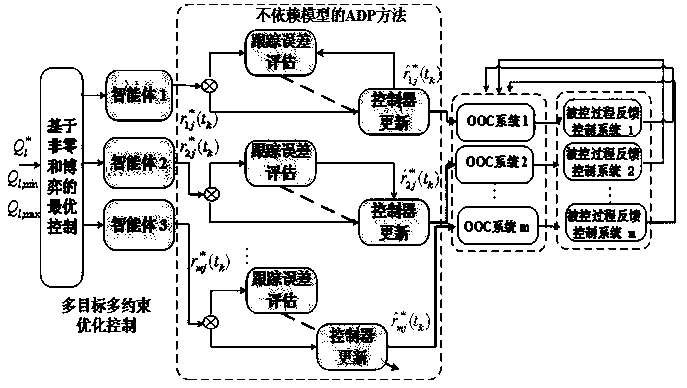

Complex industrial process data-driven whole plant level performance optimization control method

An optimization control and industrial process technology, applied in the direction of comprehensive factory control, program control, electrical program control, etc., can solve problems such as inaccurate modeling, complexity, multiple production indicators, and multi-unit process coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with examples.

[0039] The implementation process of the present invention is as follows:

[0040] 1. Multi-objective and multi-constraint plant-wide performance optimization control

[0041] The present invention adopts the construction of multi-objective and multi-constraint optimal performance optimization control, including: a) construction of an objective function, to realize that the production index of the whole plant tracks the ideal value in an approximately optimal manner, and the objective function is composed of the tracking error and the running index. subtype composition. At this stage, the scientific problem to be solved is described as the optimal tracking problem at different time scales. The change of operating index is a fast process, while the change of production index is a slow process; b) the description of constraints is based on the dynamics of production index, limited pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com