Gear and rack elevator

A rack and pinion and elevator technology, applied in the elevator field, can solve the problems such as the inability to isolate the car, troublesome motor maintenance, and poor comfort, and achieve low noise and vibration, good economy, and fast delivery time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The rack and pinion elevator in this embodiment includes a transmission assembly and a carrier, the transmission assembly drives the carrier to move, and the carrier can be a car or a platform.

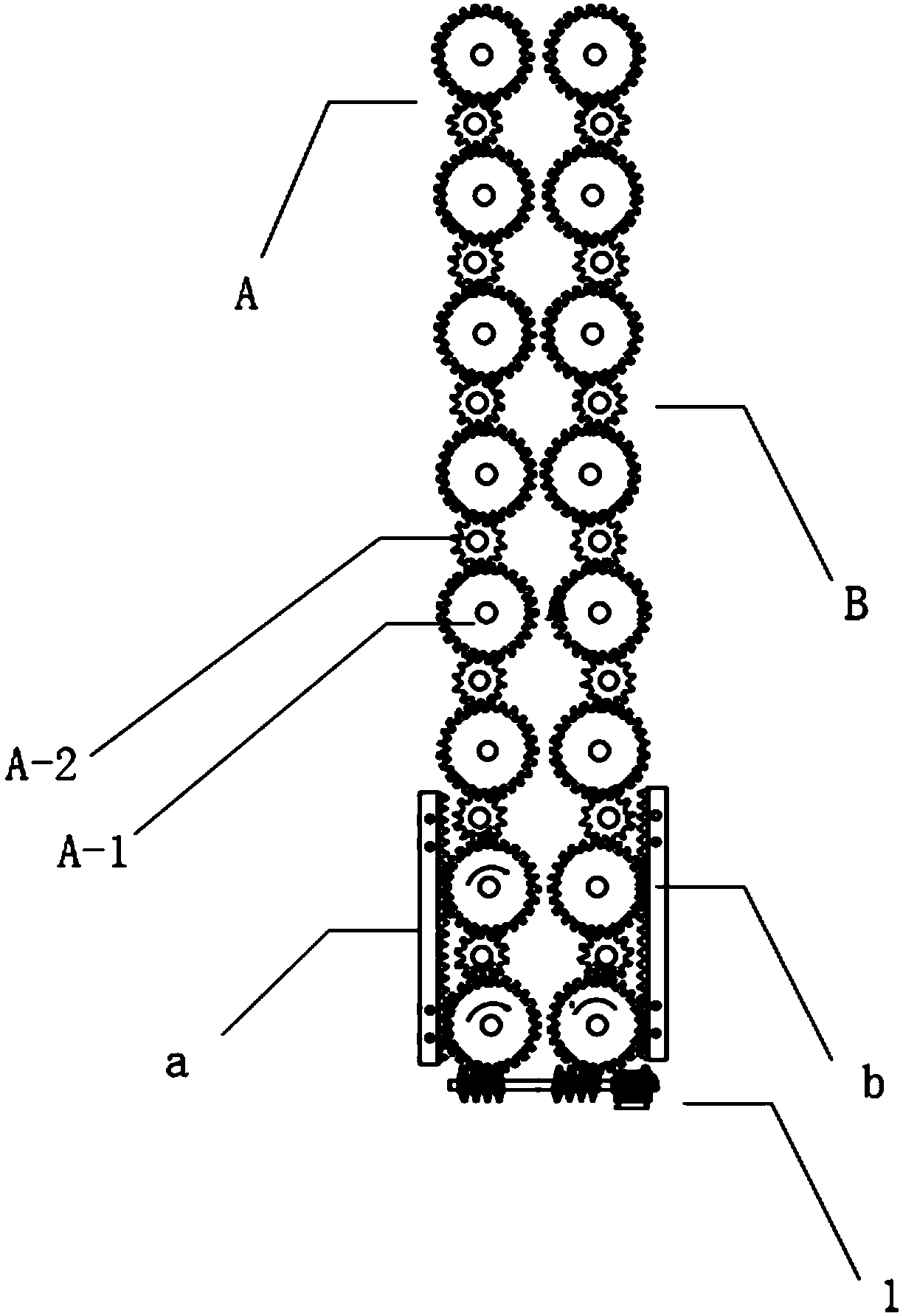

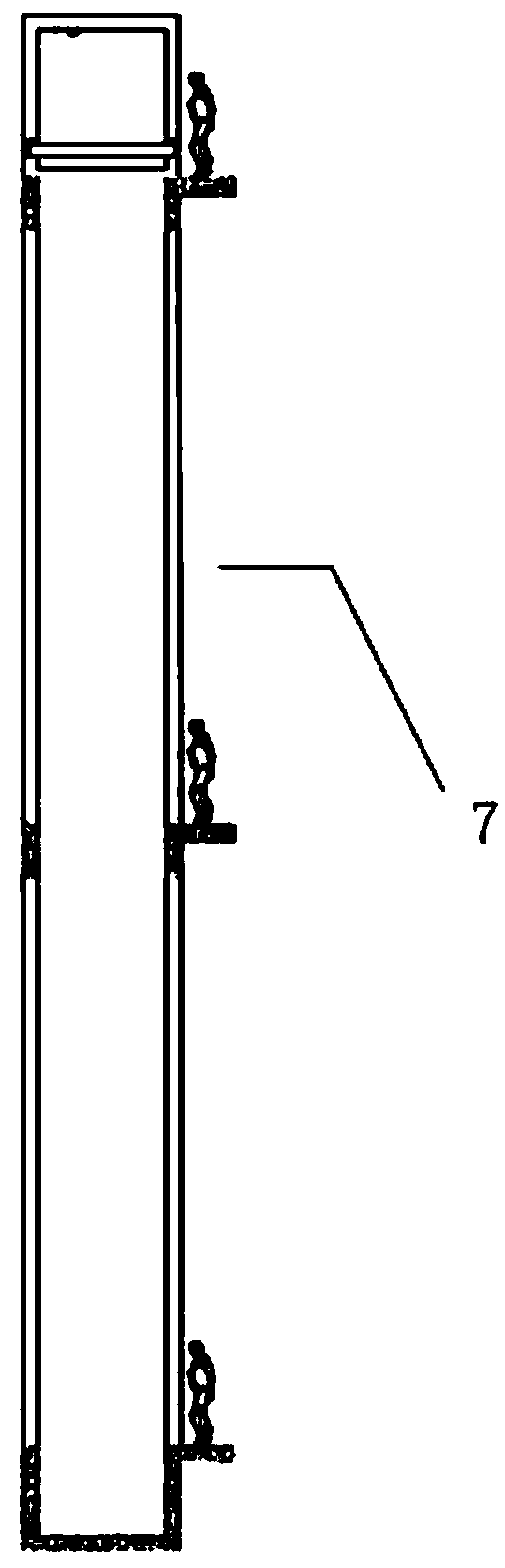

[0029] Such as figure 1 and 3 As shown, the transmission assembly includes a gear set A, a gear set B and a driving member 1 installed and fixed in the hoistway. The carrier is provided with a rack a and a rack b for meshing with the gear set A and the gear set B. The rack a and rack b are racks with tooth patterns on one side, the length of rack a and rack b is adapted to the height of the carrier, so that the length of rack a and rack b is less than or equal to the height of the carrier, The rack a and the rack b are bolted and fixed to the carrier body by opening through holes.

