Measuring device and method for three-direction force of knife roller used in rotary tillage soil tank test bench

A measuring device and three-dimensional force technology, which is applied in the direction of measuring device, force/torque/work measuring instrument, instrument, etc. Unfavorable problems such as the analysis of the three-dimensional force of the knife roll, and achieve the effect of simple structure, high reliability, and reduced width accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

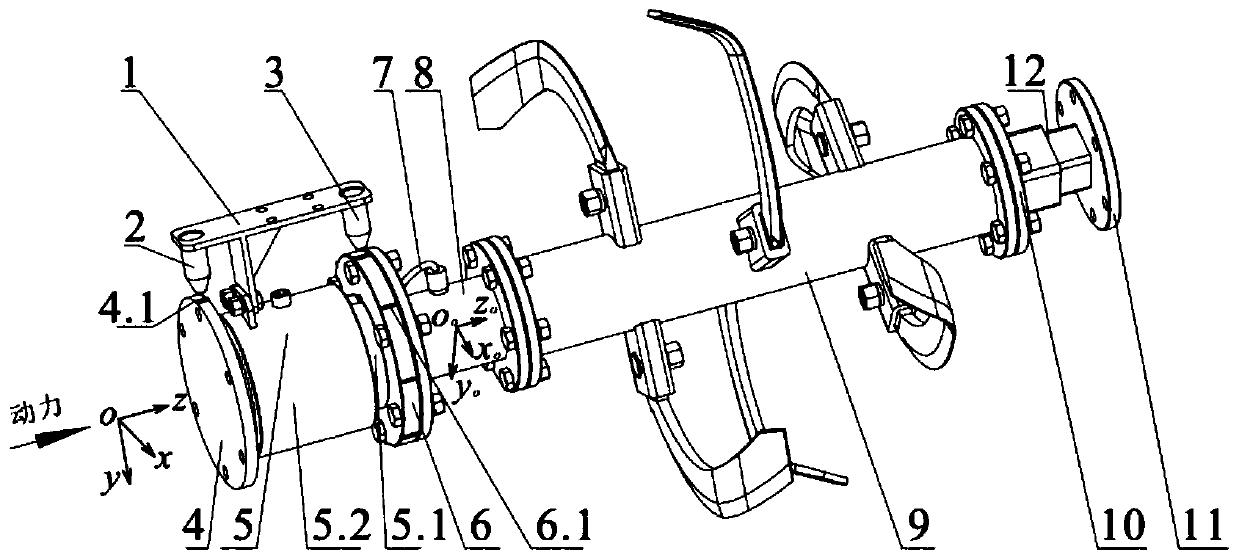

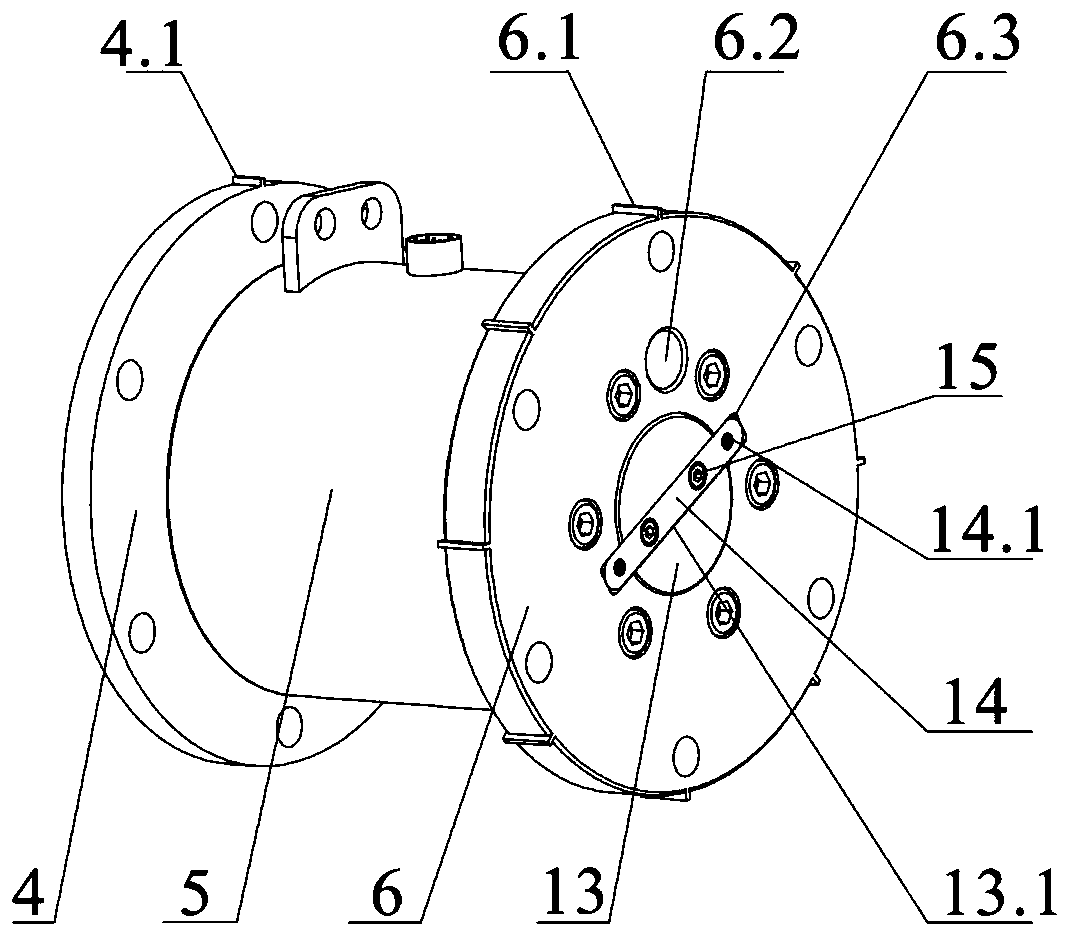

[0037] Below in conjunction with accompanying drawing, measuring device of the present invention is described further:

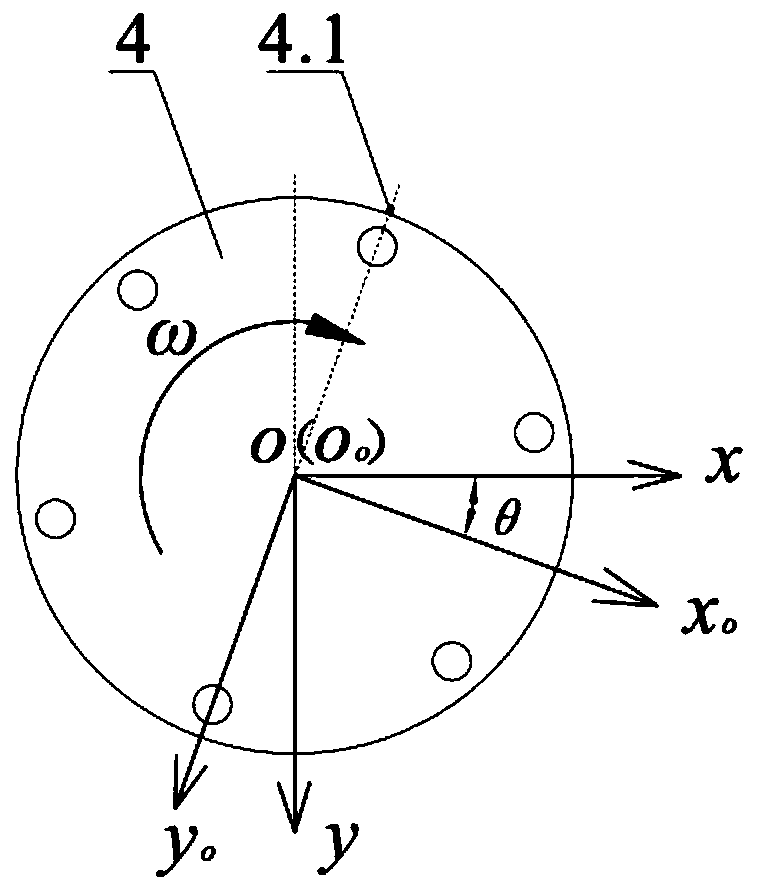

[0038] see figure 1 , the measuring device of the present invention comprises a three-way force sensor 8 whose rear end can be connected with one end of the knife roller 9, and the front end of the three-way force sensor 8 is connected with an indexing disk 6, and the indexing disk 6 is connected to the initial stage via a transmission shaft 13. The transmission shaft 13 is equipped with a conductive slip ring 5. The structural principle of the conductive slip ring 5 is the prior art, mainly including the rotor 5.1 of the inner ring and the stator 5.2 of the outer ring. The brush structure of the ring connects the rotor 5.1 with the stator 5.2, the rear end of the rotor 5.1 is connected with the index disc 6 by bolts, the width of the rotor 5.1 is larger than that of the stator 5.2, and the gap between the rotor 5.1 and the transmission shaft 13 Cooperate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com