Small efficient sand screening machine for civil engineering

A technology of civil engineering and sand screening machine, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of high labor intensity, low sand screening efficiency, and poor sand screening effect, so as to improve the effect and efficiency of sand screening , Prolong the residence time and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

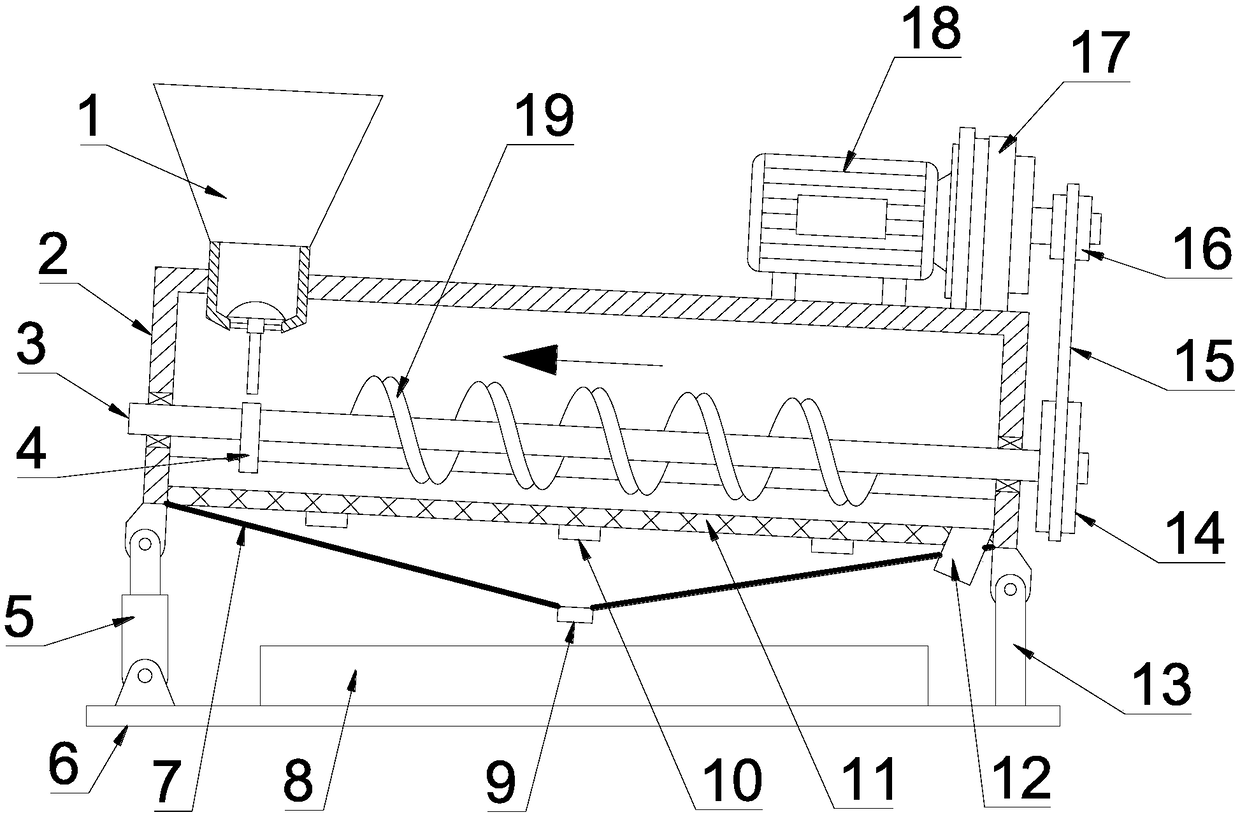

[0027] see Figure 1~4 , in an embodiment of the present invention, a small-scale high-efficiency sand screening machine for civil engineering includes a box body 2, the box body 2 is a lower opening structure, and the bottom of the box body 2 is equipped with a sand screen mesh plate 11, a sand screen net The plate 11 is a downward arc-shaped concave structure in the middle, and a plurality of vibrators 10 are arranged on the lower side of the sand screen plate 11, and the vibrator 10 drives the sand screen plate 11 to vibrate, which is beneficial to sieve out the sand material. The bottom of the body 2 is also provided with a hopper 7, the middle part of the hopper 7 is provided with a discharge pipe 9, the hopper 7 is used to guide the sand material, and the discharge pipe 9 is used to discharge the sand material. The right end of the bottom of the body 2 is provided with a slag discharge pipe 12 for discharging impurities on the upper right side of the sand screen plate 11...

