Centrifugal vibration impurity-filtering device for cereals

A centrifugal and grain-based technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of difficult impurity screening and low efficiency of the screening method, and achieve the effect of easy centralized collection of impurities, convenient and efficient use, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

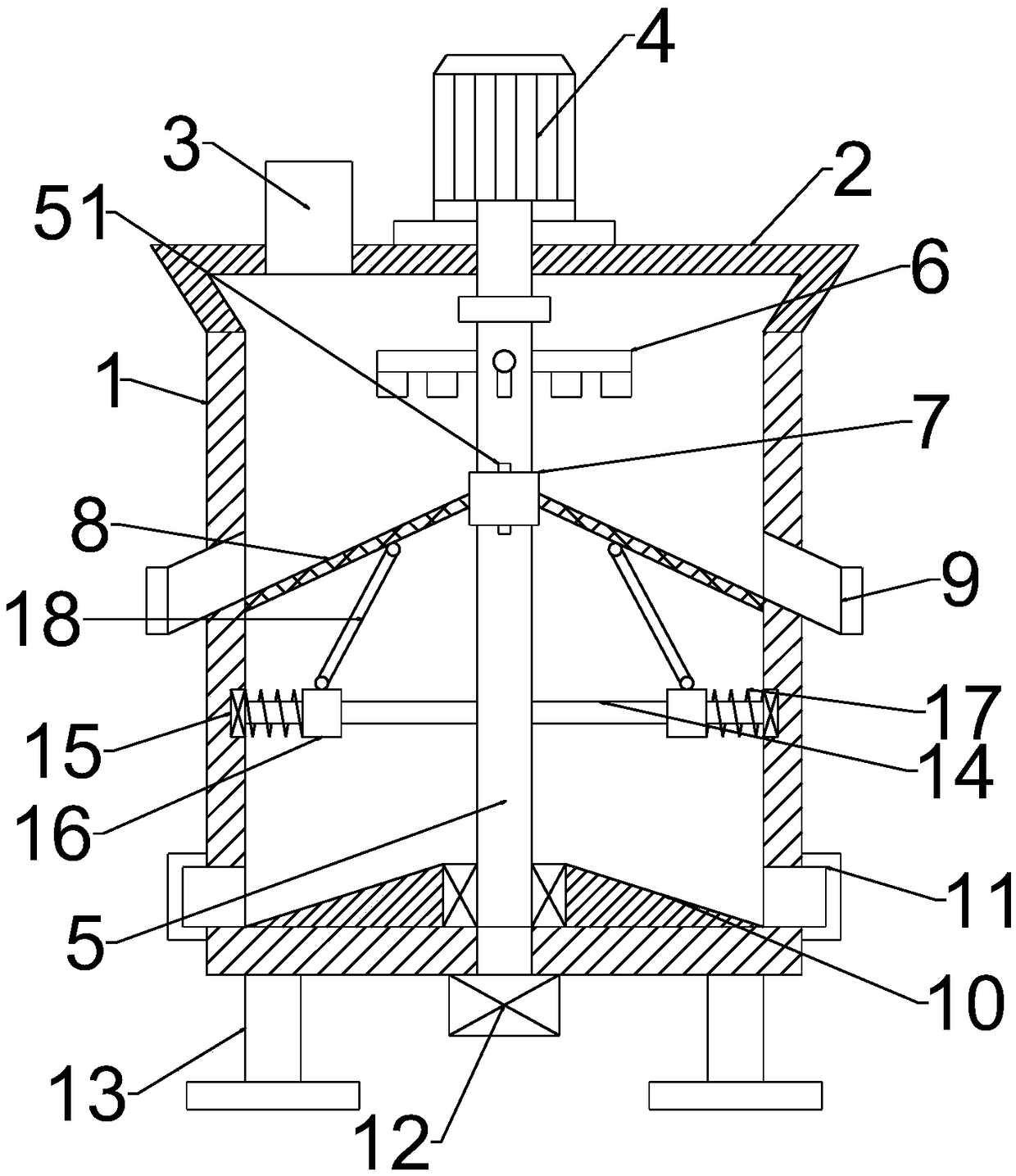

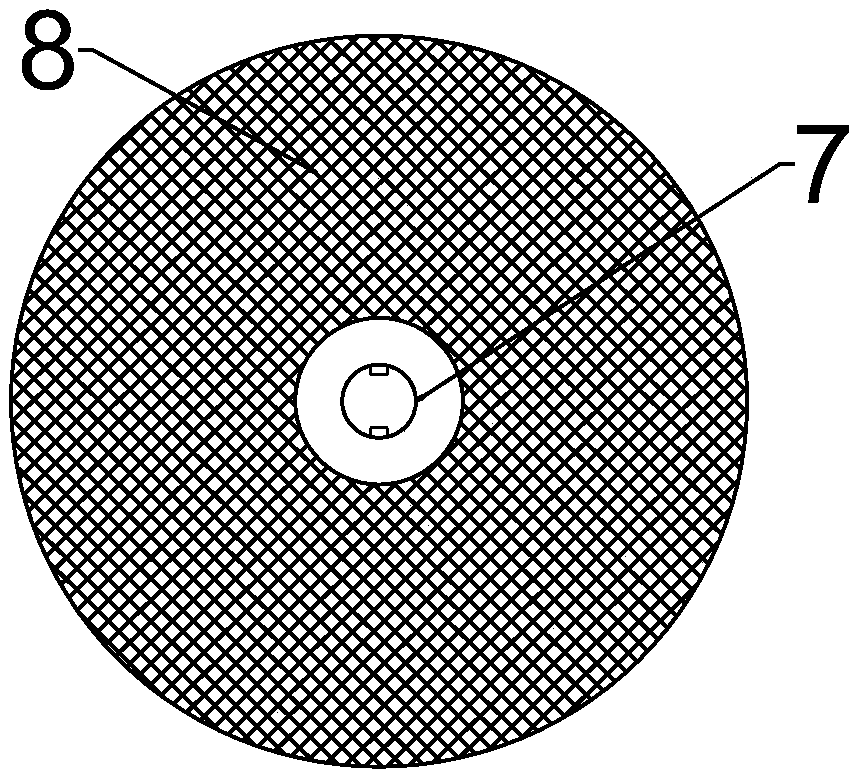

[0021] see Figure 1~2 , in an embodiment of the present invention, a centrifugal vibration filtering device for grains includes a housing 1, an upper cover 2, a motor 4, a rotating pipeline 5, an air injection pipeline 6, a filter screen 8 and a hot air blower 12, and the motor 4 The lower end is connected to the transmission through a coupling and the rotating pipe 5. The rotating pipe 5 is a hollow pipe with a closed upper end. The middle part of the rotating pipe 5 is symmetrically embedded with sliding grooves 51 on the front and rear sides. The peripheral connection of the rotating pipe 5 is provided with The first sliding ring 7, the first sliding ring 7 is slidingly connected with the rotating pipe 5, the inner wall of the first sliding ring 7 is provided with a protrusion that is slidingly matched with the sliding groove 51, and the first sliding ring 7. A filter screen 8 is welded on the periphery. The filter screen 8 is a circular truncated filter screen. The outer ...

