Low-VOC (volatile organic compounds) artificial leather and preparation method thereof

A technology of artificial leather and resin layer, which is applied in the field of synthetic leather, can solve the problems of volatilization of VOC and environmental pollution, and achieve the effects of reducing the amount of use, improving the smoothness, and protecting the human body from harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

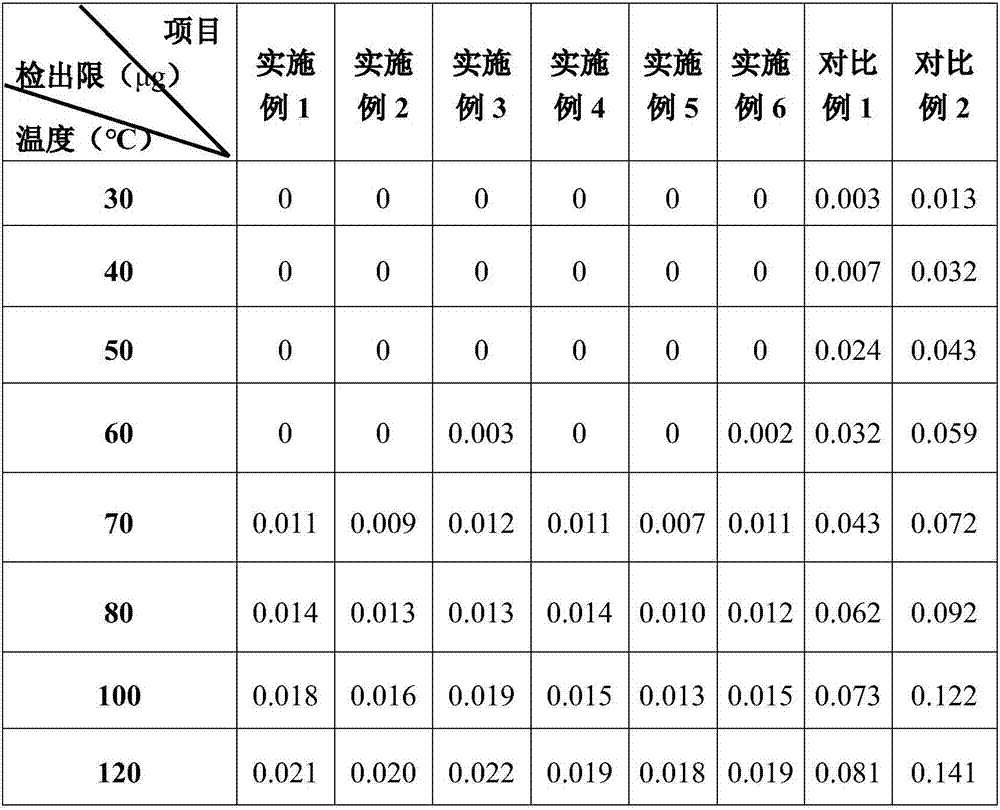

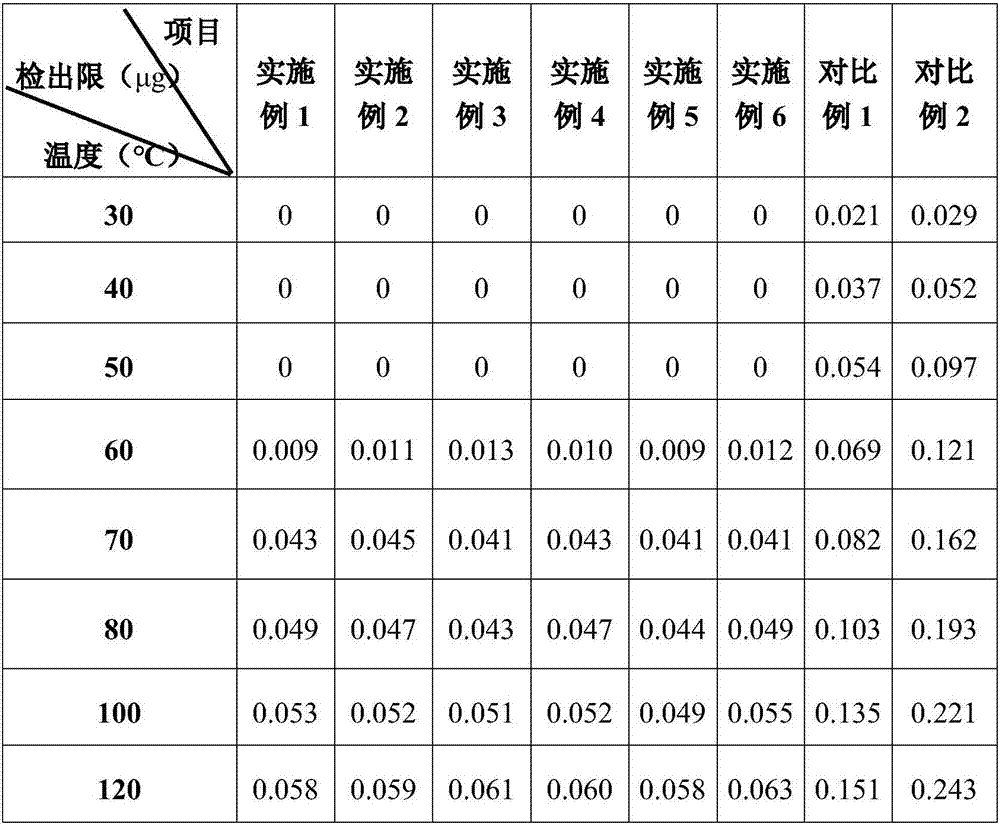

Examples

Embodiment 1

[0026] Low VOC artificial leather, including the first resin layer, the second resin layer and the base fabric layer from top to bottom, the resin layer is composed of polyurethane material, thickener, defoamer and nano-zinc oxide, the first resin layer and the second Both the two resin layers and the second resin layer and the base cloth layer are bonded by an adhesive layer.

[0027] Raw material formula: calculated in parts by mass, the polyurethane material is 90 parts of water-based polyurethane, the thickener is 0.5 parts of polyacrylamide, and the defoamer is 0.2 parts of polyether-modified organosiloxane defoamer and polysiloxane The mixture of defoamers, 3 parts of nano-zinc oxide.

[0028] The preparation method of low-VOC artificial leather comprises the following specific steps:

[0029] S1: Weigh the polyurethane material, thickener and nano zinc oxide, mix 30% of the total mass of the thickener formula with the polyurethane material, stir for 30 minutes, then ad...

Embodiment 2

[0036] Low VOC artificial leather, including the first resin layer, the second resin layer and the base fabric layer from top to bottom, the resin layer is composed of polyurethane material, thickener, defoamer and nano-zinc oxide, the first resin layer and the second Both the two resin layers and the second resin layer and the base cloth layer are bonded by an adhesive layer.

