A frequency-adjustable single-stage multi-frequency resonance muffler

An adjustable, multi-frequency technology, applied in the direction of intake mufflers, mufflers, machines/engines, etc., can solve the problems of a single Helmholtz resonator with a narrow muffler frequency band and a limited range of applications, and improve the application Small range, improved noise reduction, and overcome the effect of occupying a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

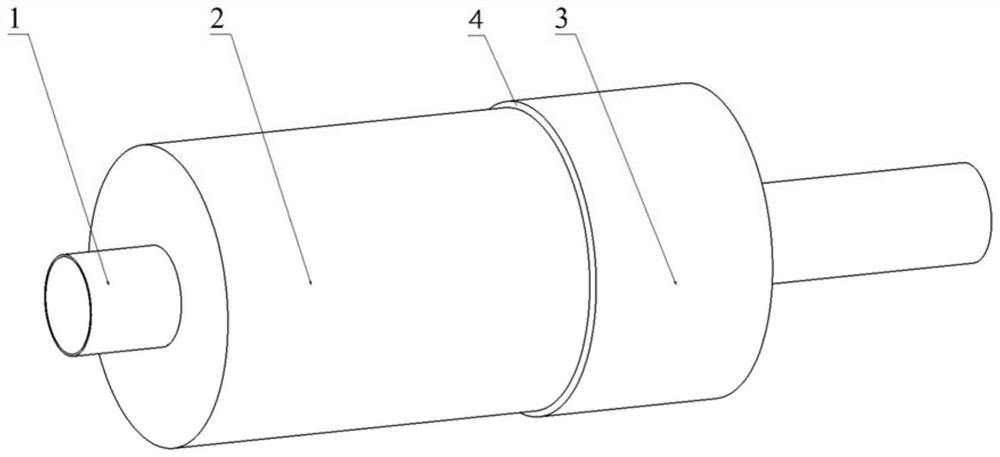

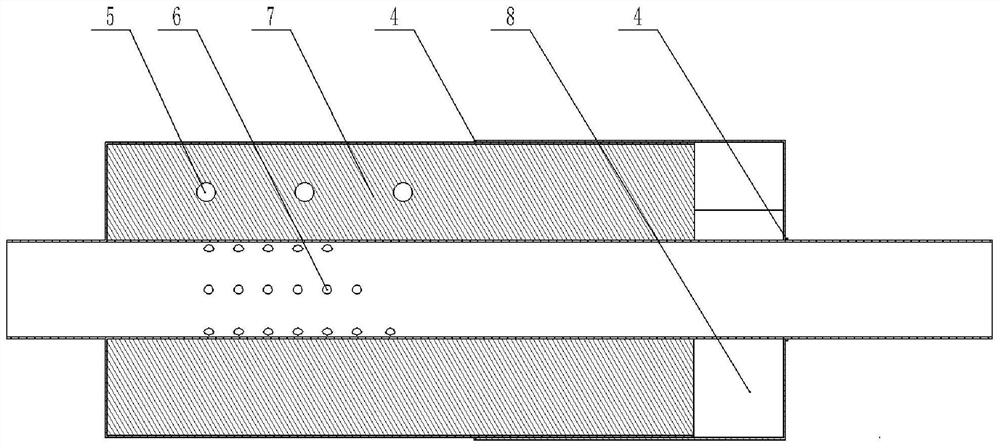

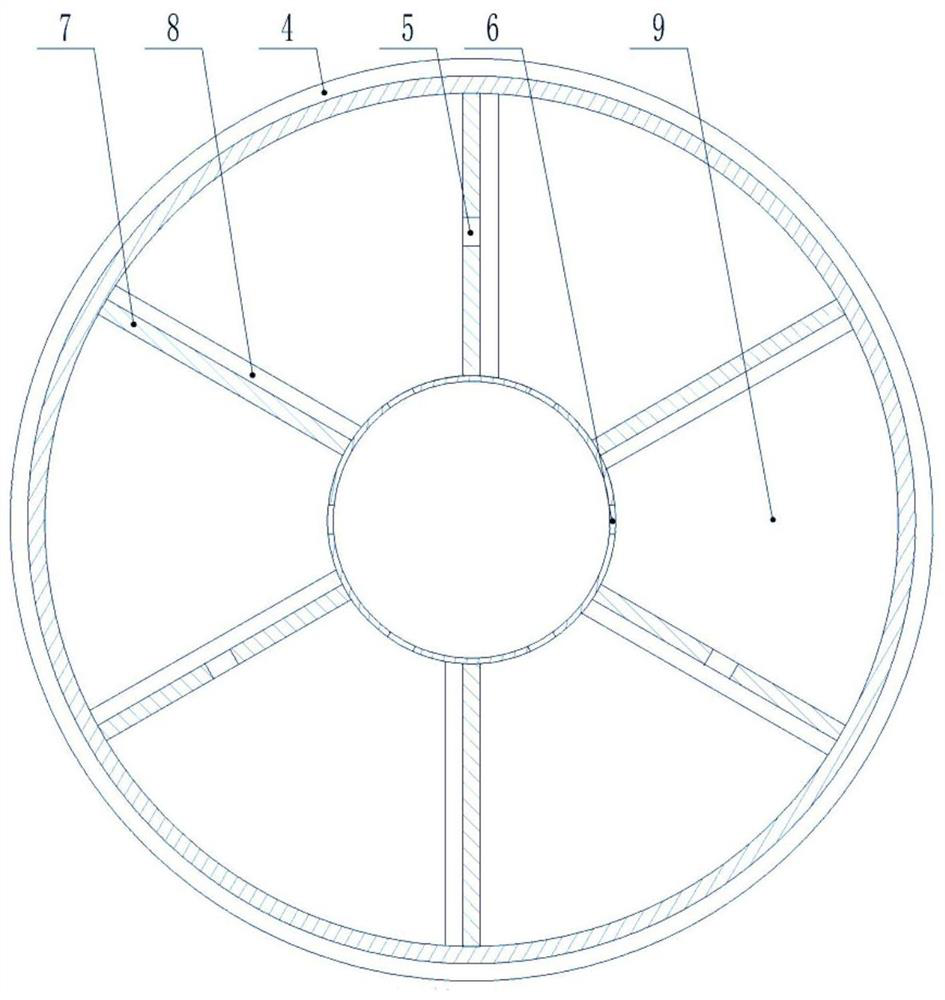

[0031] Such as figure 1 , 2 , 3, a frequency-adjustable single-stage multi-frequency resonance muffler, comprising an exhaust pipe 1, a hollow fixed housing 2 with an end cap on one end, a movable housing 3 hollow and an end cap on one end ( The end cover here adopts sealing ring 4 to ensure the sealing of the resonance cavity), sealing ring 4, fixed board 7 and movable board 8; the outer side of exhaust pipe 1 is covered with fixed housing 2, and the inner diameter of movable housing 3 is slightly Larger than the outer diameter of the fixed shell 2, the open end of the movable shell 3 is overlaid on the open end of the fixed shell 2. After the fixed shell 2 and the movable shell 3 are socketed, the sealing ring 4 is used to seal, and the movable The other end of the casing 3 is sleeved on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com