Glutinous rice hulling device

A technology of glutinous rice and chaff, applied in grain hulling, grain processing, application, etc., can solve the problems of not being able to buffer and discharge rice cores, broken rice, and inability to remove iron filings from glutinous rice, so as to avoid excessive impact force and control the removal of iron chips. Shell volume, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

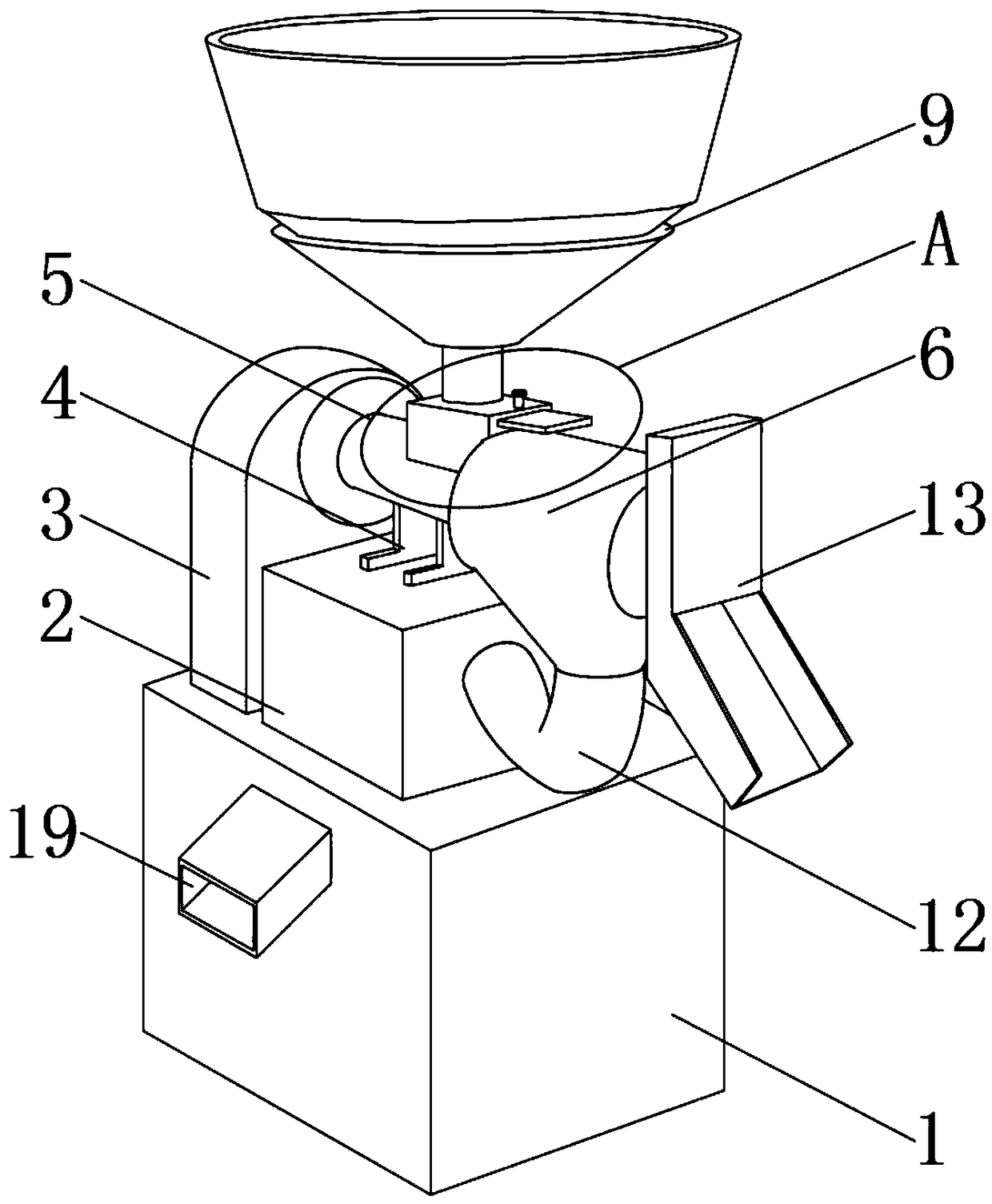

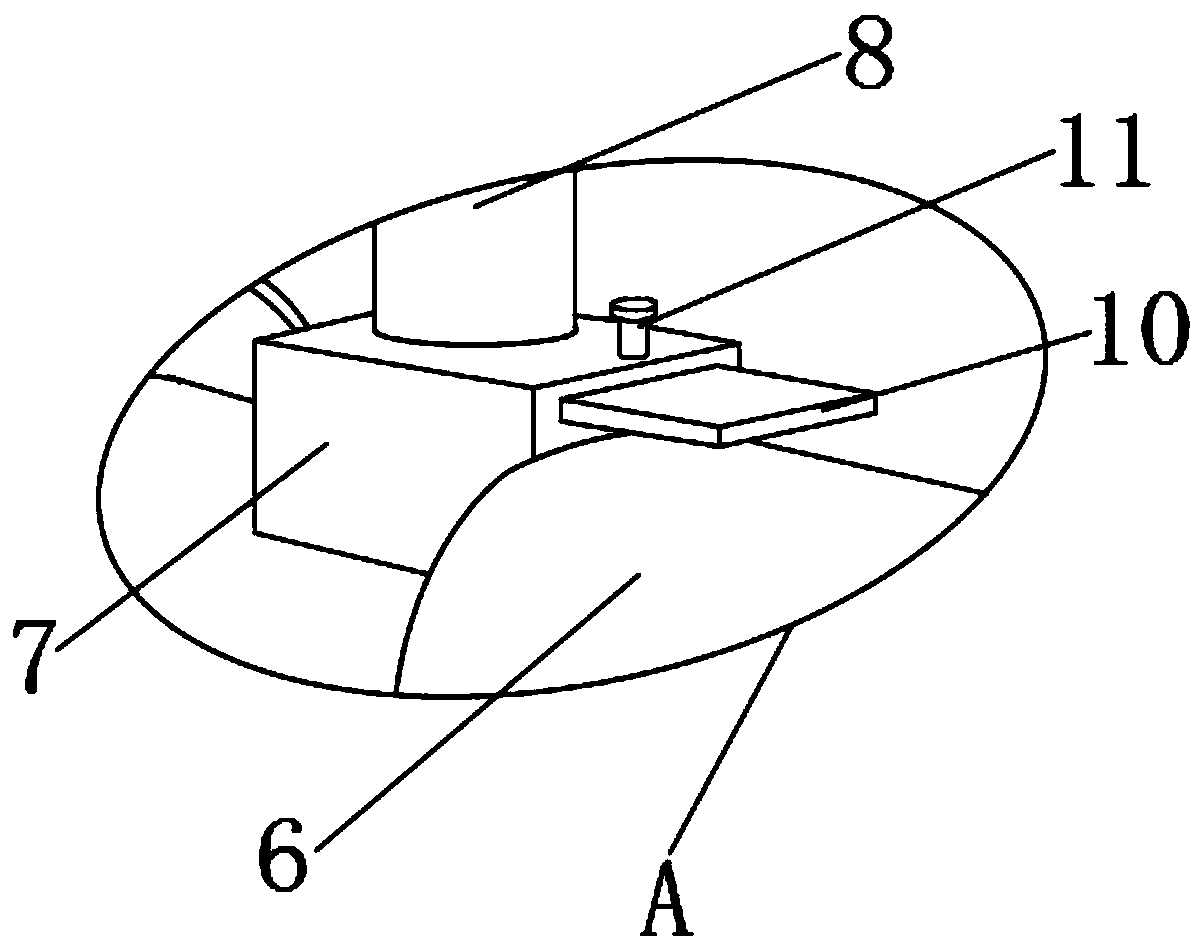

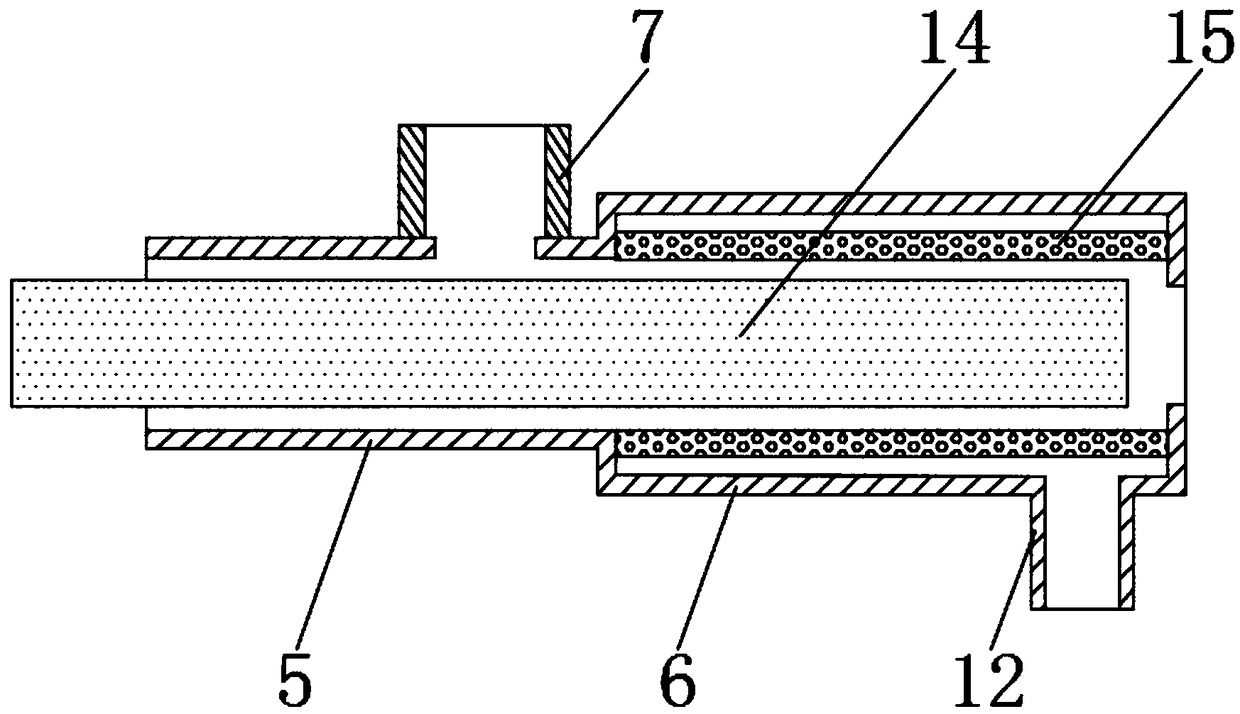

[0026] Such as Figure 1-5 Shown, a kind of glutinous rice hulling device, comprises cabinet 1 and blast box 2, and blast box 2 is fixedly installed on the upper end of cabinet 1, and the upper end side of cabinet 1 is fixedly installed with pulley cover 3, and pulley cover 3 is positioned at the bottom of cabinet 1 On one side, the upper end of the blower box 2 is fixedly installed with a bracket 4, and the upper end of the bracket 4 is fixedly installed with a feed bin 5, and the upper end of the feed bin 5 is connected to a feed box 7, and the upper end of the feed box 7 is connected to a material pipe 8 , the upper end of the material