Surface art pattern processing device for furniture wooden door processing

A processing device, technology of wooden doors, applied in the direction of metal processing equipment, machine tools for surface polishing, grinding/polishing safety devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

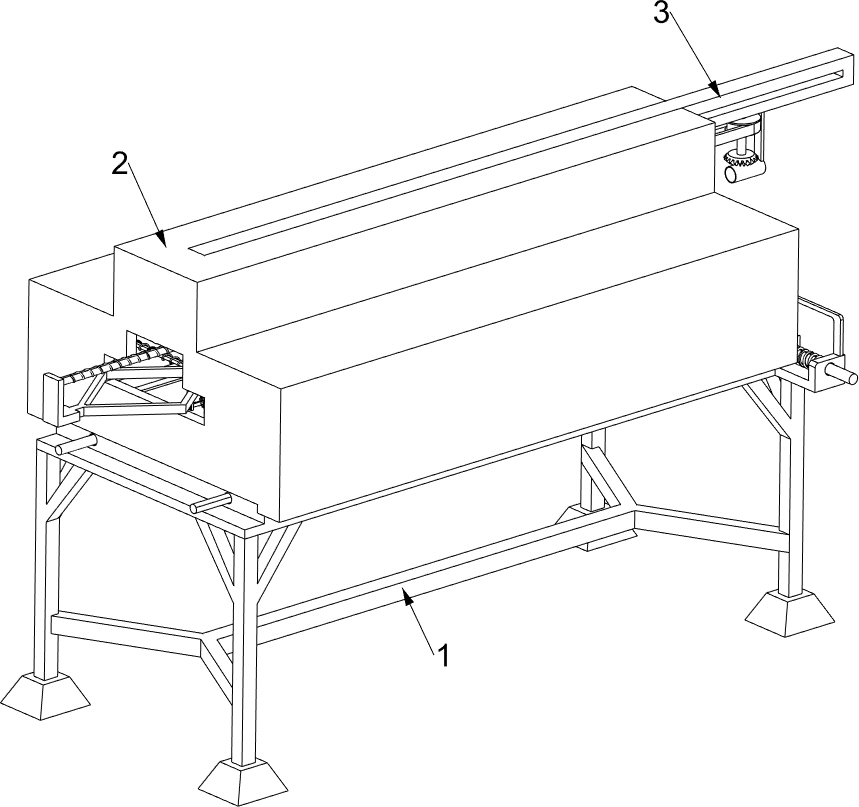

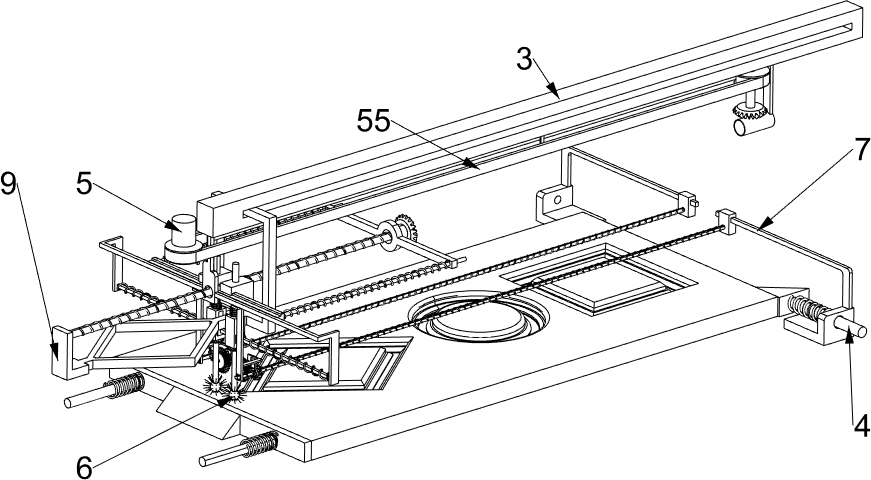

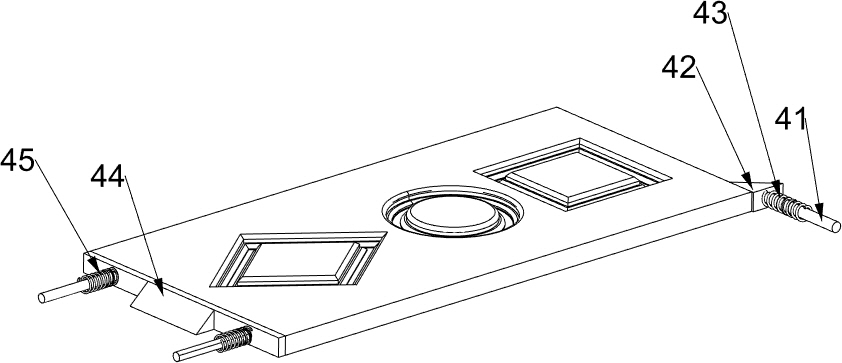

[0034] A surface art pattern processing device for furniture wooden door processing, such as Figure 1-9 As shown, it includes a first fixed frame 1, a workbench 2, a second fixed frame 3, a fixed mechanism 4, a reciprocating mechanism 5, a first cleaning mechanism 6 and an opening and closing mechanism 7, and a working mechanism is connected above the first fixed frame 1. Table 2, the inside of the workbench 2 is a cavity structure, the workbench 2 is used to place the furniture wooden door to be processed, the second fixed frame 3 is fixedly connected to the top of the workbench 2, the second fixed frame 3 is in the shape of a strip, and the workbench 2 The top is provided with a fixing mechanism 4 for fixing the furniture wooden door to be processed, the second fixed frame 3 is provided with a reciprocating mechanism 5, and the reciprocating mechanism 5 is provided with burrs and dust on the artistic pattern groove on the surface of the furniture wooden door to be processed....

Embodiment 2

[0042] On the basis of Example 1, such as Figure 10-11 As shown, it also includes a rotating mechanism 8, the rotating mechanism 8 is located on the fifth fixed frame 72, the rotating mechanism 8 includes a first bevel gear 81, a seventh fixed frame 82, a first nut 83, a first gear 84, a The second gear 85 and the second bevel gear 86, the top of the second rotating shaft 65 is fixedly connected with the first bevel gear 81, the first bevel gear 81 is located above the spherical brush 66, and the right side of the fifth fixed frame 72 is fixedly connected with the seventh fixed frame 82, the first screw rod 78 is threaded with a first nut 83, the first nut 83 is located at the left part of the first screw rod 78, the first nut 83 passes through the seventh fixing frame 82, and the first nut 83 is connected with a first gear 84, the first gear 84 is located on the right side of the seventh fixed frame 82, the first gear 84 is rotatably connected with the seventh fixed frame 82...

Embodiment 3

[0045] On the basis of Example 2, such as Figure 12-13As shown, it also includes a second cleaning mechanism 9, which is used to assist in polishing the groove of the rectangular art pattern on the surface of the furniture wooden door. The second cleaning mechanism 9 is arranged on the second fixed mount 3. The second cleaning mechanism 9 Including the second sliding frame 91, the diamond frame 92, the second screw rod 93, the second fixed rod 94, the sixth return spring 95, the third sliding frame 96, the third bevel gear 97, the eighth fixed frame 98, the second nut 99 and the fourth bevel gear 911, the left side of the second fixed frame 3 is slidingly connected with the second sliding frame 91, the second sliding frame 91 is in contact with the first fixed block 63, and the second sliding frame 91 is fixedly connected with a rhombus frame 92 , the rhombus frame 92 is a rhombus structure, the rhombus frame 92 passes through the workbench 2, the rhombus frame 92 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com