Fixture for automobile coating finish paint technology

A coating and topcoat technology, which is applied in the field of fixtures in the automotive coating topcoat process, can solve the problems of low installation and disassembly efficiency, car paint residue, poor applicability, etc., to achieve convenient installation and disassembly, saving man-hours, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

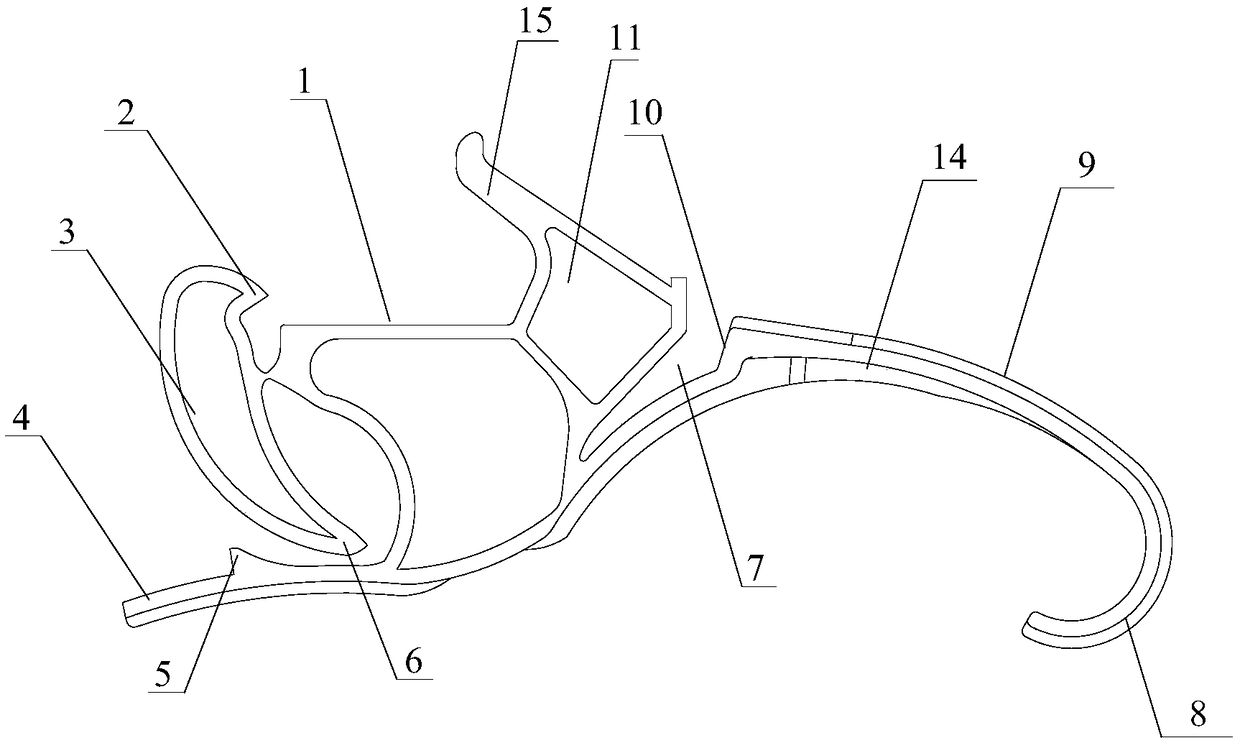

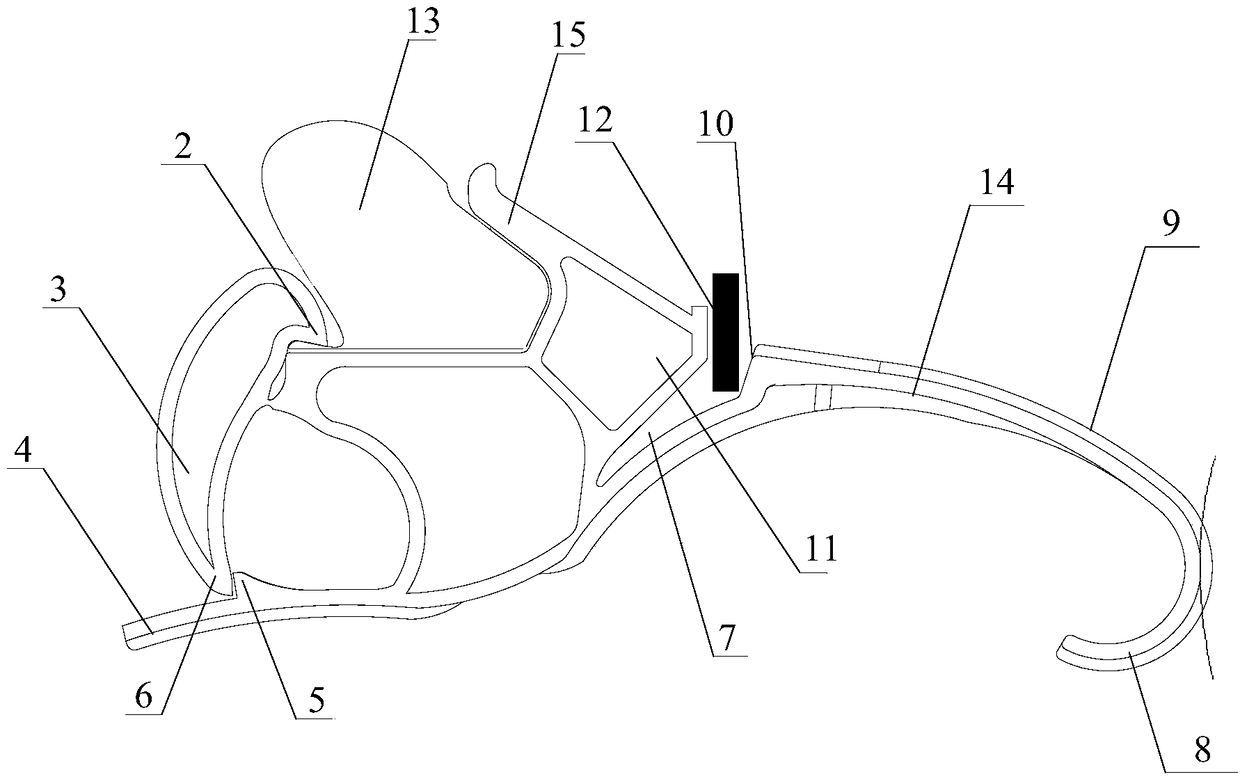

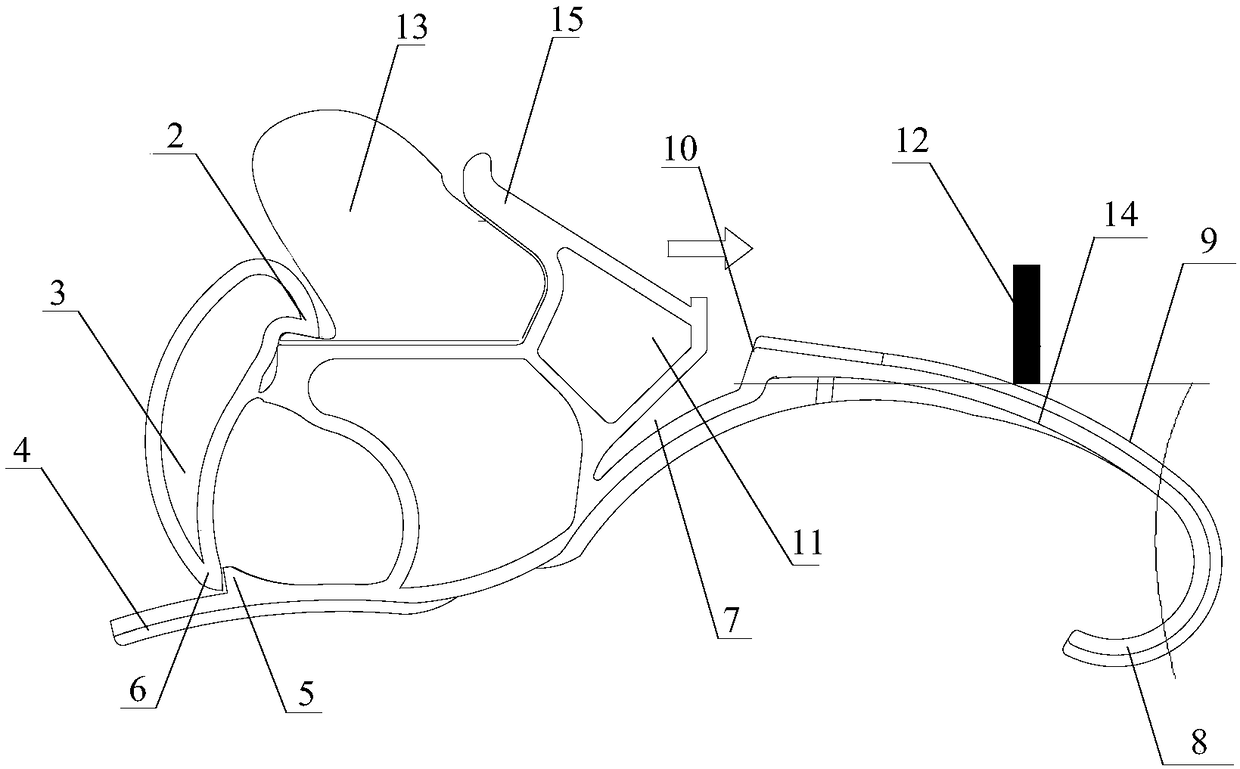

[0020] Such as figure 1 As shown, the present embodiment provides a clamp for the automobile painting topcoat process, the clamp is made of plastic material, and it includes an integrally formed clamping part 11, a first elastic clamping body 3 and a second elastic clamping body 14. Specifically, the middle part of the first elastic clamping body 3 is connected to one side of the clamping part 11, and its upper end forms a clamping opening 1 with the clamping part 11; the first elastic clamping body 3 can be clamped with it The connection point of the part 11 is used as a fulcrum to swing, and the clamping port 1 is locked by the swing. The second elastic clamping body 14 is connected to the other side of the clamping part 11, and a limiting groove 7 is formed between the second elastic clamping body 14 and the clamping part 11, and the second elastic clamping body is pressed down. Body 14 can change the opening of the limit groove 7. The lower end of the clamping part 11 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com