[0037] Raw material formula: Calculated in parts by mass, the polyurethane material is 88 parts of water-based polyurethane, the thickener is a mixture of 0.6 parts of polyacrylamide and polyurethane thickener, and the defoamer is 0.4 parts of polyether-modified organosiloxane A mixture of foaming agent and high-carbon alcohol defoaming agent, 4 parts of nano-zinc oxide.

[0038] The polyurethane material is one or more of water-based polyurethane, polyethylene terephthalate, polybutylene terephthalate, and the thickener is polyacrylamide, polyurethane thickener, aluminum silicate One or more, the def...

Embodiment 3

[0047] Low VOC artificial leather, including the first resin layer, the second resin layer and the base fabric layer from top to bottom, the resin layer is composed of polyurethane material, thickener, defoamer and nano-zinc oxide, the first resin layer and the second Both the two resin layers and the second resin layer and the base cloth layer are bonded by an adhesive layer.

[0048] Raw material formula: calculated in parts by mass, the polyurethane material is 92 parts of polybutylene terephthalate, the thickener is a mixture of polyacrylamide and aluminum silicate 0.6 part, and the defoamer is 0.5 part of polysiloxane defoamer Foaming agent, 6 parts of nanometer zinc oxide.

[0049] The preparation method of low-VOC artificial leather comprises the following specific steps:

[0050] S1: Weigh the polyurethane material, thickener and nano zinc oxide, mix 30% of the total mass of the thickener formula with the polyurethane material, stir for 30 minutes, then add 30% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com