Marine surface garbage disposal device

A water surface garbage and treatment device technology, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of high cost of marine garbage cleaning and transportation, high cost of marine garbage treatment, and harsh working environment, so as to reduce the labor intensity of workers , easy to decompose, improve the effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

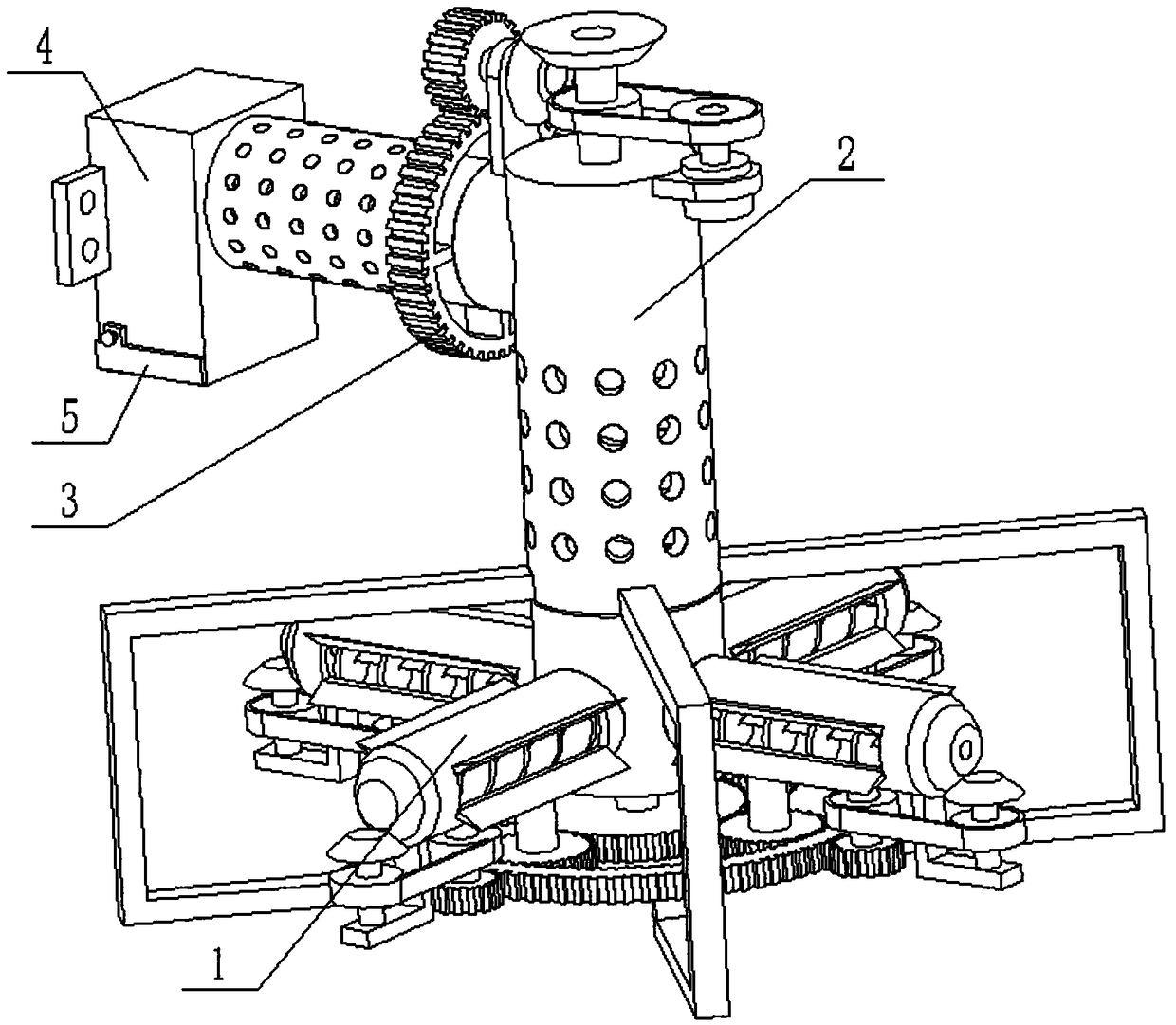

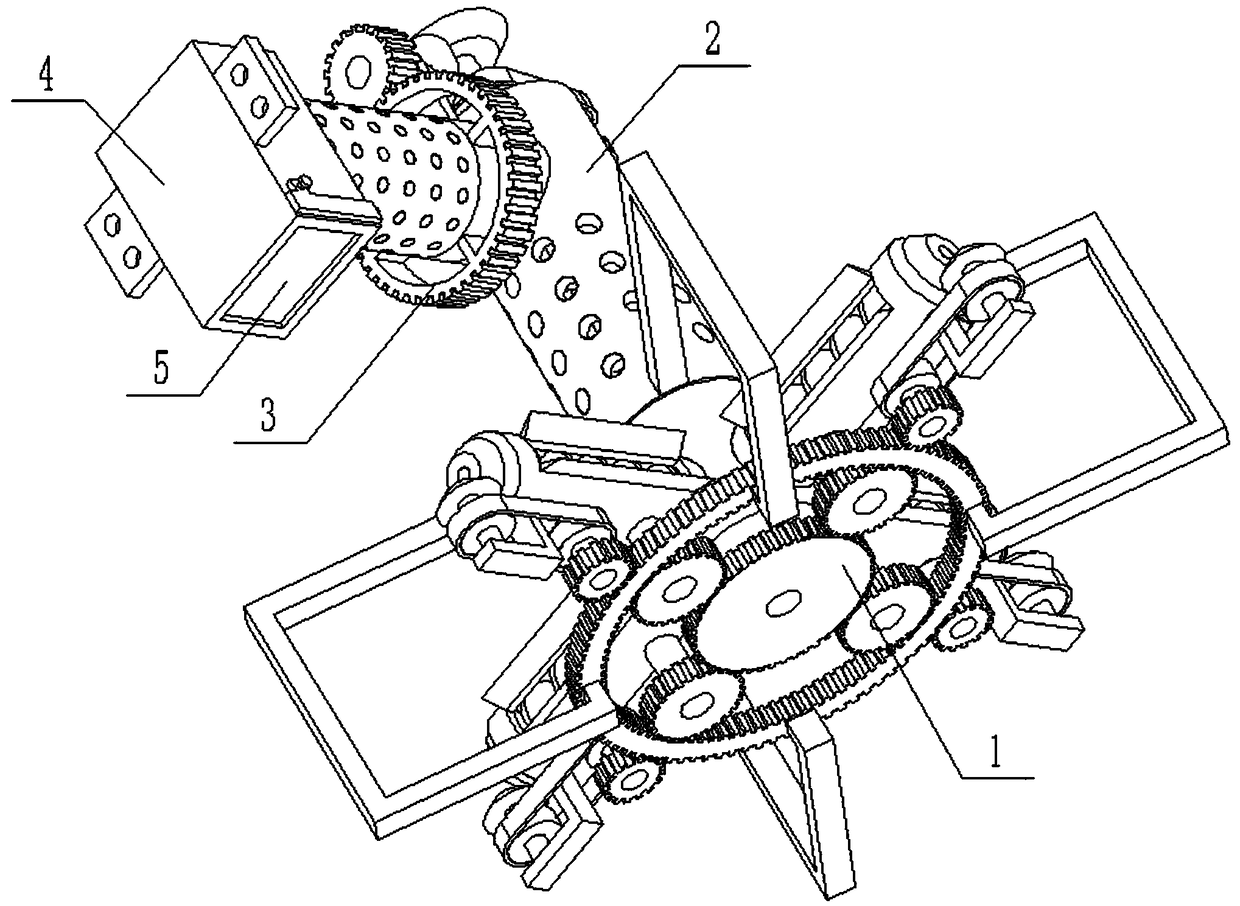

[0027] Combine below Figure 1-9 Describe this embodiment, a marine water surface garbage treatment device, including a garbage cleaning part 1, a garbage conveying cylinder 2, a garbage crushing cutter head 3, a garbage collection box 4 and a discharge plate 5, and the garbage cleaning part 1 includes a garbage flow Through the cylinder 1-1 and the garbage suction piece 1-2; the upper end of the garbage flow through the cylinder 1-1 is hollowed out, and there are four garbage suction pieces 1-2, and the four garbage suction pieces 1-2 surround the garbage flow through the cylinder 1- The axis of 1 is evenly arranged on the outer end surface of the garbage flow-through cylinder 1-1, and the four garbage suction parts 1-2 are all communicated with the interior of the garbage flow-through cylinder 1-1; when the garbage cleaning part 1 is in use, The present invention is fixed on one side of the hull, the present invention can be provided with a plurality of, respectively fixed o...