Embodiment 2

[0030] see Figure 1~3 , the difference between this embodiment and embodiment 1 is:

[0031] In this embodiment, a base 6 is provided below the box body 2, and a receiving groove 8 for holding the sand discharged from the discharge pipe 9 is arranged on the base 6, and the left and right ends of the bottom of the box body 2 are provided with There are telescopic device 5 and strut 13, the upper ends of said telescopic device 5 and strut 13 are hingedly connected with box body 2, the lower end of telescopic device 5 is hingedly connected with base 6, and the lower end of strut 13 is fixedly arranged on base 6, through telescopic The angle of the box body 2 can be adjusted when the device 5 works.

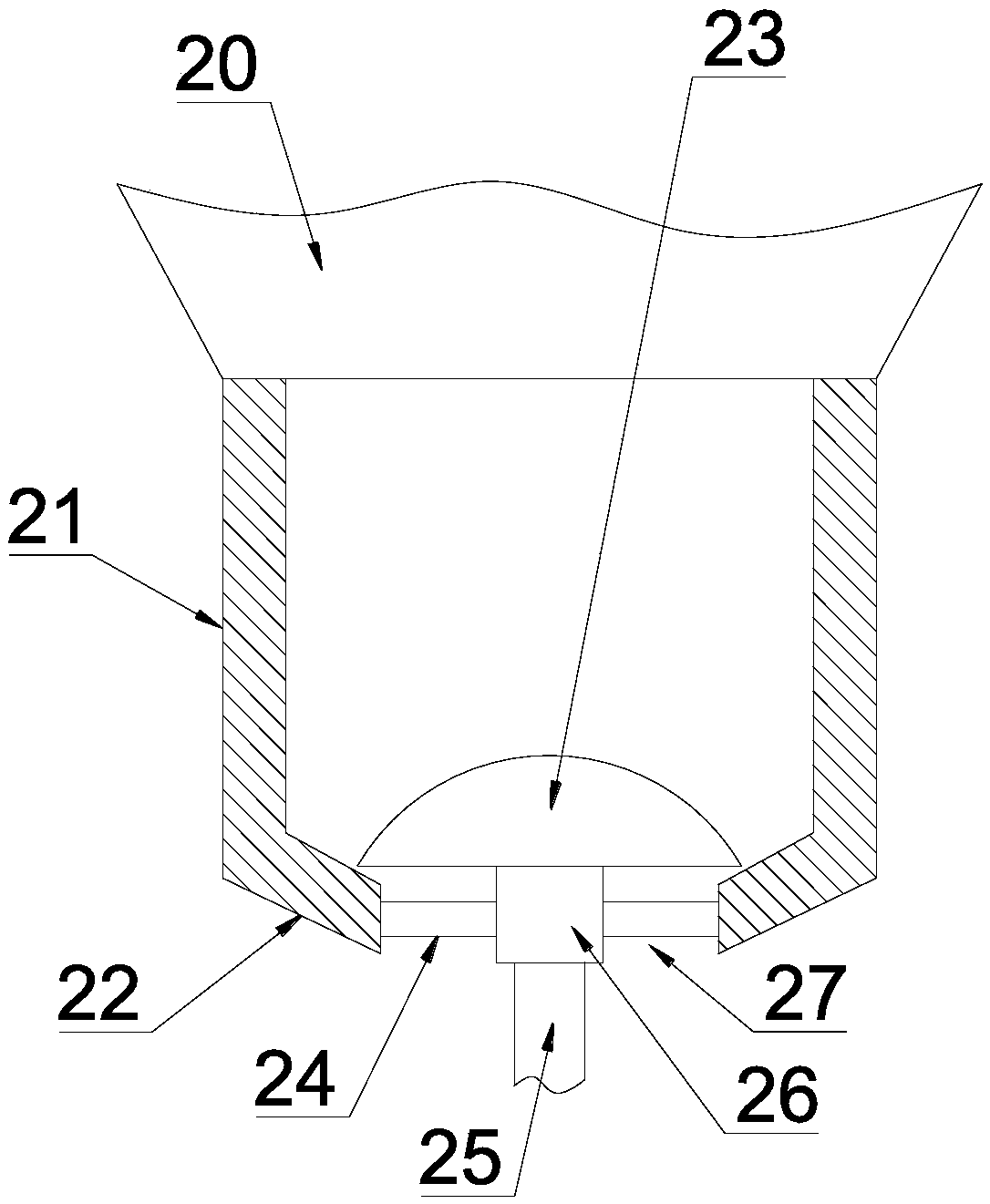

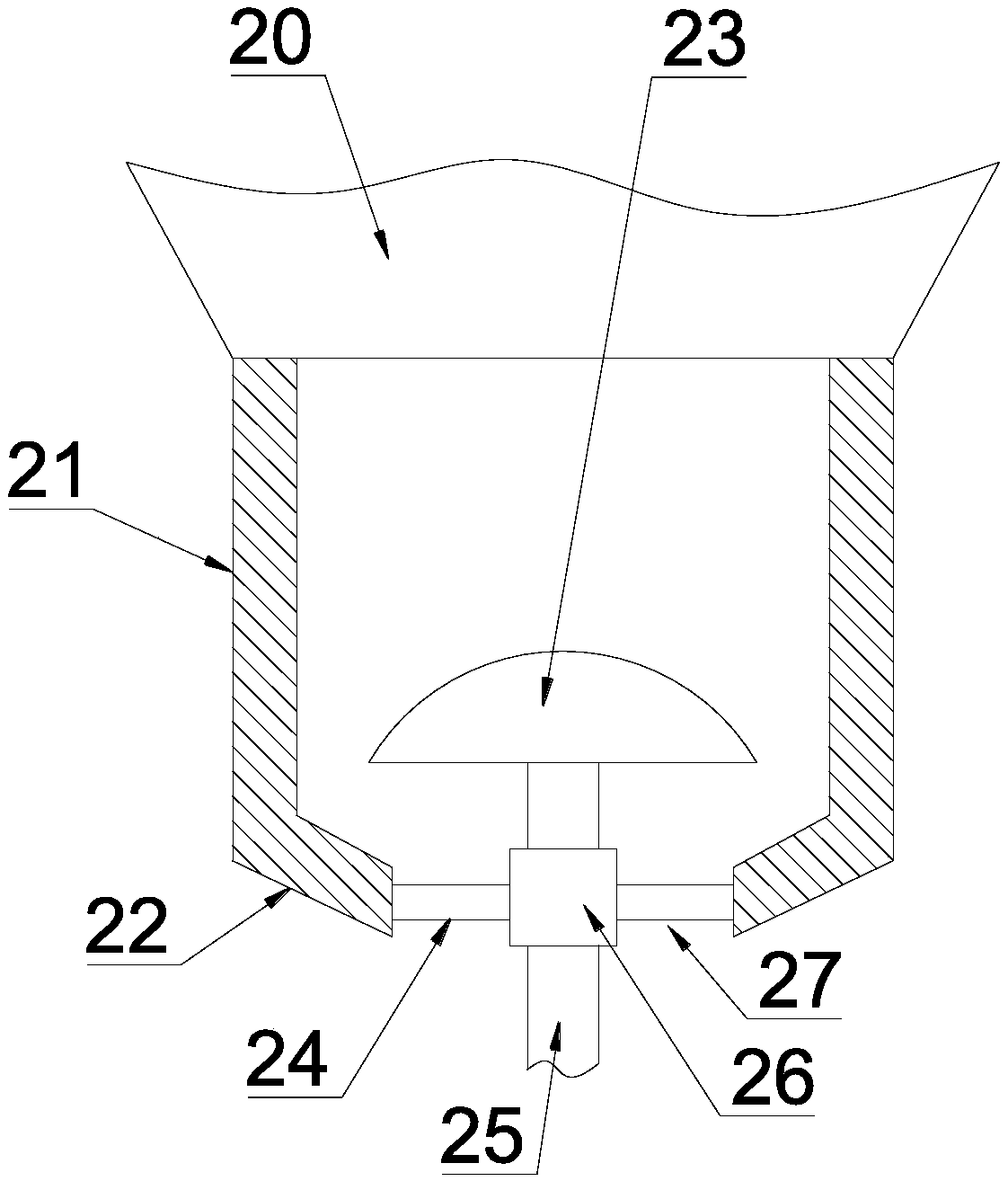

[0032] In this embodiment, a feeding mechanism 1 is provided on the left side of the top of the box body 2, and the feeding mechanism 1 includes a feeding pipe 21. The lower end of the feeding pipe 21 extends to the inner side of the box body 2, and feeds The feed pipe 21 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com