field;

[0062] The second wire rope 6 is passed through the rope ring 31, and the two ends of the second wire rope 6 are stretched into the fastening holes 91 of the first bolt 9 respectively, and the first bolt 9 is screwed into the first threaded hole 17. A bolt 9 is continuously screwed in, and the second wire rope 6 is fastened on the vertical pole 1;

[0063] A staff member rotates the first rotating shaft 2, along with the rotation of the first rotating shaft 2, drives the first steel wire rope 5 to move towards the direction close to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com