specific Embodiment approach 2

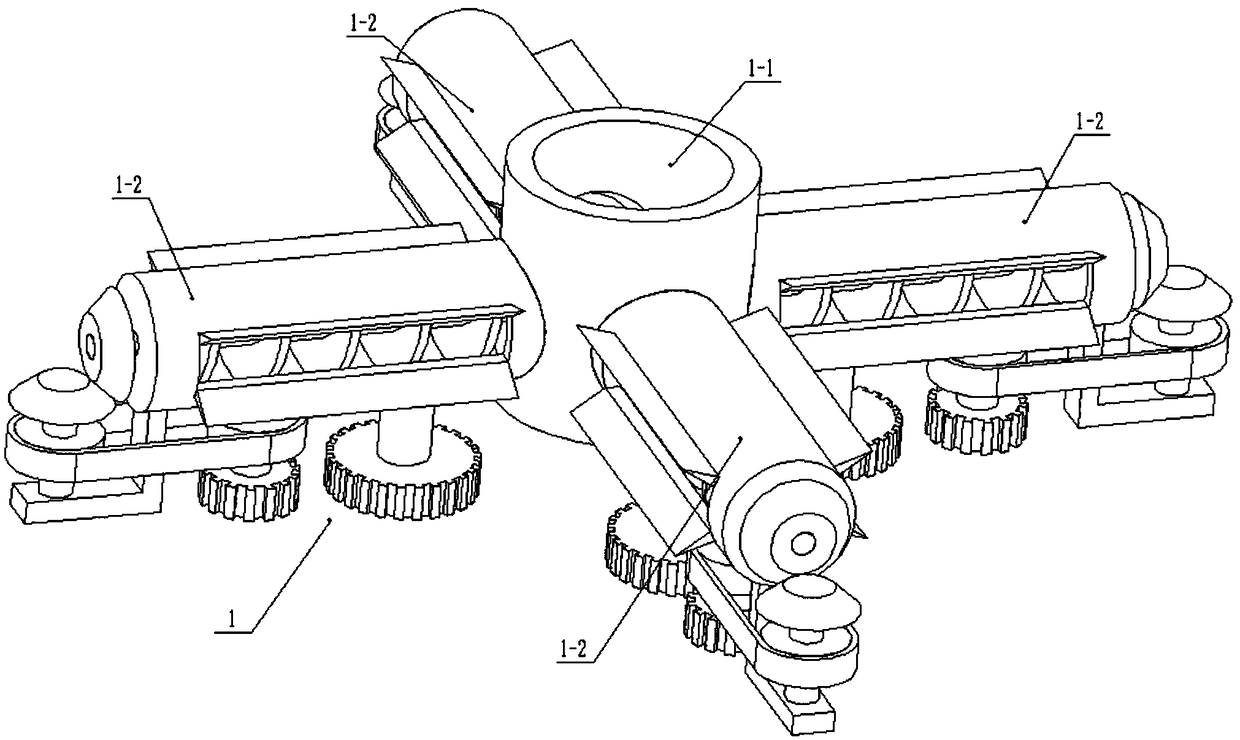

[0031] Combine below Figure 1-9 To illustrate this embodiment, the garbage suction piece 1-2 includes a suction cylinder 1-2-1, a blade shaft 1-2-2, a rotating transmission blade 1-2-3, a transmission bevel gear 1-2-4, a drive Bevel gear 1-2-5, short shaft Ⅰ 1-2-6, driving pulley 1-2-7, short shaft frame 1-2-8, driving pulley 1-2-9, short shaft Ⅱ 1-2-10, Drive gear 1-2-11, planetary wheel shaft 1-2-12, planetary wheel 1-2-13 and garbage feed port 1-2-14; suction cylinder 1-2-1 is fixedly connected to garbage flow through cylinder 1- 1, the suction cylinder 1-2-1 communicates with the interior of the garbage flow through cylinder 1-1, and the middle end of the blade rotating shaft 1-2-2 is rotatably connected to the outer end surface of the suction cylinder 1-2-1 through a bearing with seat , the spiral transmission blade 1-2-3 and the transmission bevel gear 1-2-4 are respectively fixedly connected to the two ends of the blade rotating shaft 1-2-2, and the spiral transmissio...

specific Embodiment approach 3

[0032] Combine below Figure 1-9 To illustrate this embodiment, the garbage suction part 1-2 also includes a deflector swash plate 1-2-15; the upper and lower ends of the garbage inlet 1-2-14 are respectively fixedly connected with a deflector swash plate 1-2 -15, the angle between the two sloping plates 1-2-15 is 120 degrees, and a diversion opening is formed between the two sloping plates 1-2-15, which can make the ship move more The marine garbage is introduced into 1-1 pieces of garbage flow-through barrels, which improves the efficiency of marine garbage removal, reduces labor intensity of workers, improves cleaning efficiency, and is practical and environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com