Multi-cavity overlaying type non-resonant photoacoustic cell and gas detection system

A non-resonant, superimposed technology, used in the field of high-sensitivity gas detection systems, can solve problems such as low sensitivity, and achieve the effect of improving strength and easy matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

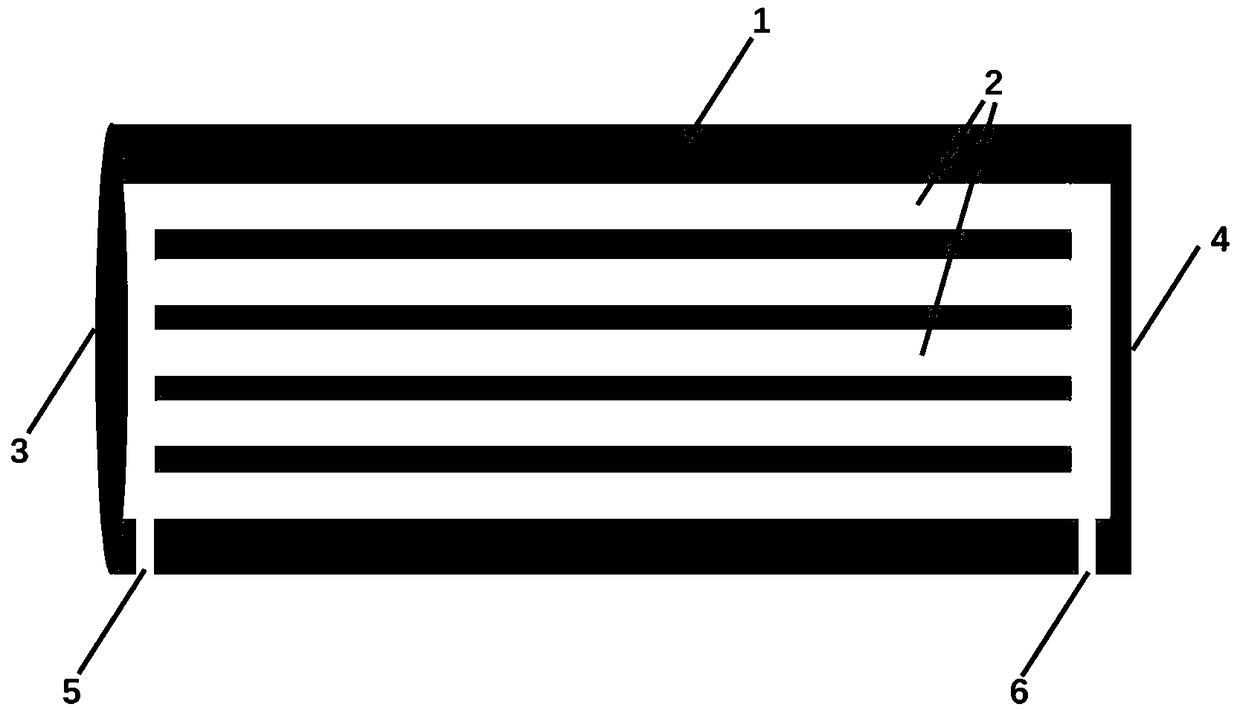

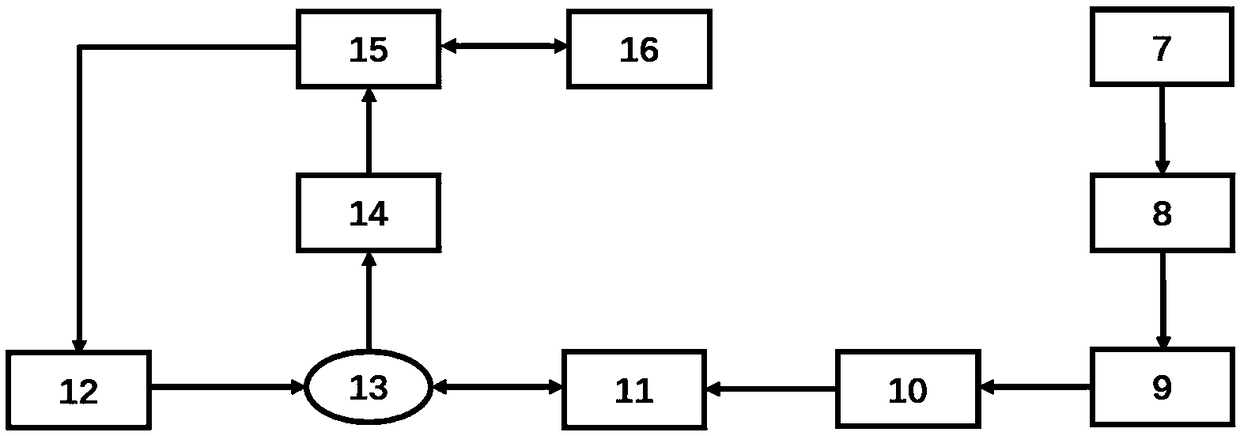

[0014] The present invention provides such as figure 1 The multi-cavity superimposed non-resonant photoacoustic cell shown is mainly composed of a cylindrical metal shell 1, a plurality of non-resonant photoacoustic cavities 2, a sensitive diaphragm 3 of an optical fiber Fabry-Perot acoustic wave sensor, an optical glass window 4, Air inlet 5 and outlet hole 6 are formed. The sensitive diaphragm 3 of the optical fiber Fabry-Perot acoustic wave sensor is fixed on one end of the multi-cavity superimposed non-resonant photoacoustic cell, and the photoacoustic signals generated in the multiple non-resonant photoacoustic cavities 2 are transmitted through the optical fiber Fabry-Perot acoustic wave. Superimposition occurs at the sensitive diaphragm 3 of the sensor, which causes the periodic vibration of the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com