A method for rapid plate change of bronzing plates

A bronzing plate, fast technology, applied in the general parts of printing machinery, printing, printing machines and other directions, can solve problems such as affecting product quality, inaccurate corresponding positions of plates, etc., to improve product quality, save time, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

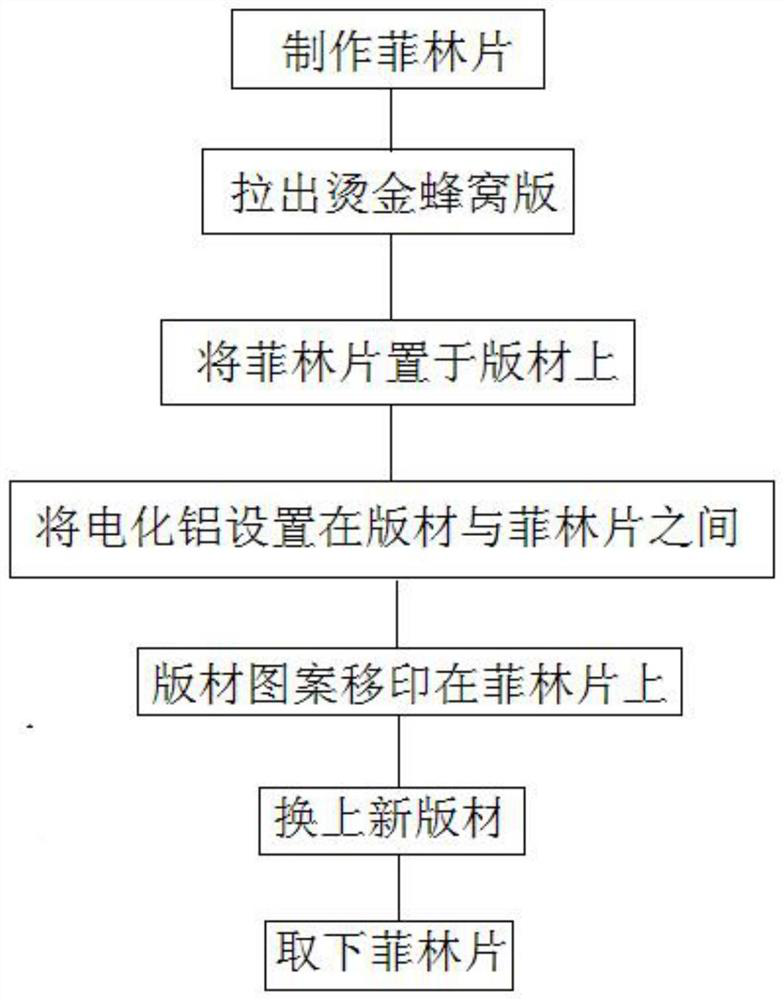

[0022] A kind of rapid version changing method of bronzing version, such as figure 1 The following steps are shown,

