A kind of spiral flexible force notoginseng peeling machine

A flexible force and peeling machine technology, which is applied in the fields of grain pod removal, grain germ removal, and grain processing, etc., can solve the problems of low peeling efficiency, high labor cost, and low operation efficiency, and achieve low cost and convenient maintenance , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

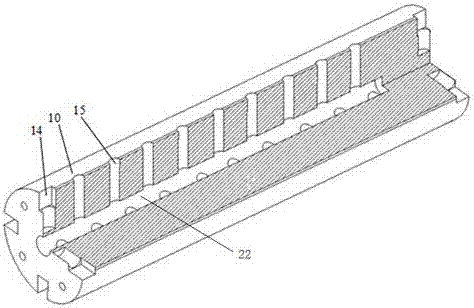

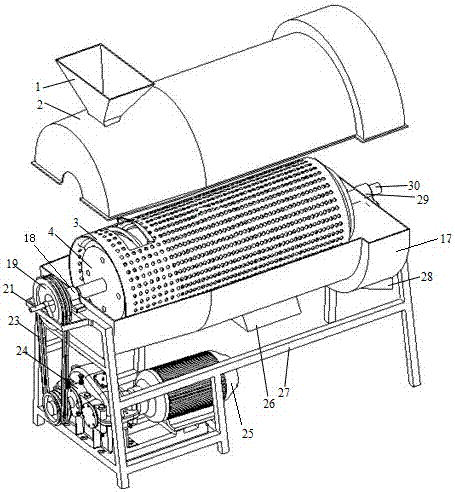

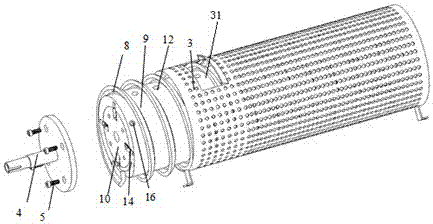

[0027] Embodiment 1: as Figure 1-9 As shown, the spiral flexible force Sanqihongzi peeling machine includes an upper casing 2, a peeling mechanism, a lower casing 17, a bearing seat I18, a pulley 19, a water pipe bracket 20, a water pipe 21, a belt 23, and a reducer 24. Motor 25, frame 27, bearing seat II 29; wherein the peeling mechanism includes a screen 3, a shaft core left end shaft 4, a pressure regulating spring 6, a pressure regulating top rail 7, a spiral blade 8, and a shaft core sleeve 9 , shaft core 10, shaft core right end shaft 30;

[0028] The lower casing 17 is fixed on the frame 27, the upper casing 2 is arranged on the lower casing 17, the upper casing 2 is provided with a material inlet 1, and the lower casing 17 is provided with a waste outlet 26 and a seed outlet 28 , the shaft core 10 in the peeling mechanism is set in the shaft core sleeve 9 and fixed by screws 16, the shaft core 10 is provided with a spring installation groove 14 and a water seepage ho...

Embodiment 2

[0031]Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, except that the diameter of the sieve hole on the screen is 3 mm; the angle between the spiral blade 8 and the horizontal plane is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com