Electronic bulk flow scale

An electronic bulk material and flow scale technology, which is applied in the field of grain processing, can solve the problems of high impact force of flow scale, damage of flow scale, food waste, etc., and achieve the effects of good stability, reduced passing rate and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

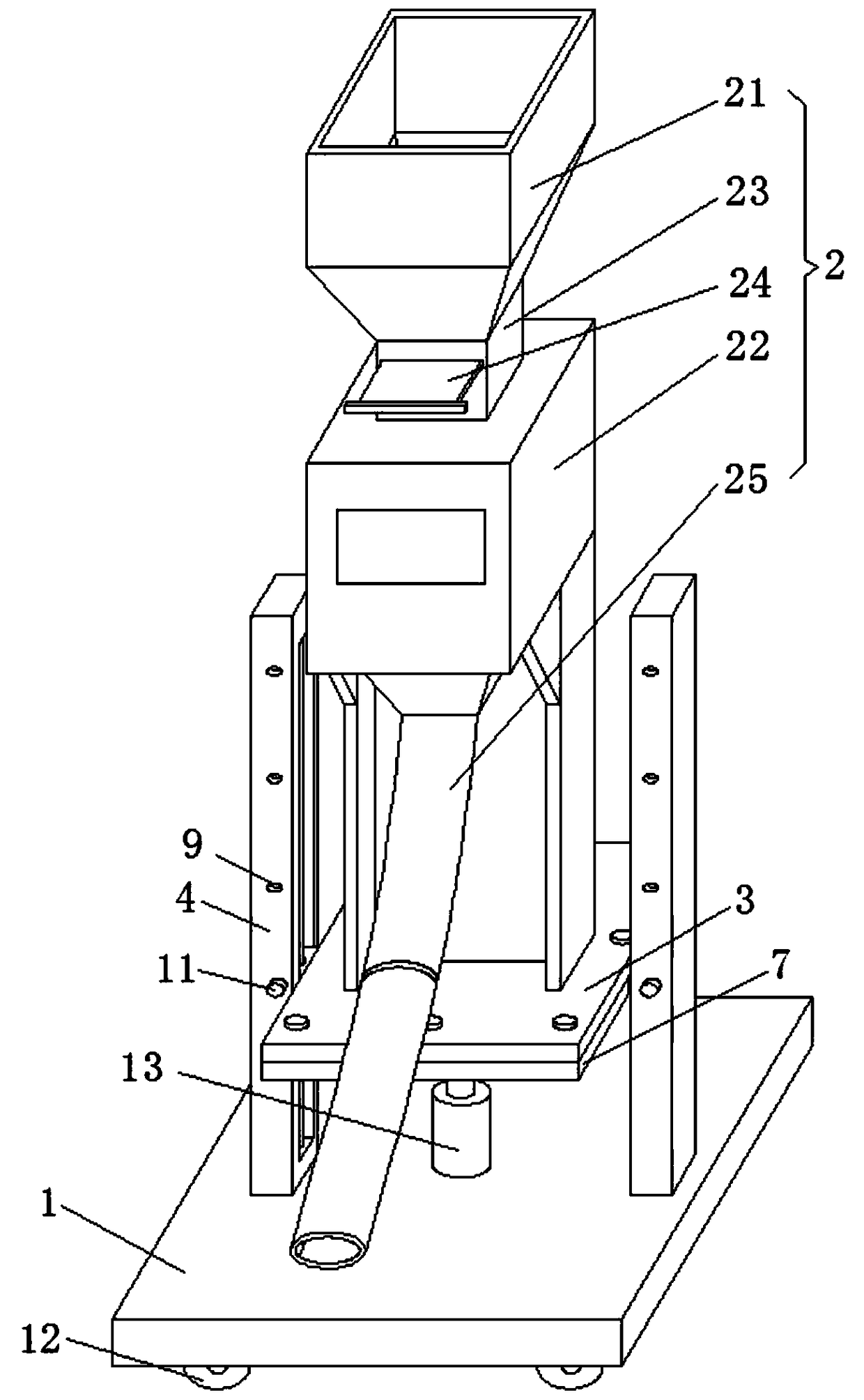

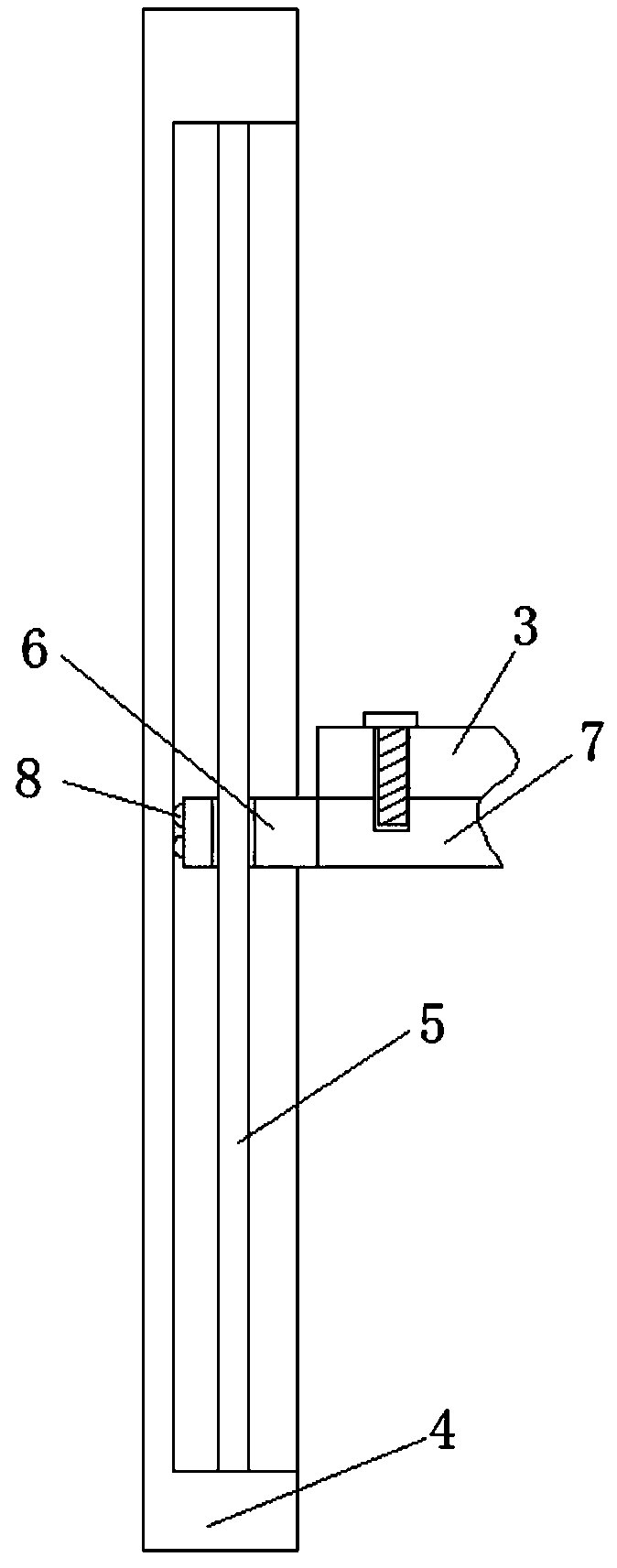

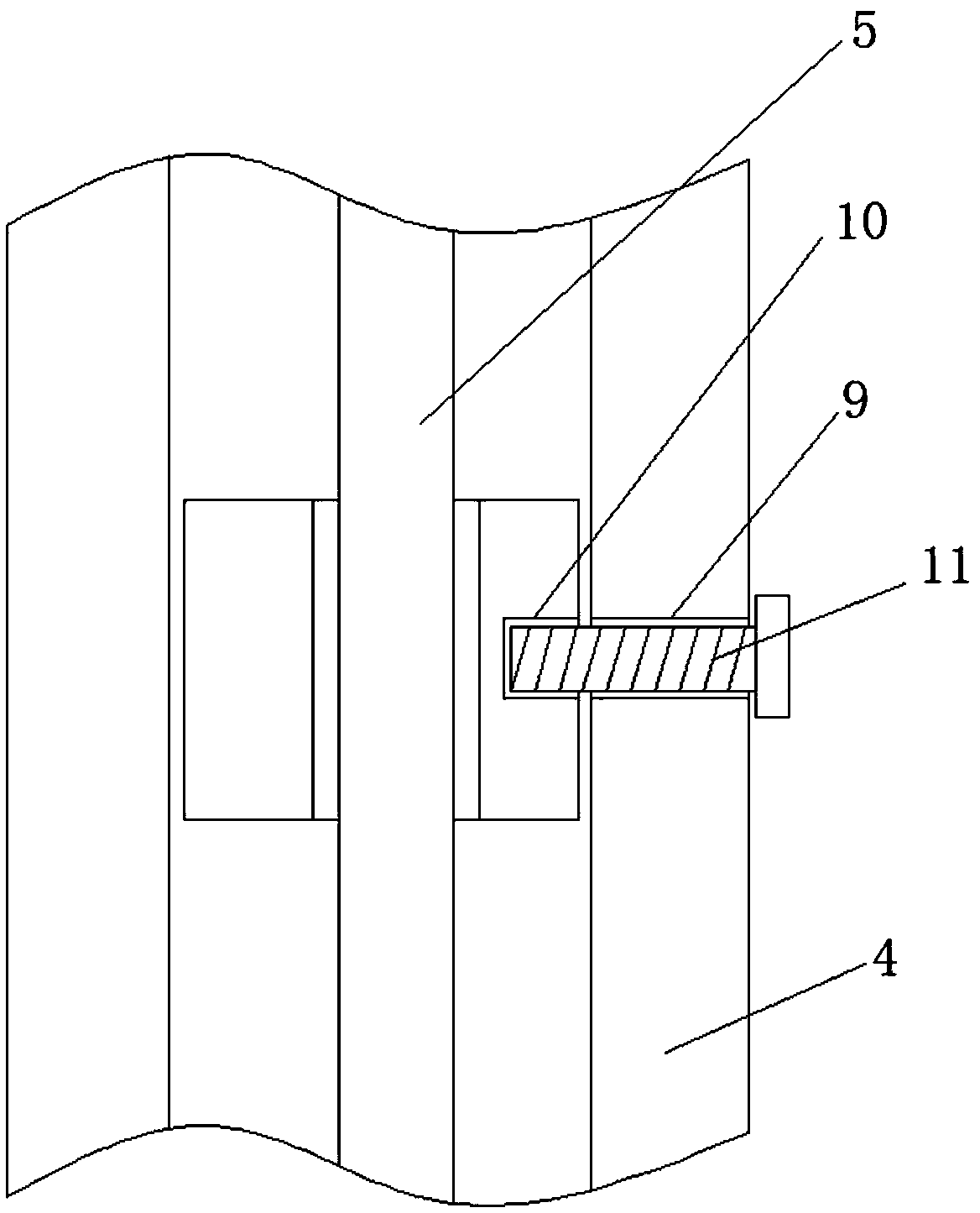

[0019] see Figure 1-3 , this embodiment provides an electronic bulk material flow scale, including a bottom plate 1 and a flow scale body 2, the bottom of the flow scale body 2 is fixedly connected with a fixed steel plate 3, and the top of the bottom plate 1 is fixedly connected with a limit rail 4, and the limit rail The inner wall of 4 is fixedly connected with the limit shaft 5, the surface of the limit shaft 5 is sleeved with a sliding block 6, one side of the sliding block 6 is welded with a fixed plate 7, the fixed plate 7 is movably connected with the fixed steel plate 3, and the top of the bottom plate 1 is