Soldering iron tip quick change system

A soldering iron tip and soldering iron technology, applied in soldering irons, metal processing equipment, welding equipment, etc., can solve the problems of easy error and long installation time, and achieve the effect of improving replacement efficiency, realizing automatic replacement, and avoiding manual operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

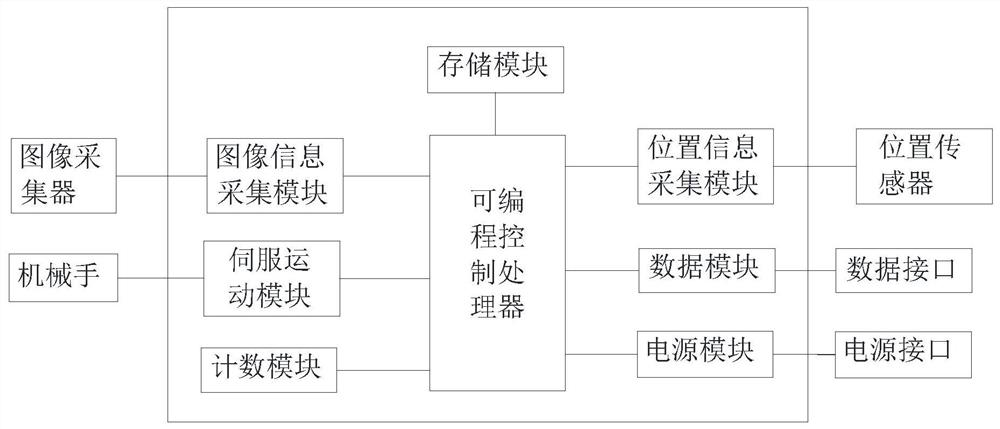

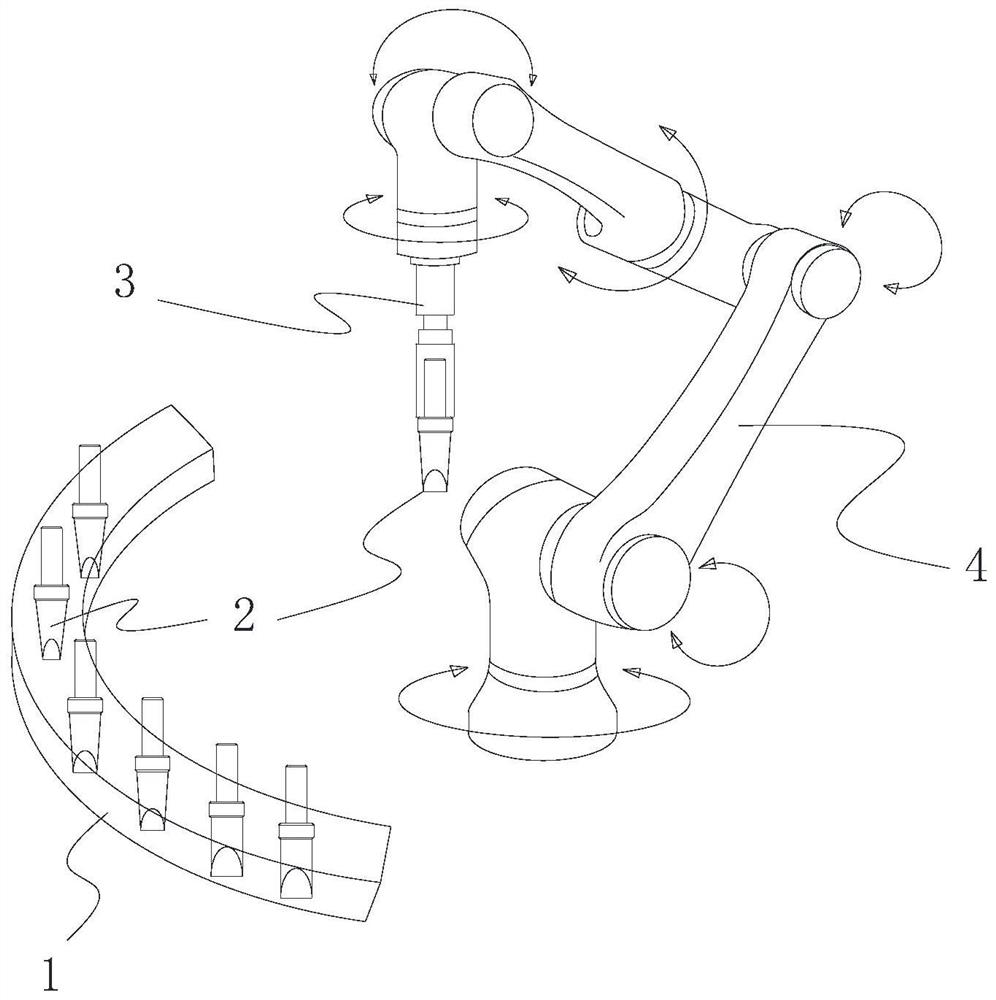

[0023] A soldering iron tip quick change system, such as figure 1 and figure 2 As shown, it includes a soldering iron tip storage bracket 1, a manipulator and a master control device. The soldering iron tip storage bracket 1 is provided with a storage slot, a position sensor and a clamping mechanism. There are several storage slots, and each storage slot can place a soldering iron head 2 correspondingly. The clamping mechanism is used to clamp and loosen the soldering iron head 2, which is convenient for the robot 4 to install and take out the soldering iron head 2. The clamping mechanism can be a cylinder. It is clamped in the form of adding a jacket. When the soldering iron 3 and the soldering iron head 2 are connected by thread locking, the clamping part of the jacket can be clamped up and down. Position information of the soldering iron tip 2 in the storage slot (including whether the soldering iron tip 2 is missing in the storage slot). The manipulator 4 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com