Embodiment 2

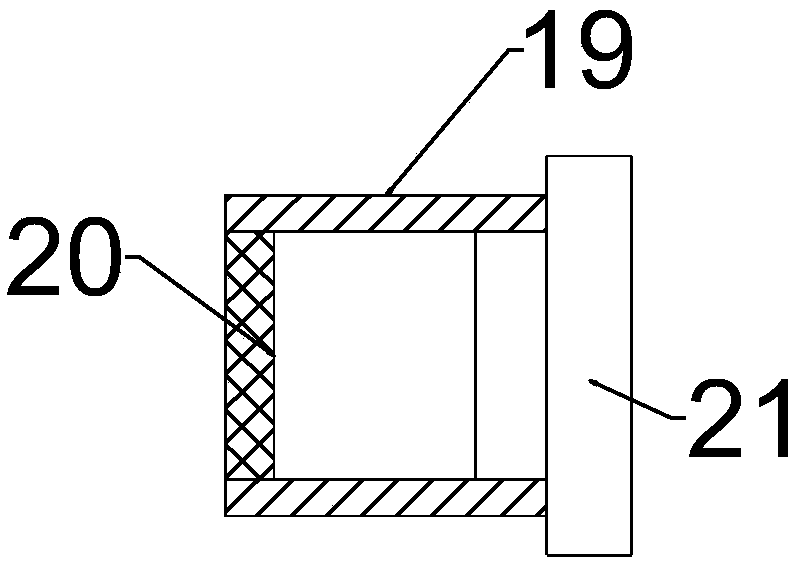

[0027] see image 3 , in an embodiment of the present invention, a centrifugal vibration filtering device for grains. On the basis of Embodiment 1, a threaded pipe 19 is arranged on the waste discharge pipe 11 through threaded joints, and the end of the threaded pipe 19 A metal mesh 20 is provided for welding, and a sealing plug 21 is provided at the outer end of the threaded pipe 19 through thread fit and movable connection.

[0028] In this way, the threaded pipe 19 can be flexibly connected with the miscellaneous pipe 11 during the air injection process. After the sealing plug 21 is unscrewed, the airflow is filtered and discharged through the metal mesh 20, which can ensure the exhaust. After the filtration is completed, unscrew the threaded pipe 19 to discharge Impurities.

[0029]The working principle of the present invention is: when in use, the grain is put into the casing 1 through the feeding pipe 3, the starting motor 4 drives the rotating pipe 5 to rotate, the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com