Novel magnetron sputtering device

A magnetron sputtering device and a new type of technology, which are applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problems of waste, target atom shedding, uneven magnetic field distribution, etc. efficiency, avoid waste, and improve the effect of film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

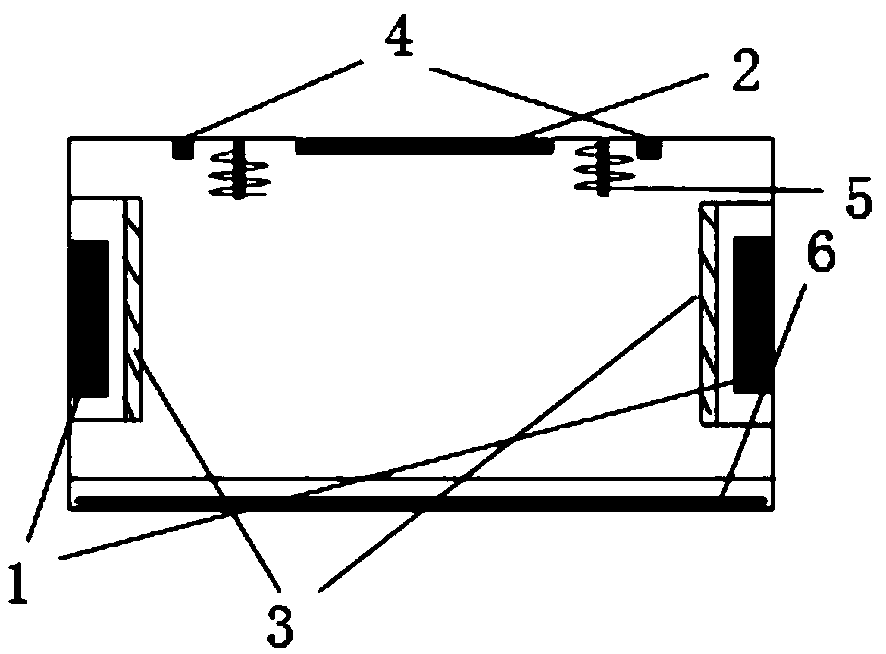

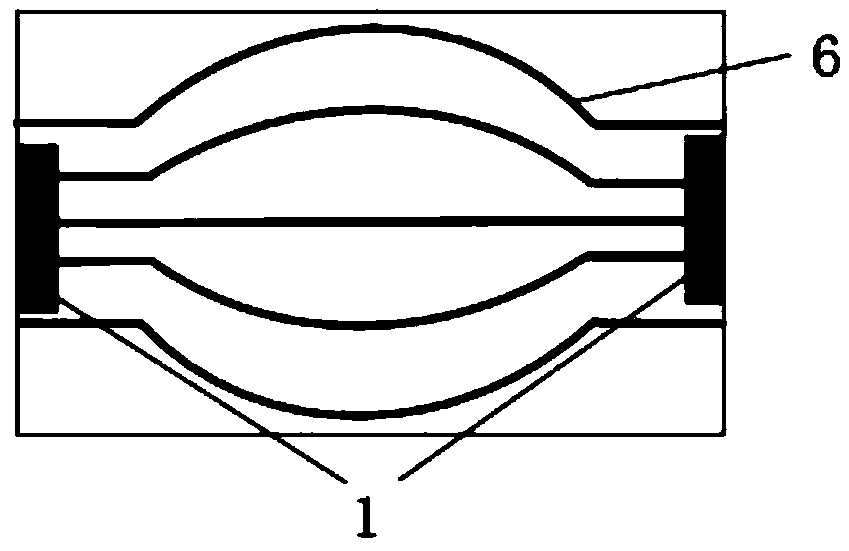

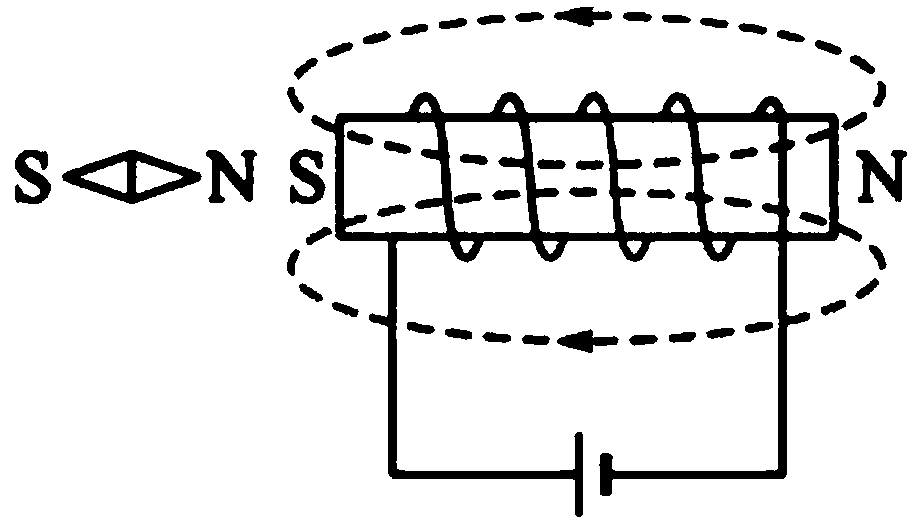

[0019] Such as Figures 1 to 3 As shown, a new type of magnetron sputtering device includes a target 1 located in the chamber and a substrate 2 that can move back and forth. A protection valve 3 is provided directly in front of the target 1, and the process position of the substrate 2 is on both sides. The first solenoids 4 are respectively provided, and the first solenoids 4 are made by winding electric wires on the outer peripheral side of the hollow tube in one direction, and the side of the first solenoids 4 facing away from the base plate 2 corresponds to The process position of the substrate 2 is provided with a laser positioner 5, and the protection valve 3 and the laser positioner 5 are both connected to the controller, and the controller is used to detect that the substrate 2 moves to the process position when the laser positioner 5 receives control the protection valve 3 to open, otherwise the protection valve 3 remains normally closed. The bottom of the chamber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com