Positioning support rod with same joint and support structure thereof

A technology for positioning support rods and supporting structures, which is applied to building construction, on-site preparation of building components, formwork/formwork/working frames, etc., can solve problems such as low construction efficiency, high cost, and complex structure, and achieve Convenience and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

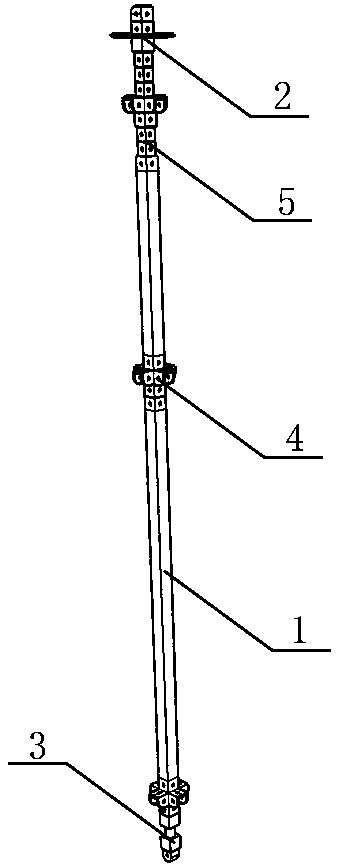

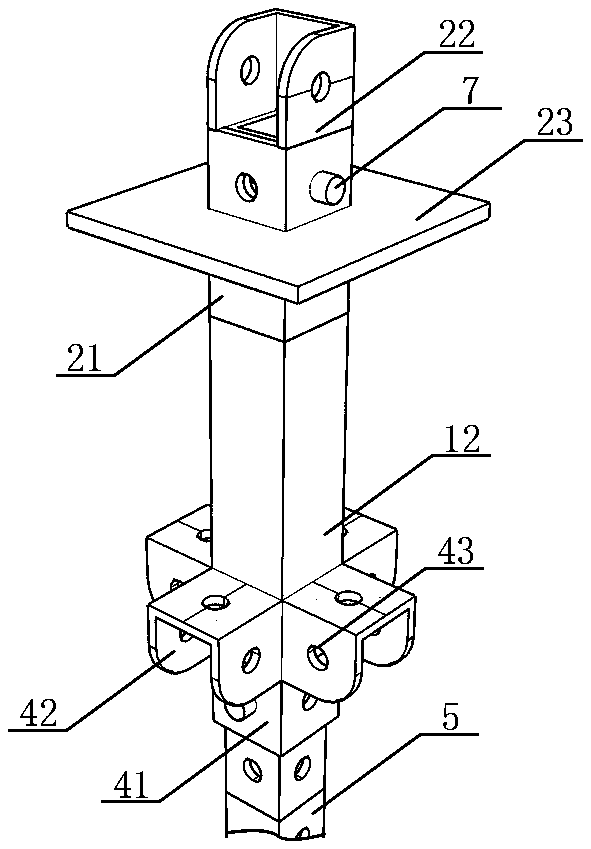

[0035] Examples see figure 1 As shown in the same-section positioning support rod, the main body of the support rod 1 is a standpipe; the upper end of the standpipe has a positioning joint 2, and the lower end has a positioning head 3, forming an upper and lower same-section positioning support rod. The standpipe includes at least one square pipe segment, and adjacent segments are connected by pin tubes; both ends of the pin tubes are correspondingly inserted into the segments and connected by pin shafts.

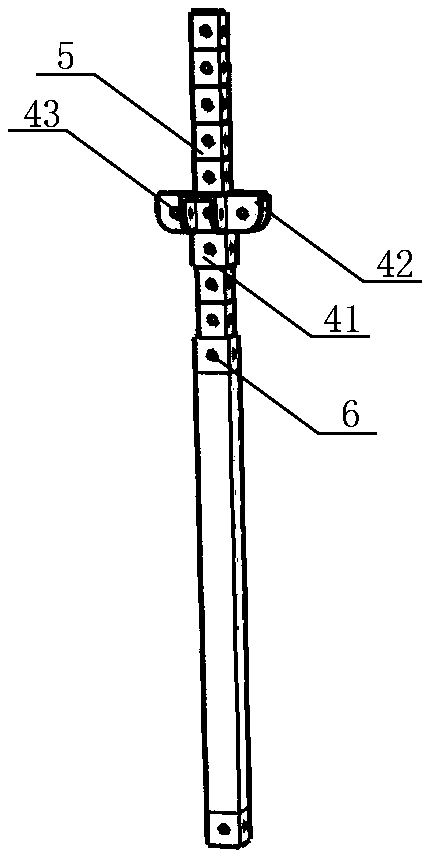

[0036] see figure 2 As shown, the standpipe is made of a square tube, and at least one pair of opposite side walls at both ends of the square tube has pin holes 6; The pin shaft 7 is fixed to form a sleeved connection; the standpipe and the pin tube form a combined pipe that is sleeved and connected to each other;

[0037] The pin tube is a square tube with an outer diameter corresponding to the inner diameter of the standpipe, with pin holes 6 on at least one pair of op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com