A method of dispatching workers for a testing machine

A machine and inspection station technology, applied in the field of defect inspection, can solve the problems of waiting for batch inspection, high risk of process machine monitoring, and centralized arrival of batches to the inspection station, etc., to achieve the effect of reducing monitoring risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

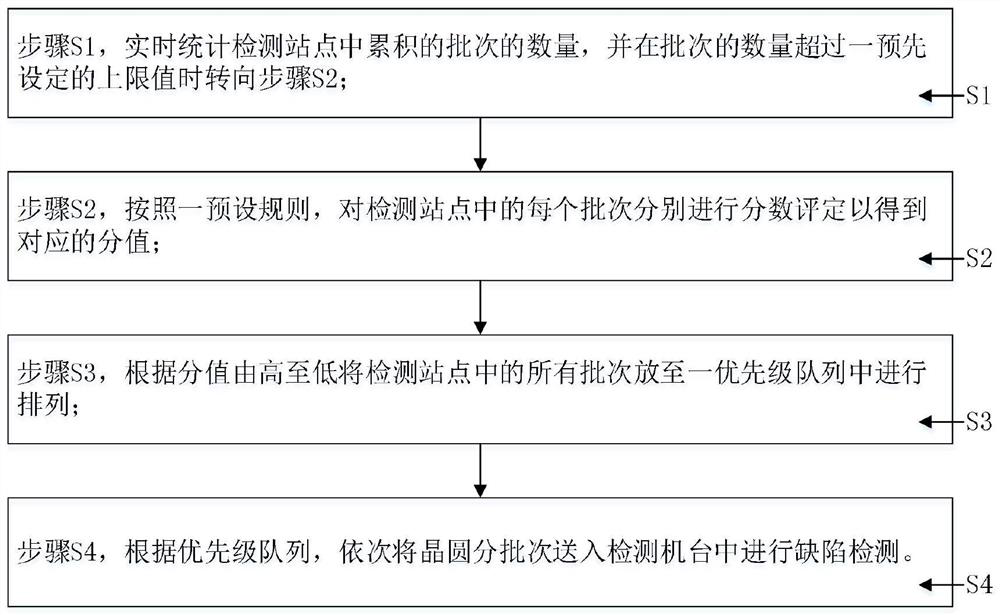

[0028] In a preferred embodiment of the present invention, based on the above-mentioned problems in the prior art, a dispatching method for inspection machines is now provided, in which the wafers waiting for inspection are sent to the inspection site in batches according to the order of dispatching In the waiting queue, and according to the waiting queue, the wafers are sequentially sent to the inspection machine in batches for defect detection, such as figure 1 shown, also includes:

[0029] Step S1, counting the number of batches accumulated in the detection site in real time, and turning to step S2 when the number of batches exceeds a preset uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com