Combination removal apparatus of water lettuce

A water lotus and equipment technology, which is applied in the field of agricultural machinery, can solve the problems of high labor intensity, low cleaning efficiency, and difficulty in cleaning, and achieve the effects of reducing labor intensity, simple structure, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment proposes a low-cost and high-efficiency composite water lotus removal equipment to reduce the labor intensity of farmers.

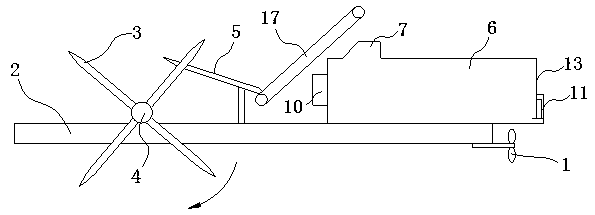

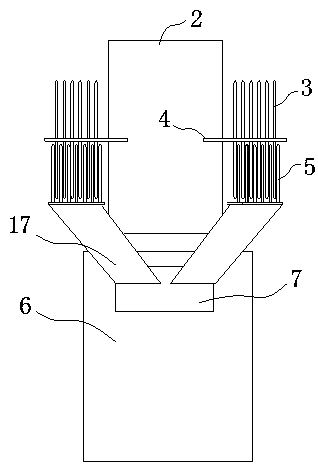

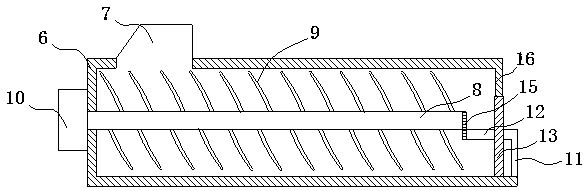

[0022] Such as Figure 1~5 As shown, the water floating lotus compound removal equipment of the present embodiment includes a floating body 2 provided with a propeller 1, a propeller driving mechanism, and two water floating lotus cleaning combs 3 located on both sides of the floating body 2, and the water floating lotus cleaning combs 3 are formed by Several parallel straight rod-shaped combs are formed. The water lotus removal combs 3 are multiple, and are radially fixed on the horizontal shaft 4. The horizontal shaft 4 is installed on the floating body, and the horizontal shaft 4 is driven by the horizontal shaft. The mechanism is connected, and the horizontal rotating shaft 4 is perpendicular to the direction of travel of the floating body 2; The water lotus removal comb 3 is the same, and the water lotus removal comb 5 has one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com