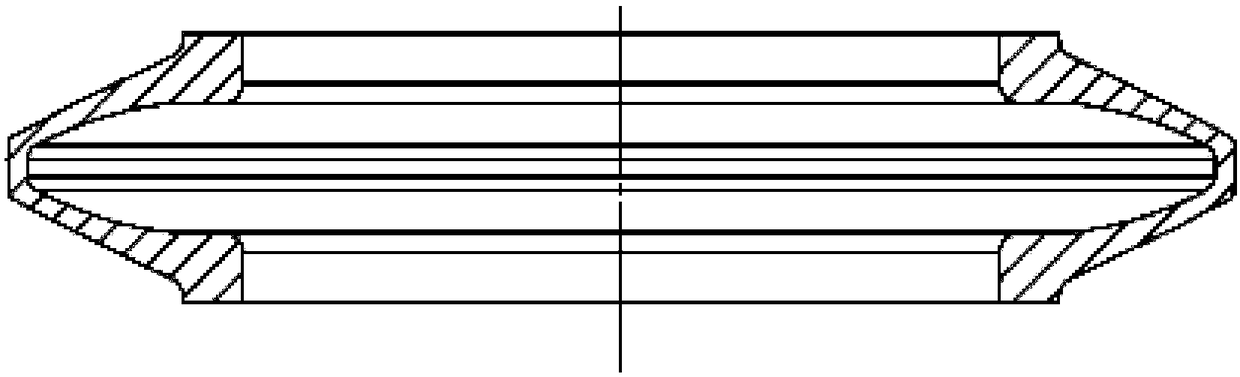

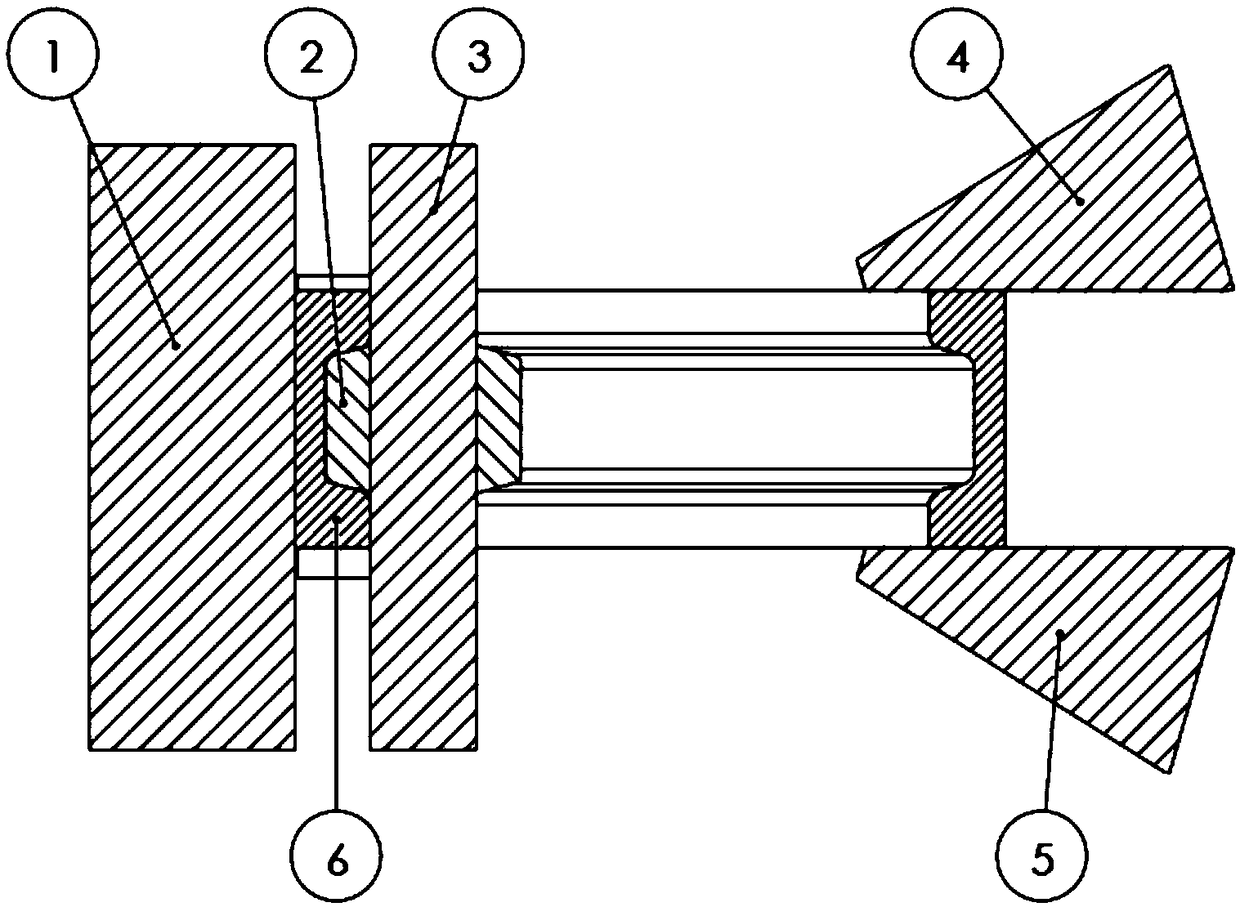

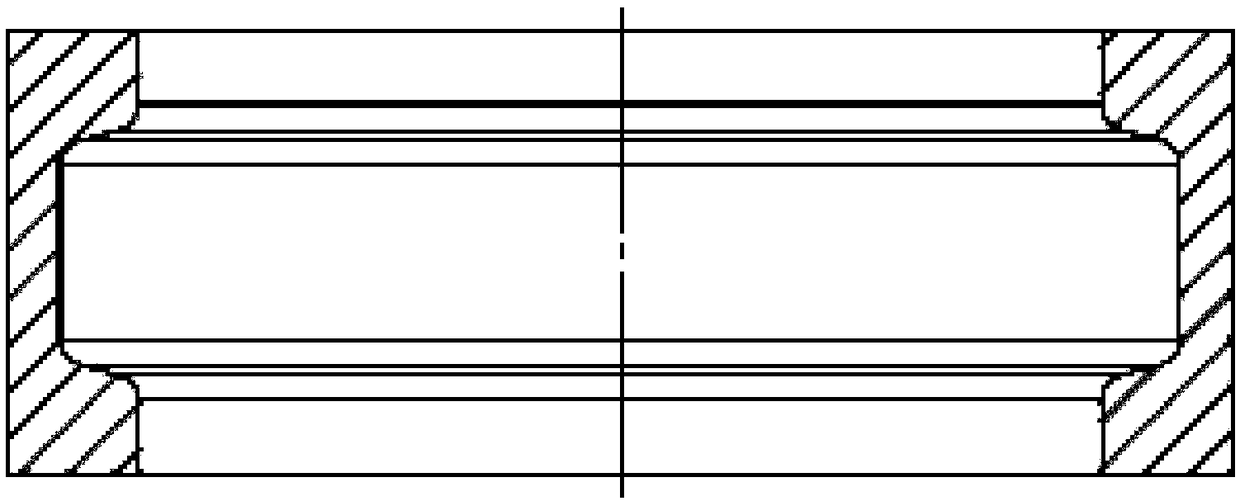

Preparation technology of intermediate blank of ring piece with C-type cross section

A preparation process and billet technology, which is applied in the field of intermediate billet preparation for C-section ring pieces, can solve the problems of difficult ring rolling process, excessive contact surface knots, and relatively high tonnage requirements of ring rolling mill equipment, and can reduce tonnage requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, a process for preparing the intermediate blank of a C-shaped cross-section ring, the steps of obtaining the workpiece by forging an alloy alloy ingot are as follows:

[0025] ①The alloy ingot is heated to 1160°C;

[0026] ② Upsetting the alloy ingot to 2 / 5 of the original height;

[0027] ③Punch the blank after upsetting, and then expand the hole to the diameter of the ring rolling machine +95mm;

[0028] ④ Use a ring rolling machine to grind the ring to the required size of the workpiece, and the deformation is 42%;

[0029] ⑤ Cool to room temperature.

[0030] The intermediate billet produced by the above process is stretched and finally forged by using the plastic deformation of the material. The yield strength of the forged ring forging reaches 361MPa, and the V-shaped notch Charpy impact test is done at -20°C. The impact energy The average value is 125J.

Embodiment 2

[0032] A process for preparing a C-shaped cross-section ring piece intermediate blank material. The process of obtaining a workpiece by forging an alloy alloy ingot is as follows:

[0033] ①The alloy ingot is heated to 1170°C;

[0034] ② Upsetting the alloy ingot to 1 / 2 of the original height;

[0035] ③Punch the blank after upsetting, and then expand the hole to the diameter of the ring rolling machine +100mm;

[0036] ④ The ring rolling machine is used to grind the ring to the required size of the workpiece, and the deformation is 48%;

[0037] ⑤ Air-cool to room temperature.

[0038] The intermediate blank produced by the above process is stretched and finally forged by using the plastic deformation of the material. The yield strength of the forged ring forging reaches 364MPa, and the Charpy impact test of the V-shaped notch is performed at -20°C. The average value is 170J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com