Chemical waste gas treatment system

A technology for waste gas treatment and chemical industry, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc. It can solve the problems of serious environmental pollution, complex physical and chemical properties, incomplete spraying, etc., and achieve high practical performance and convenient use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

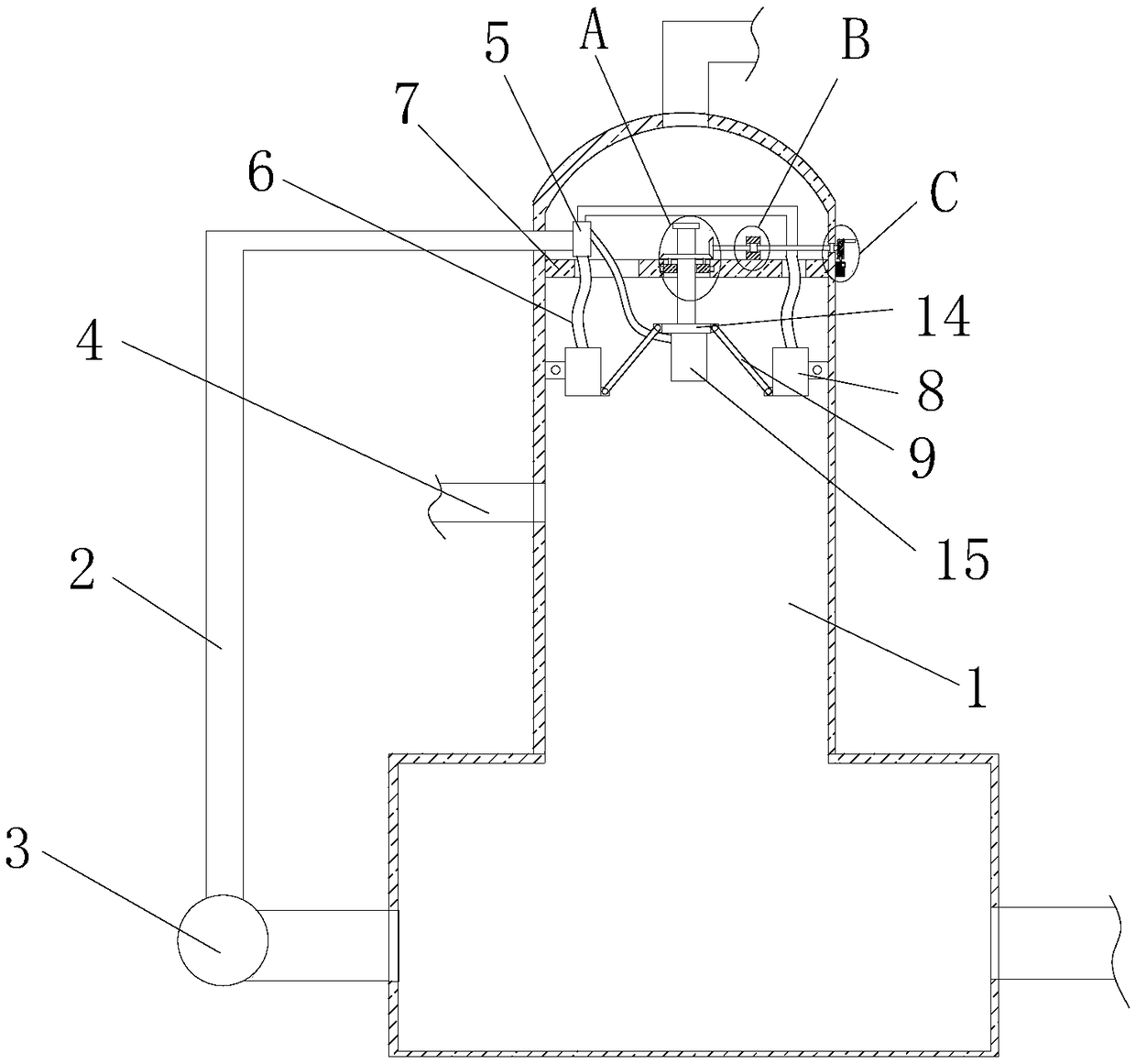

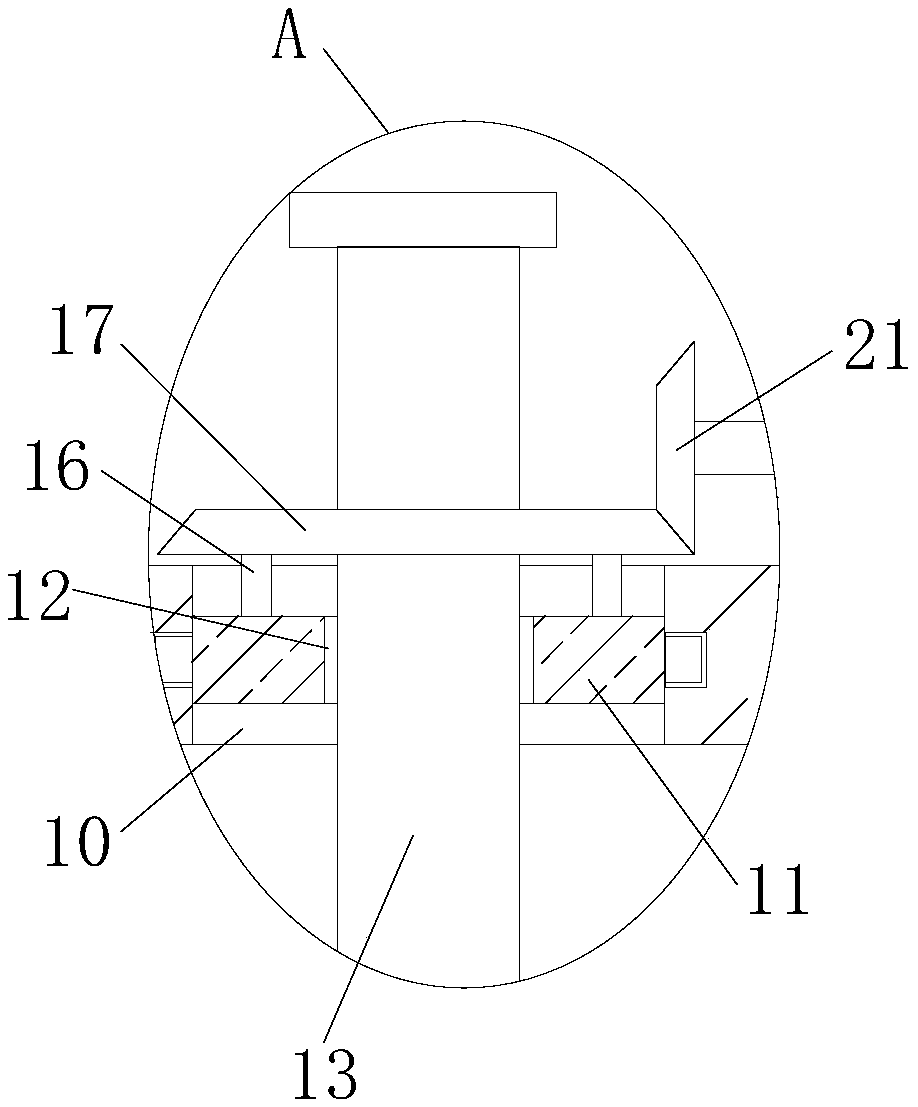

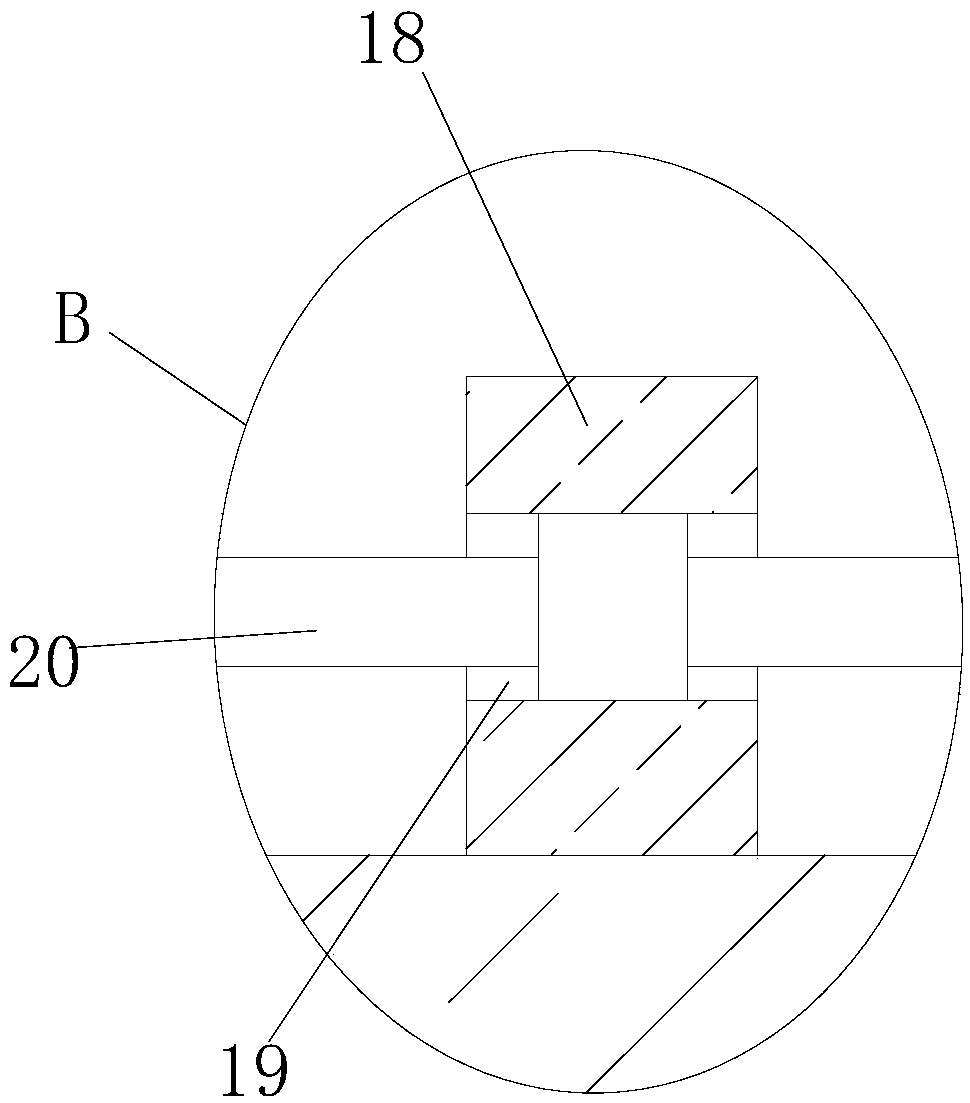

[0027] refer to Figure 1-5In this embodiment, a chemical waste gas treatment system is proposed, including a spray kettle 1, one end of a circulation pipeline 2 is provided on one side of the spray kettle 1, and the other end of the circulation pipeline 2 extends into the spray kettle 1 and A three-way valve 5 is fixedly installed, and one end of the hose 6 is fixedly installed on the three water outlets of the three-way valve 5, a water pump 3 is installed on the circulation pipeline 2, and the same first A plate 7, the first spray head 8 is installed on both sides of the spray tank 1, and the other ends of the two hoses 6 in the three hoses 6 are fixedly connected with the corresponding first spray head 8, The sides of the two first spray heads 8 close to each other are hinged with one end of the adjusting rod 9, and the first plate 7 is provided with a first hole 10, and a rotating rod seat 11 is installed in the first hole 10, and the rotating rod seat 11 is threadedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com