Nut processing system and processing method

A processing system and nut technology, applied in the nut processing system and processing field, can solve the problems of entering the nut shell, inconvenient to open, affecting the eating of nuts, etc., to avoid affecting the eating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

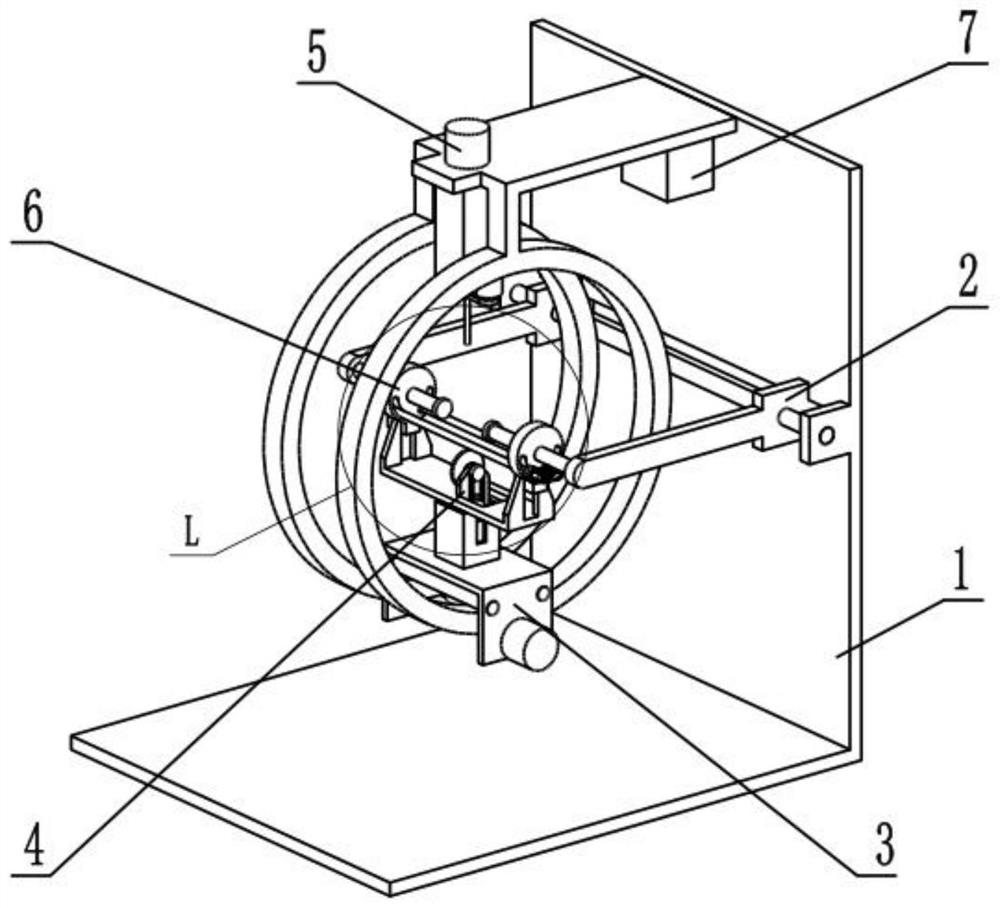

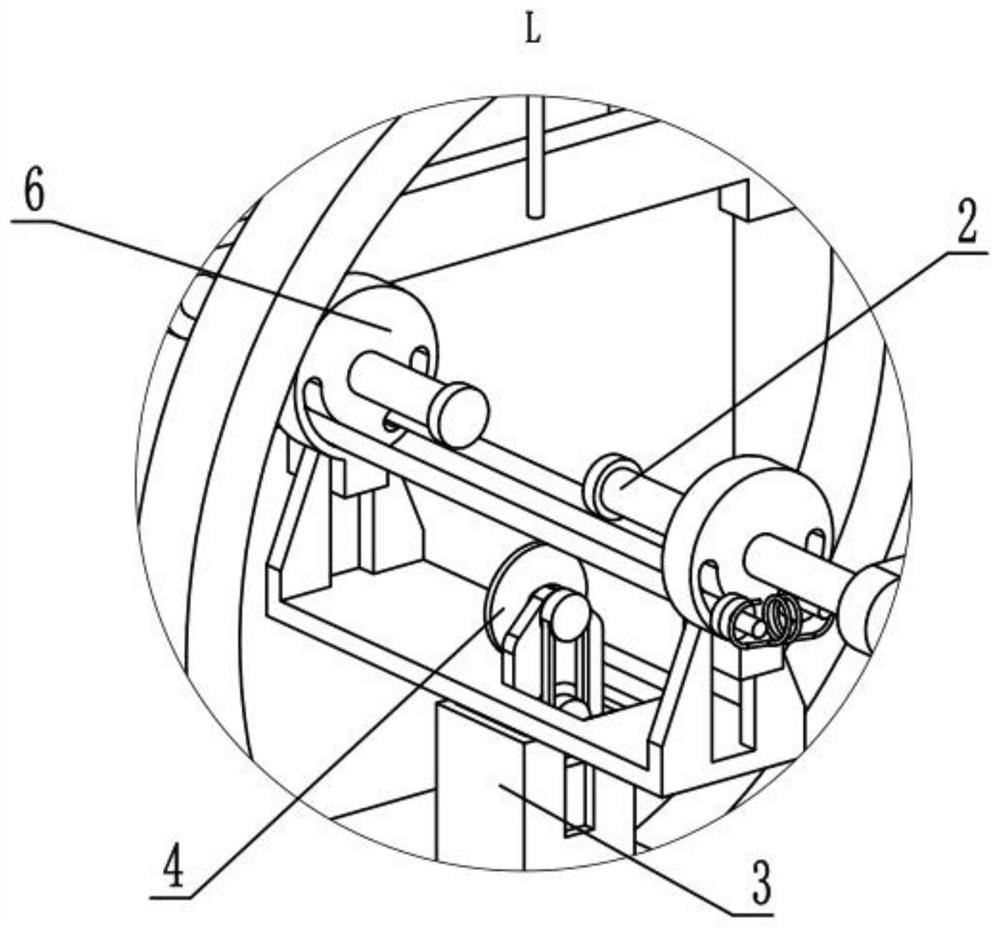

[0031] Such as Figure 1-8 As shown, a nut processing system includes a support frame 1, a clamping mechanism 2, a rotating mechanism 3, a sawing mechanism 4, a drilling blowing mechanism 5, a carrying mechanism 6 and an air pump 7, and the clamping mechanism 2 slides Connected to the support frame 1, the rotating mechanism 3 is rotatably connected to the support frame 1, the saw mechanism 4 is slidably connected to the rotating mechanism 3, and the described drilling blowing mechanism 5 is slidably connected to the support frame 1, the carrying mechanism 6 is slidably connected to the clamping mechanism 2 and is slidably connected to the saw mechanism 4, and the air pump 7 is fixedly connected to the support frame 1 and communicated with the drilling blowing mechanism 5 through the air pipe .

[0032] Put the nuts on the two bearing cross columns 6-4 between the two clamping seats 2-5, drive the two-way threaded rod 2-2 through the clamping motor 2-1 to drive the two clampin...