pipe 8 is fixedly installed with a hopper installation sleeve 9, the upper end of the hopper installation sleeve 9 is sleeved with a magnetic feed hopper 16, the lower end of the husking bin 6 is connected with a chaff delivery pipe 12, and the chaff delivery pipe 12 The lower end is communicated with the blower box 2, and the inside of the f...

Embodiment 2

[0028] Such as Figure 1-5 As shown, it includes a chassis 1 and a blower box 2, the blower box 2 is fixedly installed on the upper end of the chassis 1, a pulley cover 3 is fixedly installed on one side of the upper end of the chassis 1, and the pulley cover 3 is located on one side of the chassis 1, and the blower box 2 The upper end of the bracket 4 is fixedly installed with a bracket 4, and the upper end of the bracket 4 is fixedly installed with a feeding bin 5, and the upper end of the feeding bin 5 is connected with a feed box 7, and the upper end of the feed bin 7 is connected with a material tube 8, and the upper end of the material tube 8 is fixed. A hopper installation sleeve 9 is installed, and the upper end of the hopper installation sleeve 9 is sleeved with a magnetic feed hopper 16, and the upper end of the feed box 7 is provided with a baffle 10, and the baffle 10 is located directly below the feed pipe 8, and the feeding The outer surface of the upper end of t...

Embodiment 3

[0030] Such as Figure 1-5 As shown, it includes a chassis 1 and a blower box 2, the blower box 2 is fixedly installed on the upper end of the chassis 1, a pulley cover 3 is fixedly installed on one side of the upper end of the chassis 1, and the pulley cover 3 is located on one side of the chassis 1, and the blower box 2 The upper end of the bracket 4 is fixedly installed with a bracket 4, and the upper end of the bracket 4 is fixedly installed with a feeding bin 5, and the upper end of the feeding bin 5 is connected with a feed box 7, and the upper end of the feed bin 7 is connected with a material tube 8, and the upper end of the material tube 8 is fixed. A hopper installation sleeve 9 is installed, and the upper end of the hopper installation sleeve 9 is sleeved with a magnetic feed hopper 16, and the upper end of the feed box 7 is provided with a baffle 10, and the baffle 10 is located directly below the feed pipe 8, and the feeding The outer surface of the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com