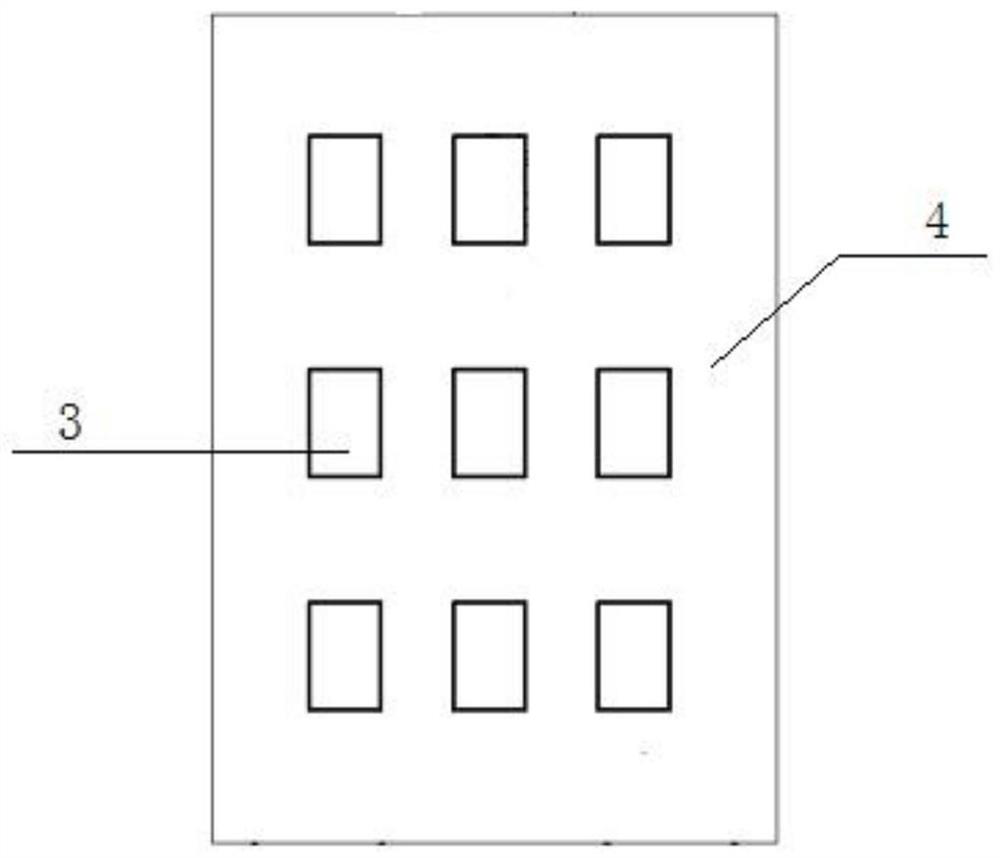

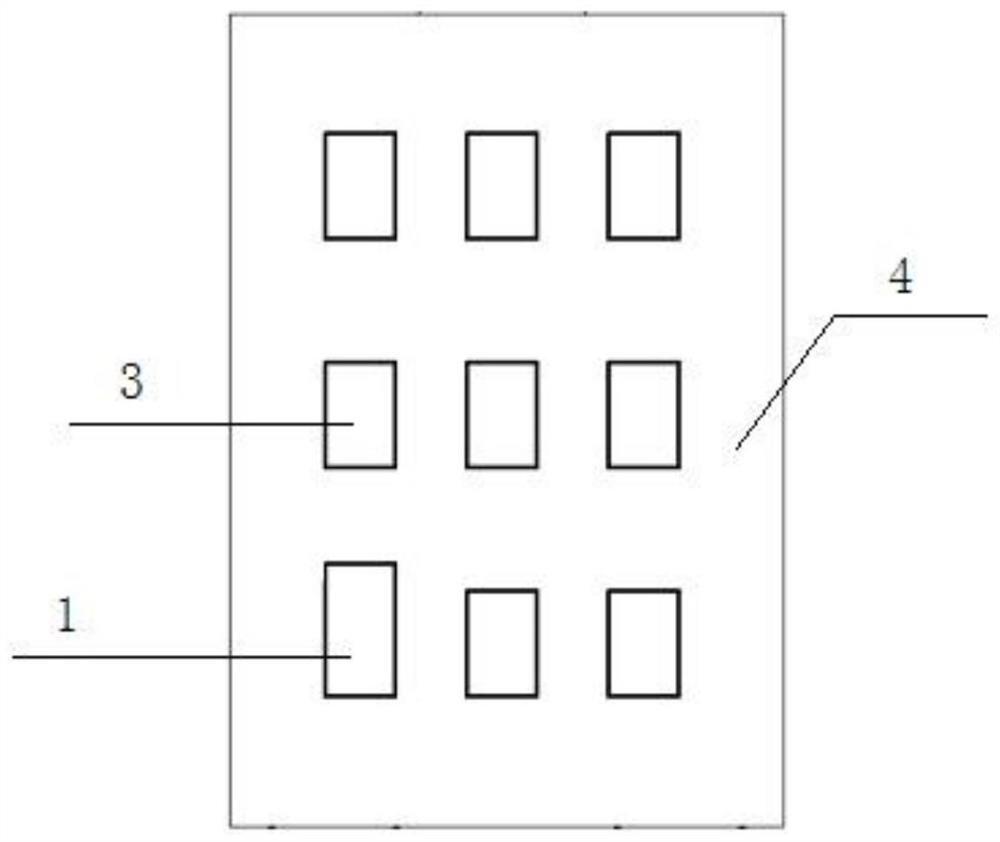

[0023] The first step, making film sheet 1, the width of described film sheet 1 is equal to the width of changed plate material 3, and the length of described film sheet 1 is greater than the length of changed plate material 3;

[0024] The second step is to pull out the bronzing honeycomb plate 4 in the automatic stamping machine;

[0025] In the third step, the film sheet 1 is placed on the plate material 3 that needs to be replaced, and one end of the film sheet 1 is fixed on the bronzing honeycomb plate 4 with glue;

[0026] The fourth step is to take the hot stamping anodized aluminum 2 and arrange it between the plate material 3 and the film sheet 1, and align the hot stamping surface of the hot stamped anodized aluminum 2 with the film sheet 1 upward;

[0027] The fifth step is to press the film sheet 1, and use the temperature of the plate material 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com