specific Embodiment approach 2

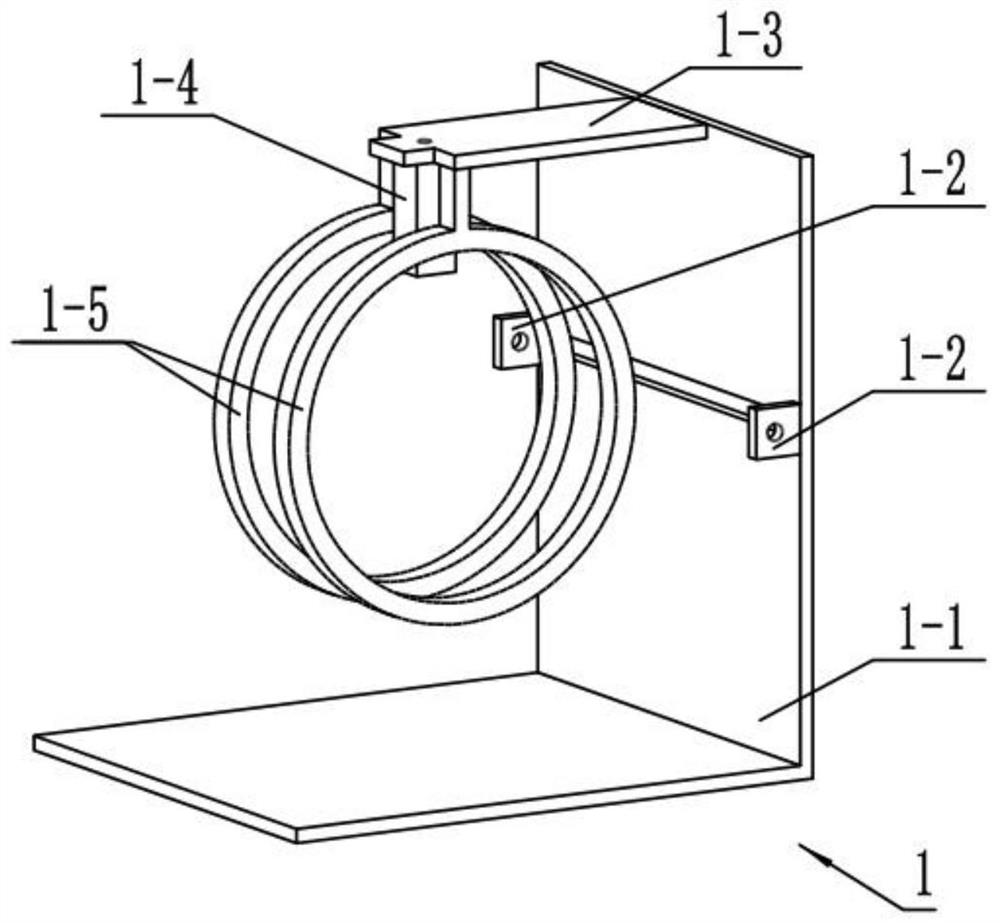

[0033] Such as Figure 1-8 As shown, the support frame 1 includes a support plate 1-1, a fixed plate 1-2, an upper arm plate 1-3, a drilling fixing pipe 1-4 and an external gear ring 1-5, and the support plate 1-1 The upper end of the upper arm plate is fixedly connected with the upper arm plate 1-3, the left and right sides of the front end of the upper arm plate 1-3 are fixedly connected with the outer gear ring 1-5, and the drilling fixing pipe 1-4 is fixedly connected with the upper arm plate The lower end surface of 1-3 is located between the two outer toothed rings 1-5, two fixed plates 1-2 are provided, and the two fixed plates 1-2 are fixedly connected to the supporting plate 1-1.

specific Embodiment approach 3

[0034] Such as Figure 1-8 As shown, the clamping mechanism 2 includes a clamping motor 2-1, a bidirectional threaded rod 2-2, a clamping arm 2-3, a clamping shaft 2-4 and a clamping seat 2-5, and a bidirectional threaded rod The two ends of 2-2 are rotationally connected to the fixed plate 1-2 respectively, and the clamping motor 2-1 is fixedly connected to one of the fixed plates 1-2, and the output of the two-way threaded rod 2-2 and the clamping motor 2-1 The shaft is fixedly connected, and there are two clamping arms 2-3, and the two clamping arms 2-3 are symmetrically threaded on the two-way threaded rod 2-2, and the rear ends of the two two-way threaded rods 2-2 are connected to the The support plate 1-1 is slidingly connected, the inner sides of the front ends of the two bidirectional threaded rods 2-2 are fixedly connected with the clamping shaft 2-4, and the inner ends of the two clamping shafts 2-4 are fixedly connected with the clamping seat 2- 5.

[0035] The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com