A kind of fast peeling equipment for sugarcane

A fast, sugarcane technology, applied in the peeling of vegetables or fruits, food science, applications, etc., can solve the problems of slow peeling speed, waste of sugarcane pulp, and inability to remove external dust and soil, so as to avoid contact and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

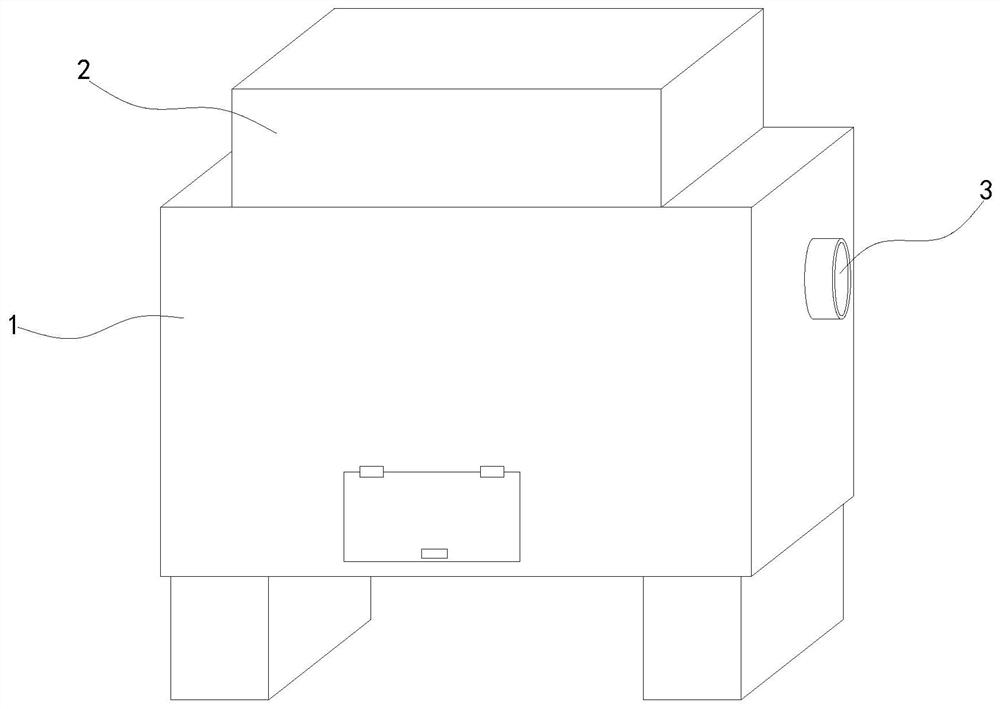

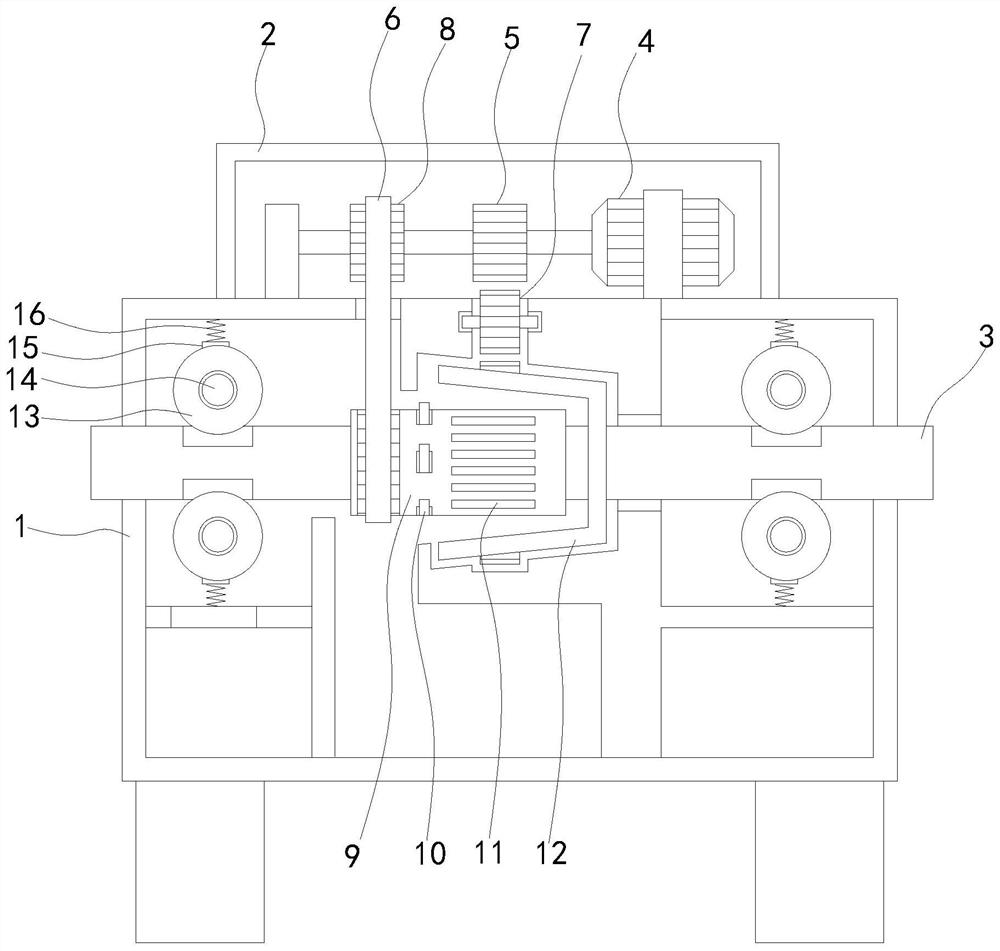

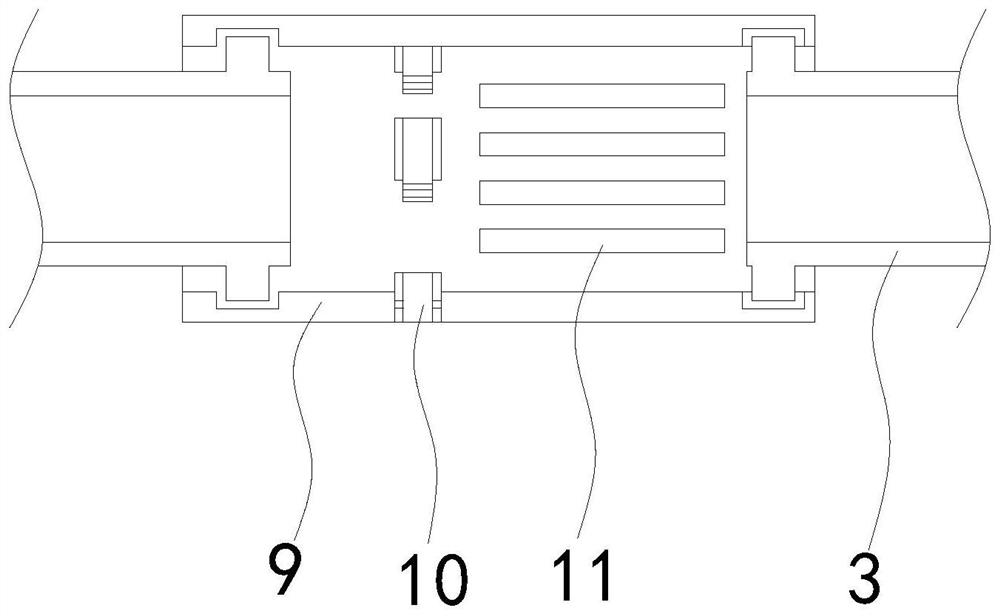

[0029] see Figures 1 to 9 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of a quick peeling equipment for sugarcane.

[0030] A sugarcane rapid peeling equipment, comprising a device main body 1, a drive box main body 2 is fixedly installed on the upper end of the device main body 1, a pipe 3 is fixedly installed inside the device main body 1, a peeling device 9 is movably connected to the middle end of the pipe 3, and the device main body 1 Rotating wheels 13 are installed on the left and right sides of the interior, and a slag suction device 12 is fixedly installed inside the device main body 1 .

[0031] In the specific implementation, the first motor 4 is fixedly installed on the right end of the drive box main body 2, the second gear 6 is fixedly installed on the outer side of the power output shaft at the left end of the first motor 4, and the outer side of the second gear 6 is engaged with the transmission belt 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com