[0030] Among them, the gear set A includes a plurality of transmission gears A-1 arranged in sequence along the vertical direction of the hoistway, and a reversing gear A-2 is arranged between adj...

Embodiment 2

[0034] The rack and pinion elevator of this embodiment differs from Embodiment 1 in that:

[0035] Such as Figure 4 As shown, the reversing gear 2-1 can be selected from the same gear as the transmission gear model, and the meshing angle can be selected properly, and the meshing position can be installed properly; compared with embodiment 1, only one type of gear can be purchased and installed. Save time and effort.

[0036] For other structures, refer to Embodiment 1.

Embodiment 3

[0038] The rack and pinion elevator of this embodiment differs from Embodiment 1 in that:

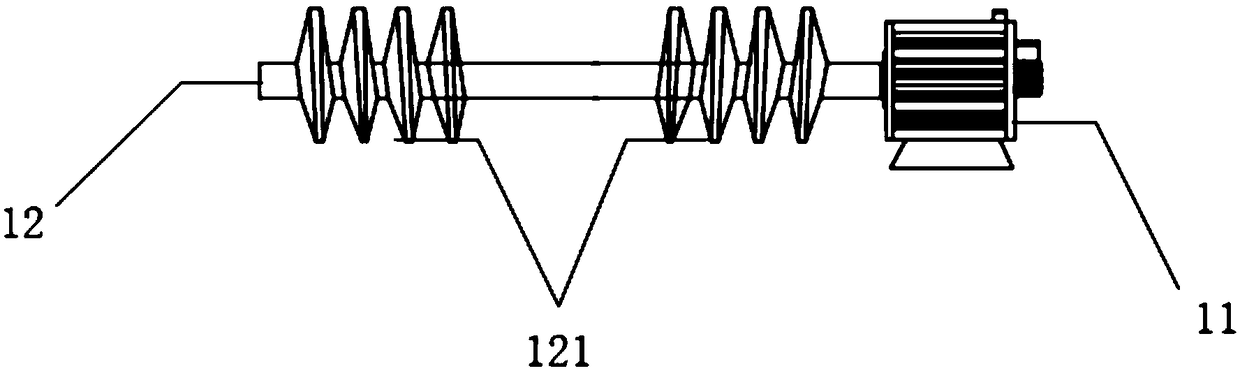

[0039] Such as Figure 5 As shown, the driving part 3-1 uses two motors, each motor has a worm, and each worm is provided with a set of helical teeth to drive each gear set respectively. When installed, the helical teeth of the worm rotate in the opposite direction. Compared with Embodiment 1, when one of the motors fails, the other motor can continue to support the operation of the elevator for a short time.

[0040] For other structures, refer to Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap