Rapid machining method for non-curved parts

A processing method and technology for curved parts, which are applied in the directions of instruments, computer control, simulators, etc., can solve the problems of low processing efficiency of non-curved parts, and achieve the effect of improving processing efficiency and programming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

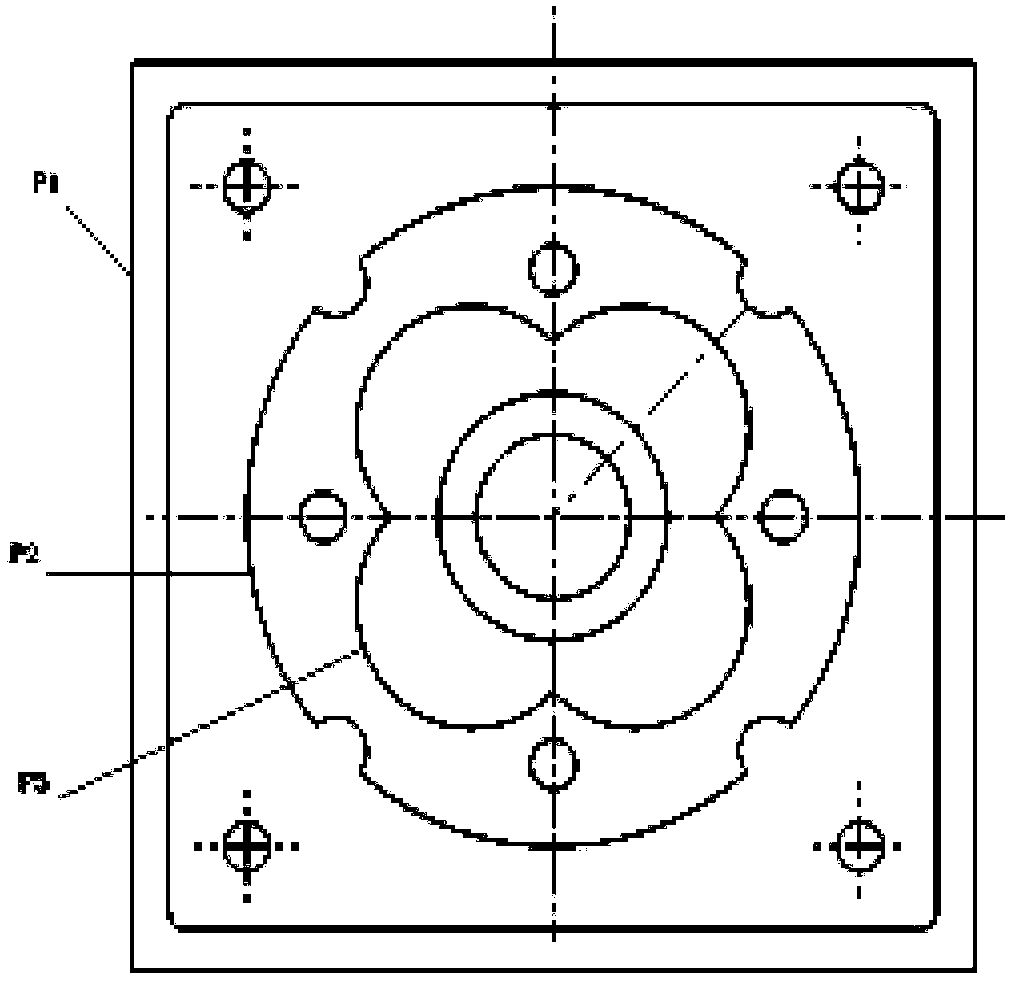

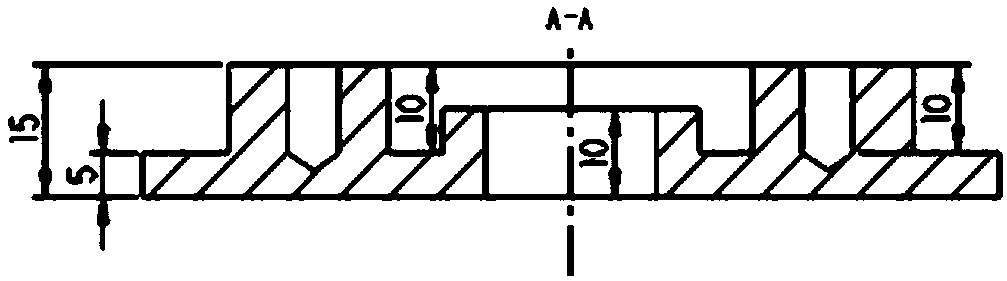

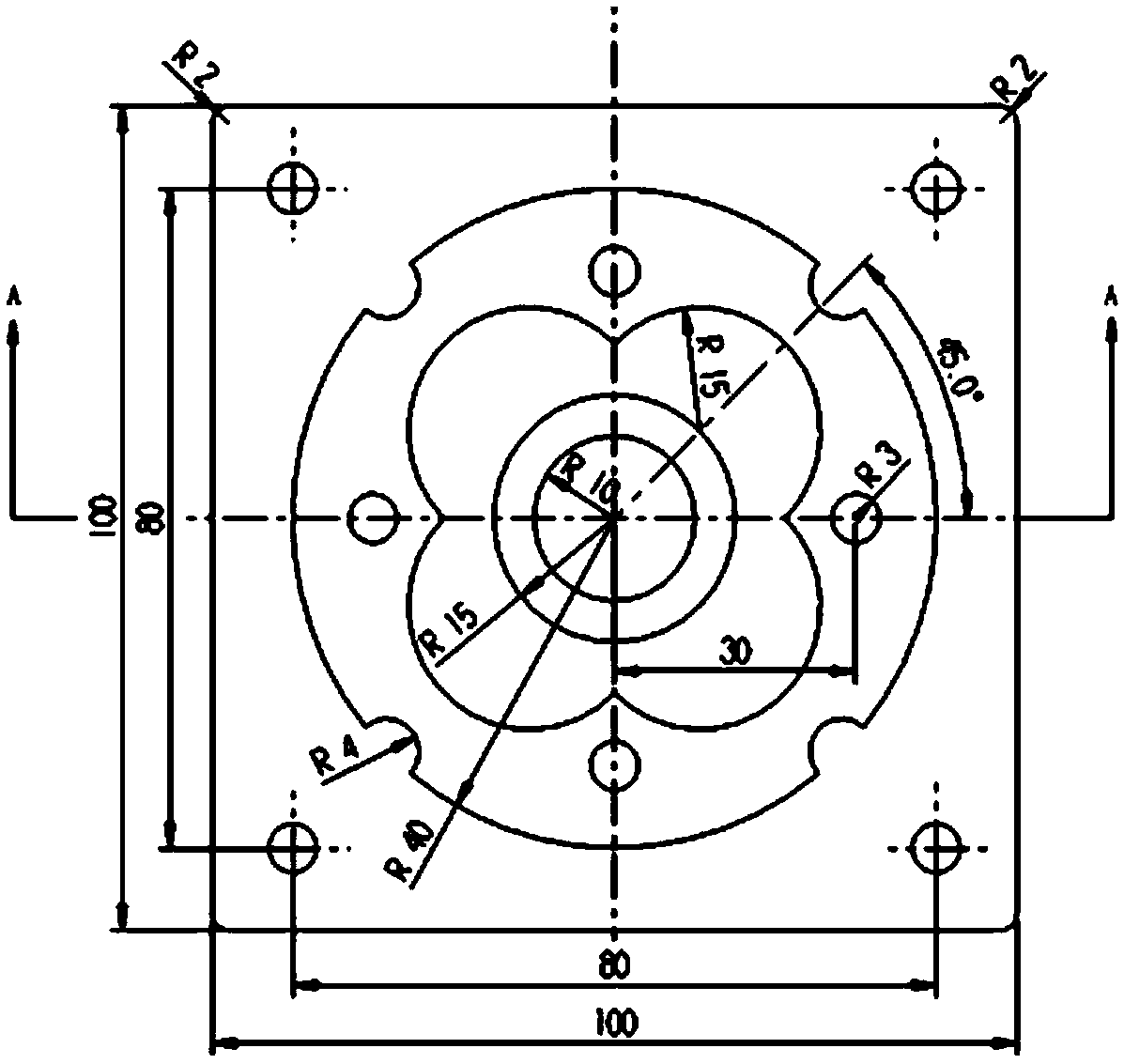

[0035] The two-dimensional modeling diagram of the processed part is as follows figure 1 as shown, Figure 2a It is a front view of a rapid processing method for non-curved surface parts of the present invention; Figure 2b It is a top view in the rapid processing method of a non-curved surface part of the present invention; it can be seen that the part includes a bottom surface, a top plane, an outline, an inner hole, a drill hole, etc., and the blank size is 110mmX110mmX25mm, and the material is cast aluminum.

[0036] Establishing the model of the part according to the design requirements is the basis for the realization of NC machining. Whether the model of the part can be established correctly has become the key to the smooth progress of CAM. Since the part model only has simple shapes such as planes and holes, and does not have comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com