A pvc pipe spin welding device

A technology of spin welding and PVC pipes, which is applied in the direction of tubular objects, household appliances, and other household appliances. It can solve the problems of weak connection, uneven thickness of joints, and poor sealing of pipe joints, etc., to achieve welding Quick and effective, beautiful welding point, strong sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

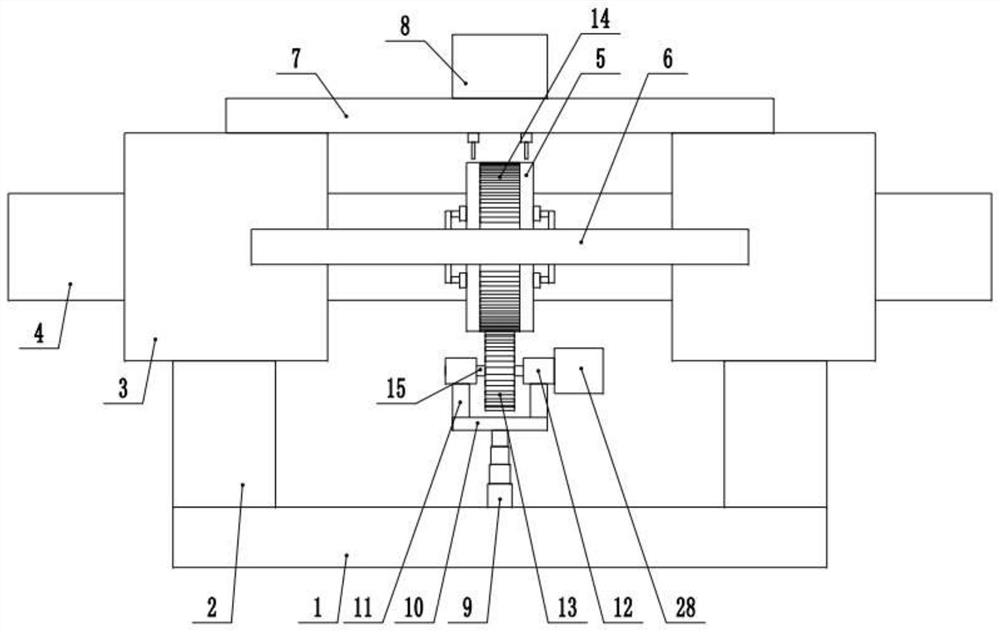

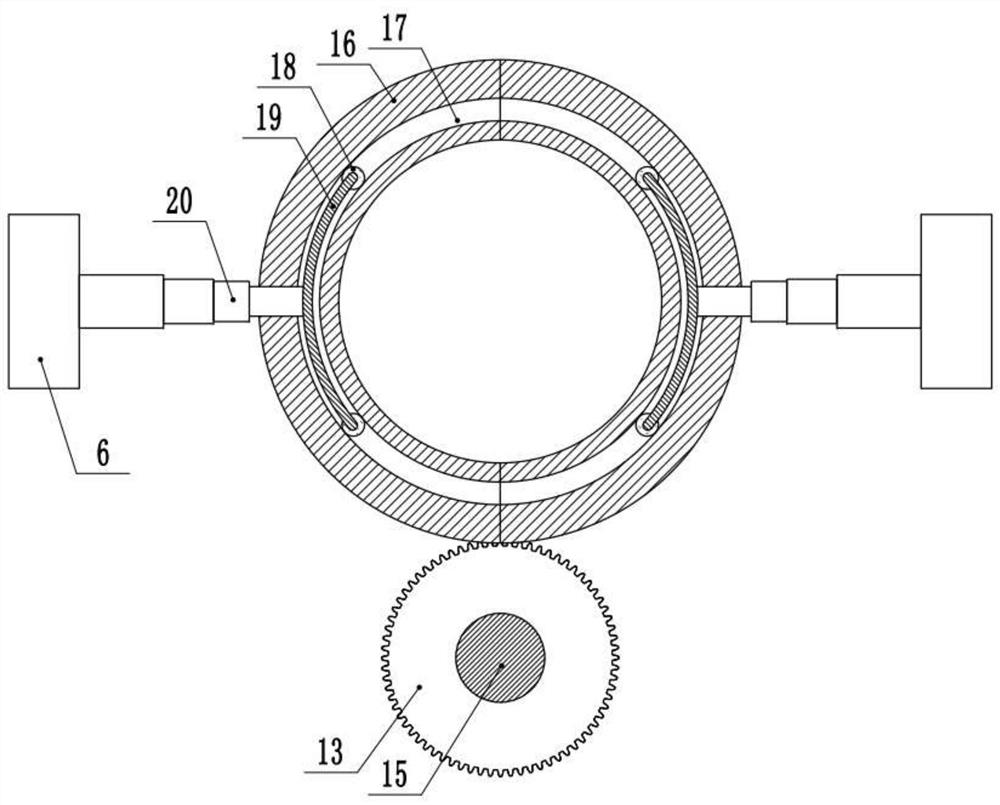

[0023] see figure 1 , a PVC pipe rotary welding device, including a base 1, the two ends of the top surface of the base 1 are fixedly connected to the support seat 2, the top of the support seat 2 is fixedly connected to the fixed seat 3, and the two fixed seats 3 are fixed A PVC pipe 4 runs through, a welding jacket 5 is provided between the two fixed seats 3, the top of the fixed seats 3 is fixedly connected to the top plate 7, and the top plate 7 is provided with a power connection mechanism, and the base The center of the bottom end of 1 is fixedly connected to the hydraulic telescopic rod 9, and the top of the hydraulic telescopic rod 9 is fixedly connected to the lifting plate 10, and both ends of the top surface of the lifting plate 10 are fixedly