Composite cooking vessel with heat-accumulating function and manufacture method thereof

A composite material and manufacturing method technology, applied in special materials for cooking utensils, household appliances, kitchen utensils, etc., can solve the problems of fragile, slow heat conduction, etc., and achieve good thermal conductivity, excellent heat storage performance, and good anti-breaking performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only for explaining the present invention, and are not intended to limit the present invention.

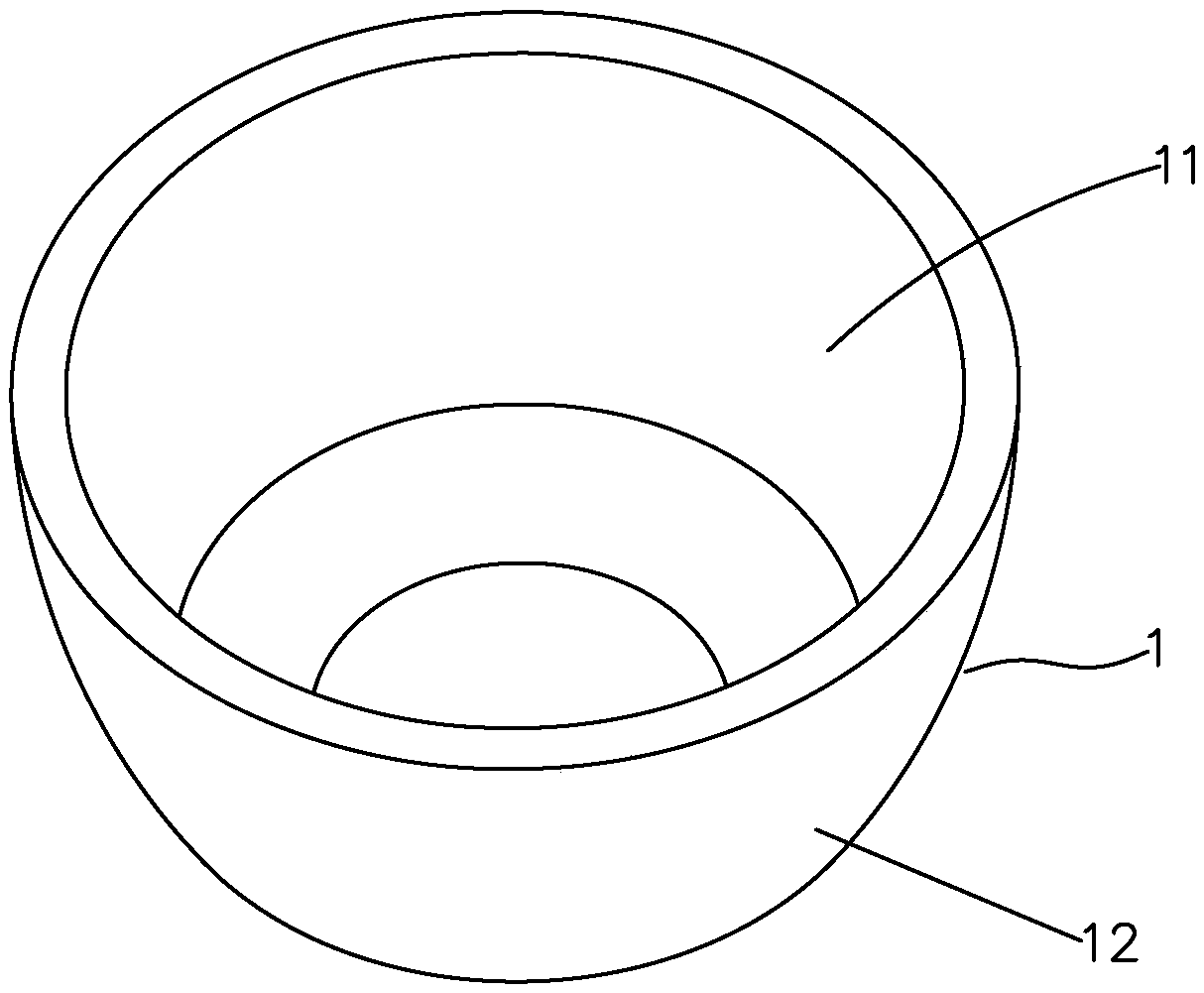

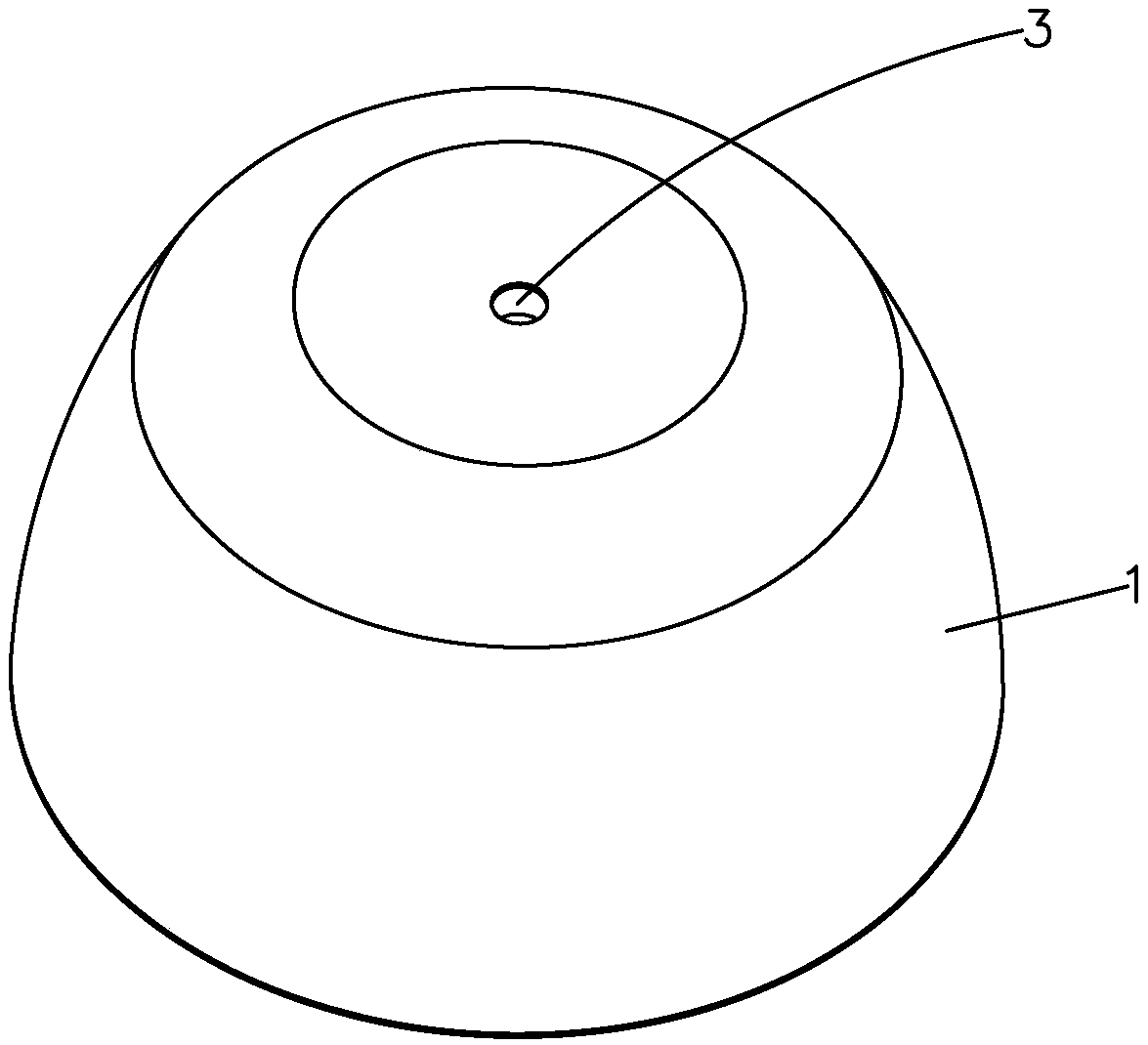

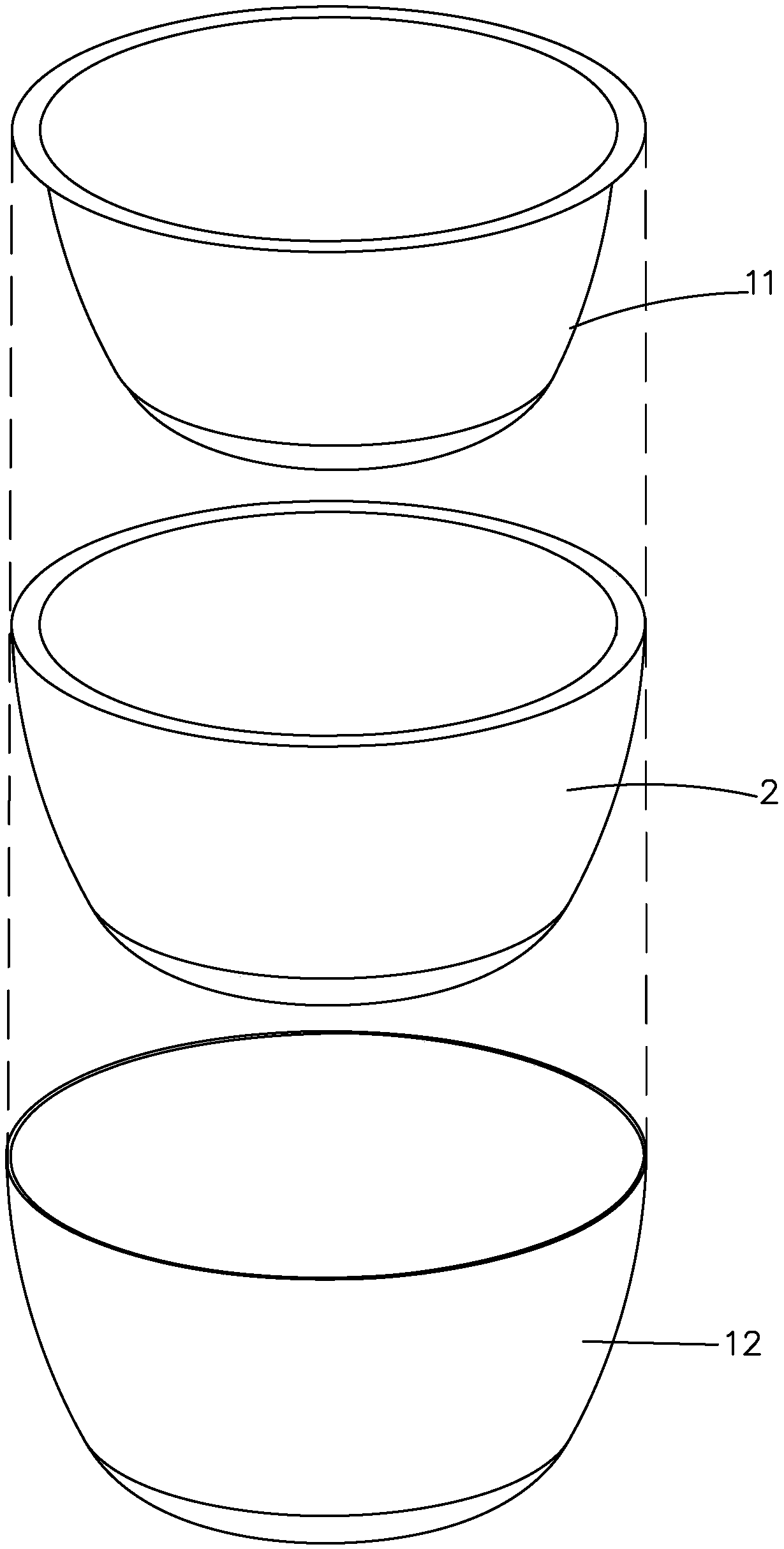

[0018] Such as Figure 1-4 As shown, a composite material pot with heat storage energy, it includes a metal shell 1 with an upper opening and a composite material interlayer 2, the metal shell 1 has a sealed accommodating cavity 11, and the bottom of the metal shell 1 is provided with There is an injection hole 12 , and the powder-shaped composite material is injected and filled into the accommodating cavity 11 of the metal shell through the injection hole 12 to form a composite material interlayer 2 .

[0019] A method for making a composite material pan with heat storage energy comprises the following steps:

[0020] 1. The inner wall plate 11 of the pot and the outer wall plate 12 of the pot are made of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com