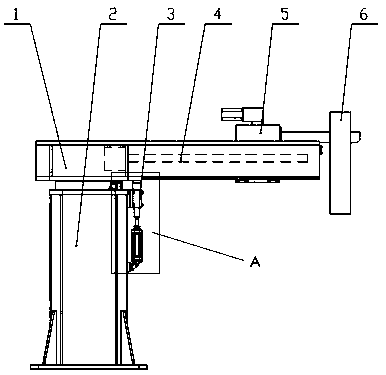

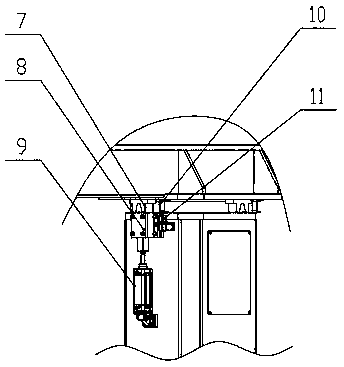

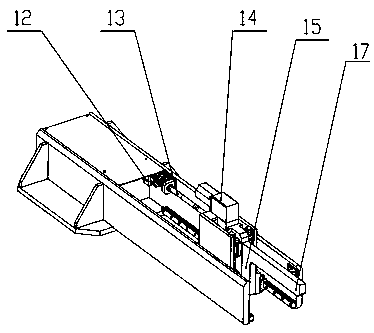

Automatic loading method and device for transverse shear line for silicon steel coiled materials

An automatic feeding and cutting line technology, applied in the direction of storage devices, transportation and packaging, etc., can solve the problems of inconvenient operation, instability, accidents, etc., improve accuracy and loading efficiency, reduce damage, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the application according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. In the following description, different "an embodiment" or "an embodiment" do not necessarily refer to the same embodiment, and in addition, specific features, structures, or characteristics of one or more embodiments may be combined in any suitable form.

[0044] In the present invention, the driving mechanism is a driving device that can be rotated and driven and can determine a specific position, such as a servo motor, a motor positioned with a limit switch, a proximity switch or a photoelectric switch, and the kinetic energy of the motor is changed through a gear mechanism and has a measuring gear mechanism The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com