connected to the connecting column 11, and the top of the connecting column 11 Fixedly connected to the fixed sleeve 12, one side of the fixed sleeve 12 is fixedly connected to the driving motor 28, a driving gear 13 is arrang...

Embodiment 2

[0027] see figure 1 and figure 2 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the slideway 17 is circular, the connecting rod 19 is arc-shaped corresponding to the slideway 17, and the fixed sleeve 12 A bearing is arranged inside, and the rotating shaft 15 is fixedly connected with the bearing.

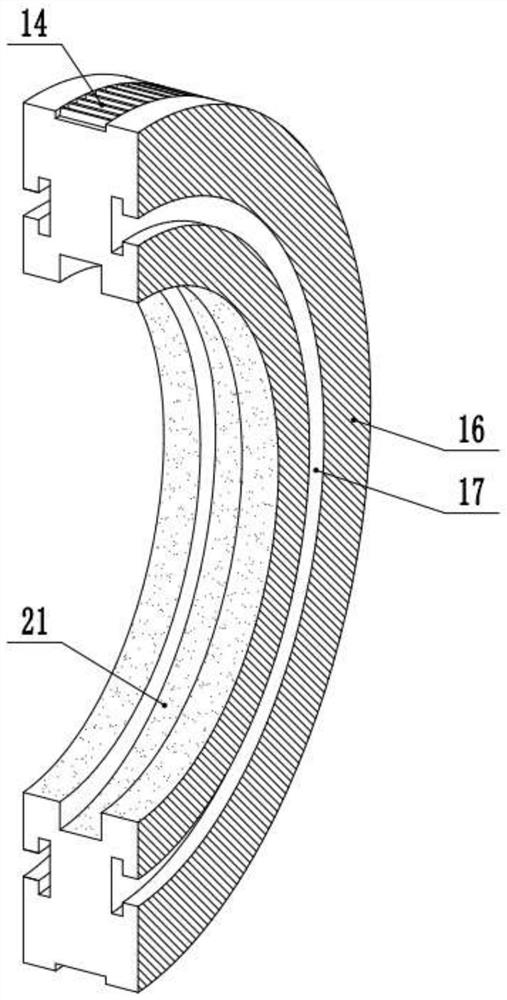

[0028] In the implementation process of the present invention, first two PVC pipes 4 are placed through the fixing seat 3, then the ends of the two PVC pipes 4 are aligned, and plastic welding rods are placed in the welding grooves 21 in the two semicircular ring sleeves 16, Restart the electric telescopic rod 20 to move the two semi-circular ring sleeves 16 until the joints of the two PVC pipes 4 are covered, then turn the welding overcoat 5, align the plug hole with the plug 27, and control the electromagnet 23 to power off. Under the action of the spring 24, the pressure plate 25 drives the connecting seat 26 and the plug 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com