fixed A hydraulic cylinder 13 is installed, the model of the preferred hydraulic cylinder 13 is SFY-001, the hydraulic cylinder 13 is fixedly connected with the fixed plate 7, the front of the limit rail 4 is provided with a locking hole 9, and the front of the sliding block 6 is provided with a lock The locking groove 10 and the inner wall of the locking hole 9 a...

Embodiment 2

[0022] see Figure 1-3 , On the basis of Embodiment 1, a further improvement has been made: the flow scale body 2 includes a collecting hopper 21 and a weighing cylinder 22, and a feeding passage 23 is arranged between the collecting hopper 21 and the weighing cylinder 22, and one side of the feeding passage 23 The material baffle plate 24 is plugged in, and the grain flows through the collecting hopper 21 through the material channel 23 and enters the inside of the weighing cylinder 22 for weighing. By pulling the material baffle plate 24, the flow rate of the particles in the material passing channel 23 can be controlled. When the rate is too high, the baffle plate 24 can be properly pushed into the feeding channel 23, thereby reducing the internal outlet of the feeding channel 23, thereby reducing the passing rate of the grain, which facilitates the use of different grains.

[0023] Wherein, the bottom of the base plate 1 is provided with universal wheels 12, and by setting...

Embodiment 3

[0025] see Figure 1-3 , on the basis of Embodiment 1, a further improvement is made: the side of the sliding block 6 away from the fixed plate 7 is provided with a ball 8, the ball 8 is rollingly connected with the inner wall of the limit rail 4, and the ball 8 can further adjust the position of the sliding block 6 Limit, and can make the sliding of slide block 6 smoother, the bottom of weighing cylinder 22 is communicated with discharge pipe 25, and discharge pipe 25 is formed by multi-section pipeline connection, and the length of discharge pipe 25 is determined by the length of pipeline, says The grain after the amount can enter in the loading equipment through the feeding pipe 25, and the phenomenon of grain spraying can not be caused to take place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com