Open cut tunnel and tunnel bottom pile raft structure passing through half-filled karst cave

A slab structure and karst cave technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as the impossibility of fully revealing karst caves, and achieve the effects of ensuring tunnel construction and operation safety, saving engineering investment, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

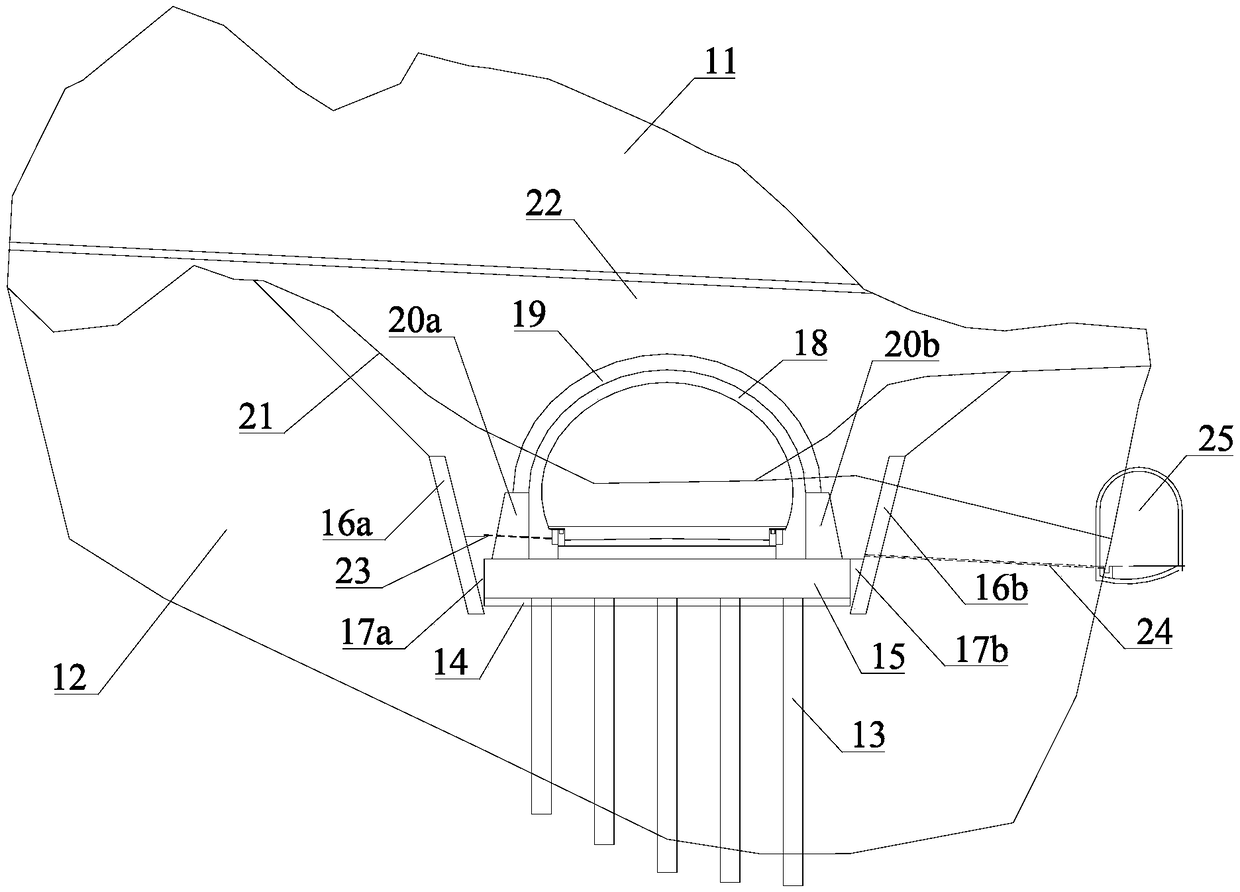

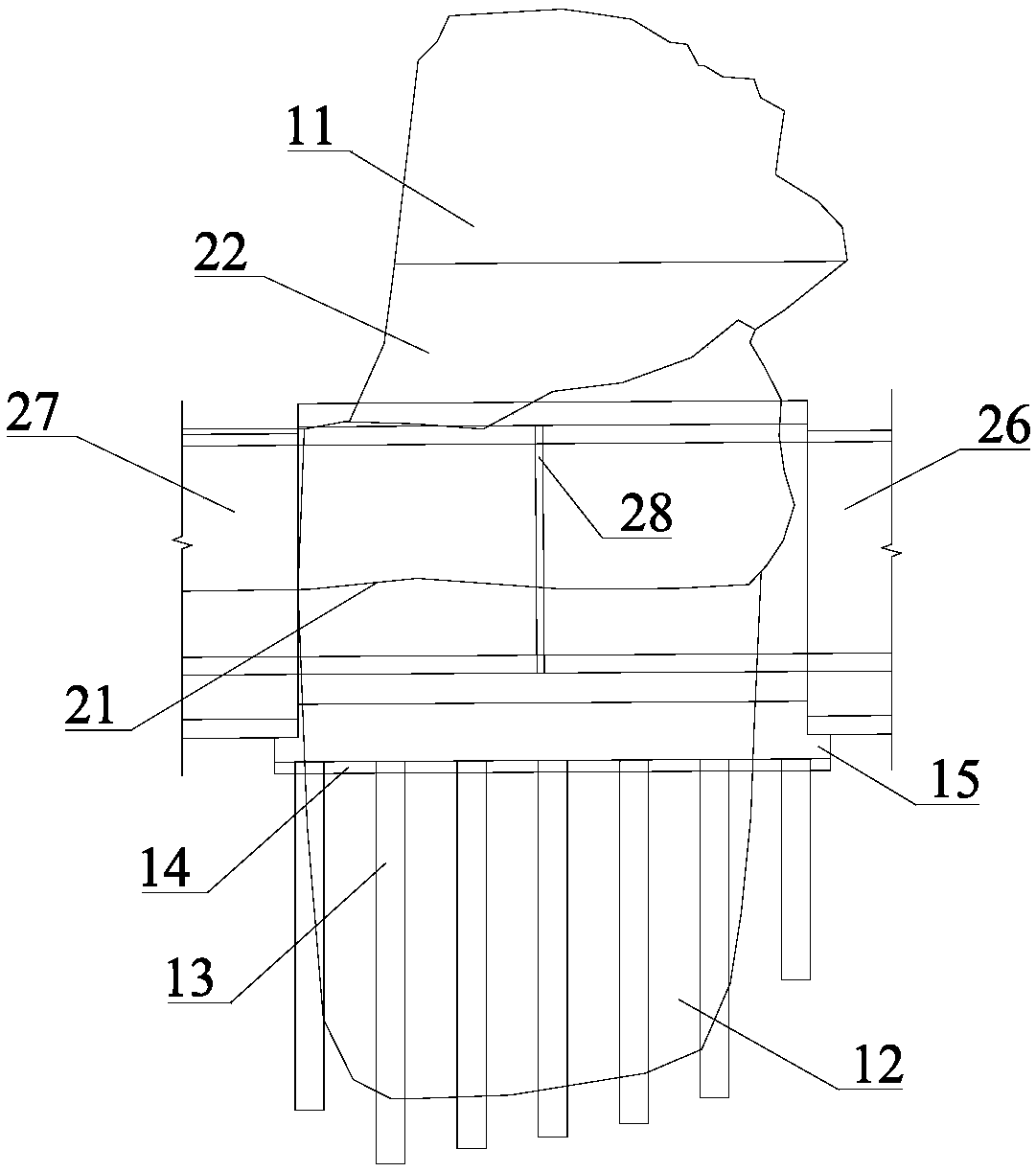

[0032] Such as Figure 1-Figure 2 As shown, the large semi-filled cave includes an upper empty cave 11 and a lower filled cave 12, and there is a boundary line 21 between the empty cave and the filled cave. When the tunnel passes through a large semi-filled karst cave, the present invention provides an open cave and tunnel bottom pile raft structure passing through the semi-filled karst cave. And the raft 15, and the open hole 18 and the guard arch 19 for passing through the upper empty karst cave 11, the open hole 18 and the guard arch 19 are located on the raft 15. A left retaining wall 16a and a right retaining wall 16b are respectively arranged on both sides of the pile foundation and the retaining arch 19 to form a stable construction space for the tunnel bottom structure and the open tunnel structure.

[0033] When the pile foundation 13 passes through the lower filling karst cave 12, the depth of embedding in the bedrock at the bottom is greater than or equal to 2m. Ac...

Embodiment 2

[0038] A construction method for an open cave and tunnel bottom pile raft structure passing through a semi-filled karst cave, comprising the following steps:

[0039] Step 1: Determine the scope of the open hole 18 and the pile foundation 13, and construct the left retaining wall 16a and the right retaining wall 16b. make space;

[0040] Step 2: Construct the pile foundation 13 for passing through the lower filled karst cave 12, wherein the pile foundation 13 is embedded in the bedrock at the bottom to a depth greater than or equal to 2m, and the pile foundation 13 is arranged at intervals horizontally and vertically according to the span of the tunnel and the scope of the karst cave , pile foundation 13 adopts bored pile;

[0041] Step 3: constructing a concrete grout-stopping board 14 on the top of the pile foundation 13, wherein the thickness of the grout-stopping board 14 is greater than or equal to 50 cm;

[0042]Step 4: Construction of the reinforcement of the raft 15,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com