Device to automatically place nut in mold

A nut, automatic technology, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of low embedded position accuracy, prolonged processing cycle, high labor cost, improve product qualification rate and production efficiency, and reduce work intensity. , the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For better understanding and implementation, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0028] Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the technical field of the invention. The terms used herein in the description of the present invention are for the purpose of describing specific embodiments only, and are not intended to limit the present invention.

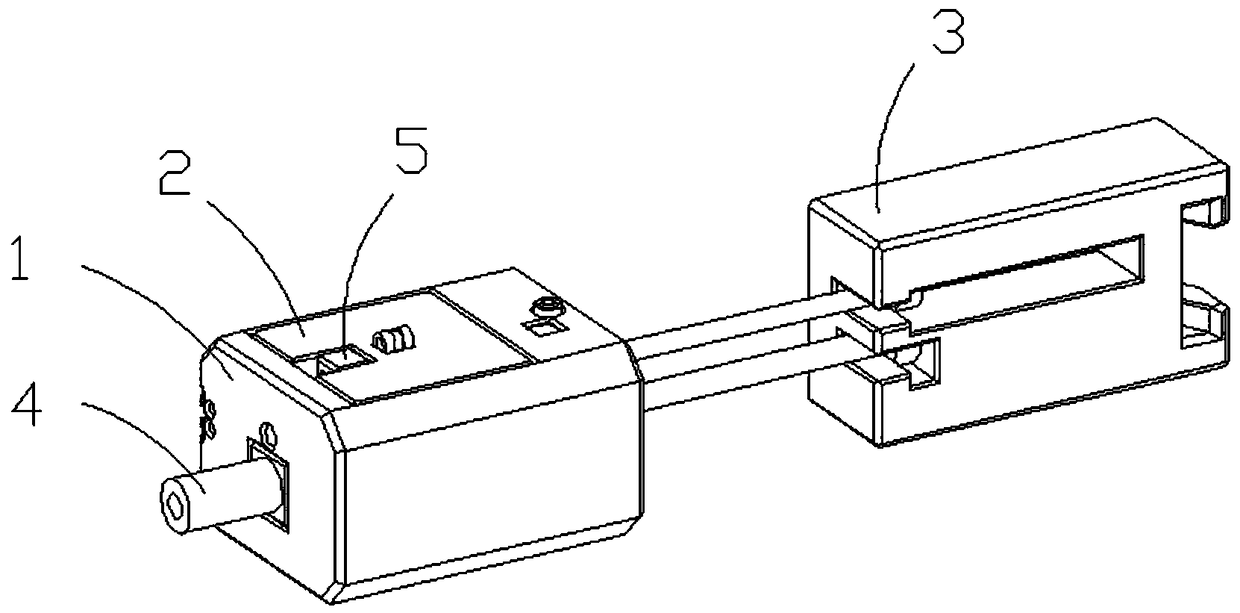

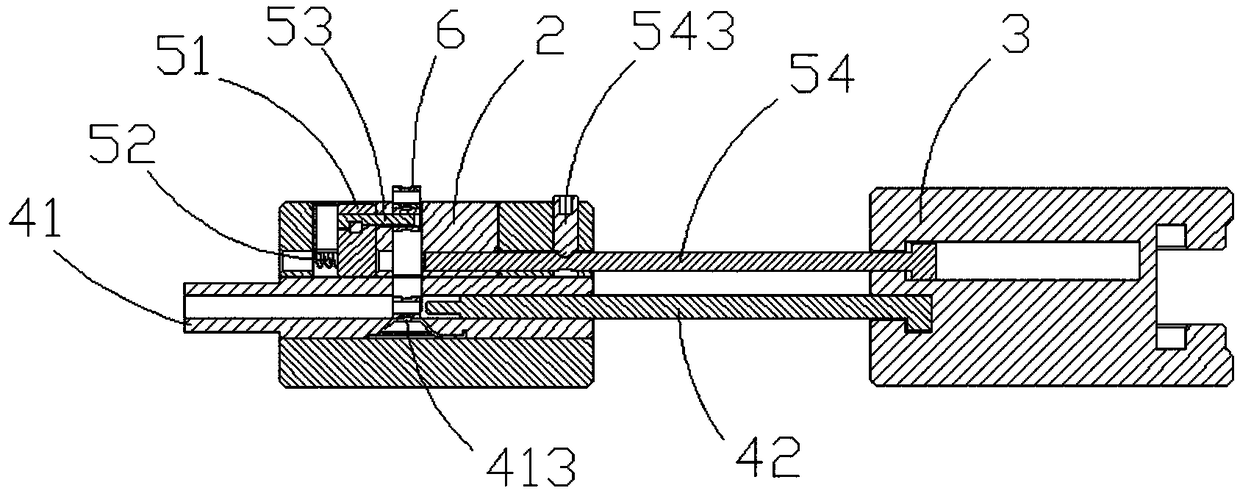

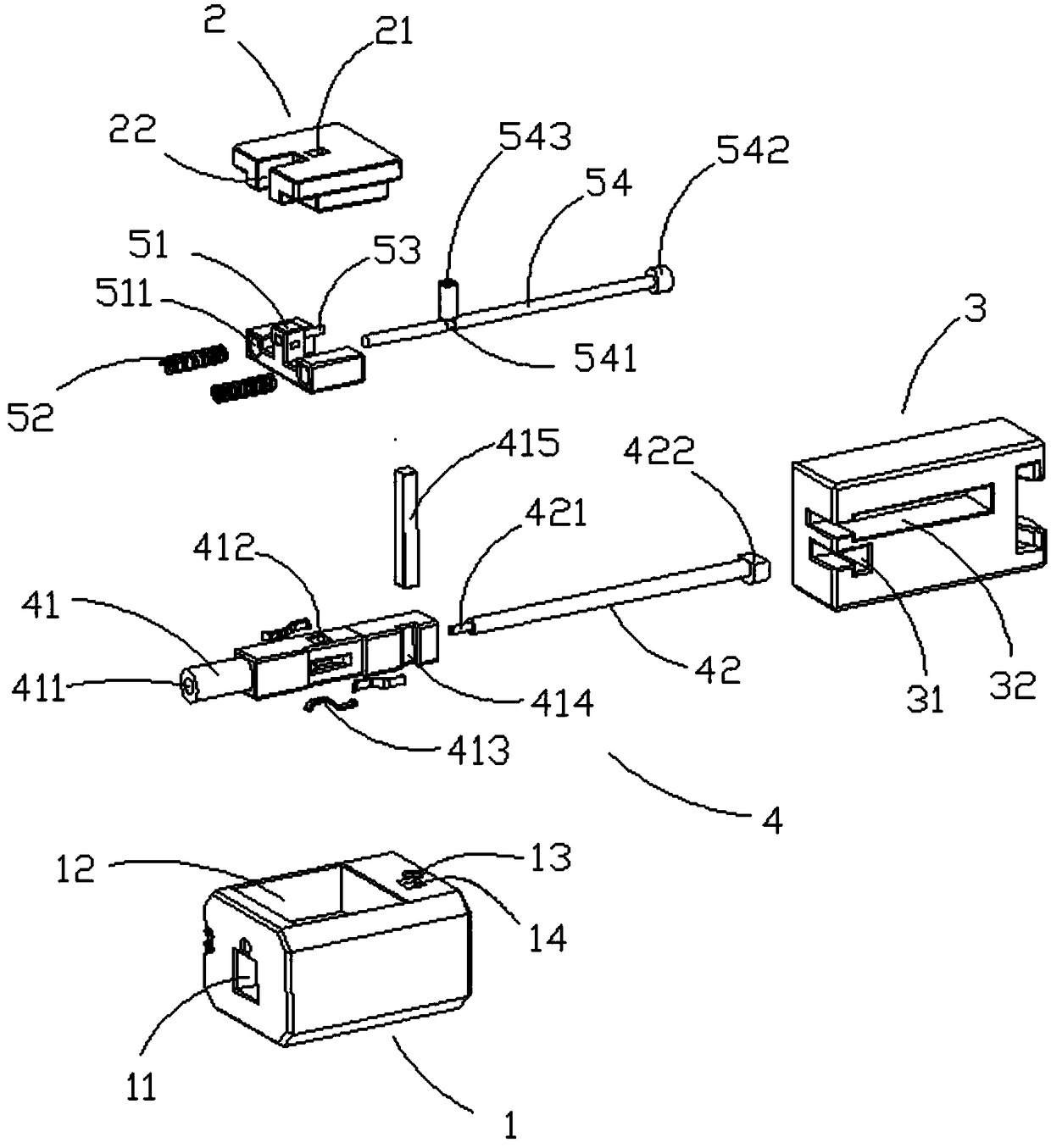

[0029] refer to figure 1 , figure 2 and image 3 , the present invention discloses a device for automatically placing nuts in a mold, the device for automatically placing nuts in a mold can be applied to an injection mold, and can be externally connected with a nut conveying device to realize the function of automatically placing nuts 6 in the mold cavity; and No m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com