Laser beam welding method and apparatus

A laser beam and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low productivity, the contact surface of overlapping plates that cannot be welded, and the complicated structure of the welding system, so as to improve productivity, high efficiency and fast Effects of Welding, Simple Processes and Arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

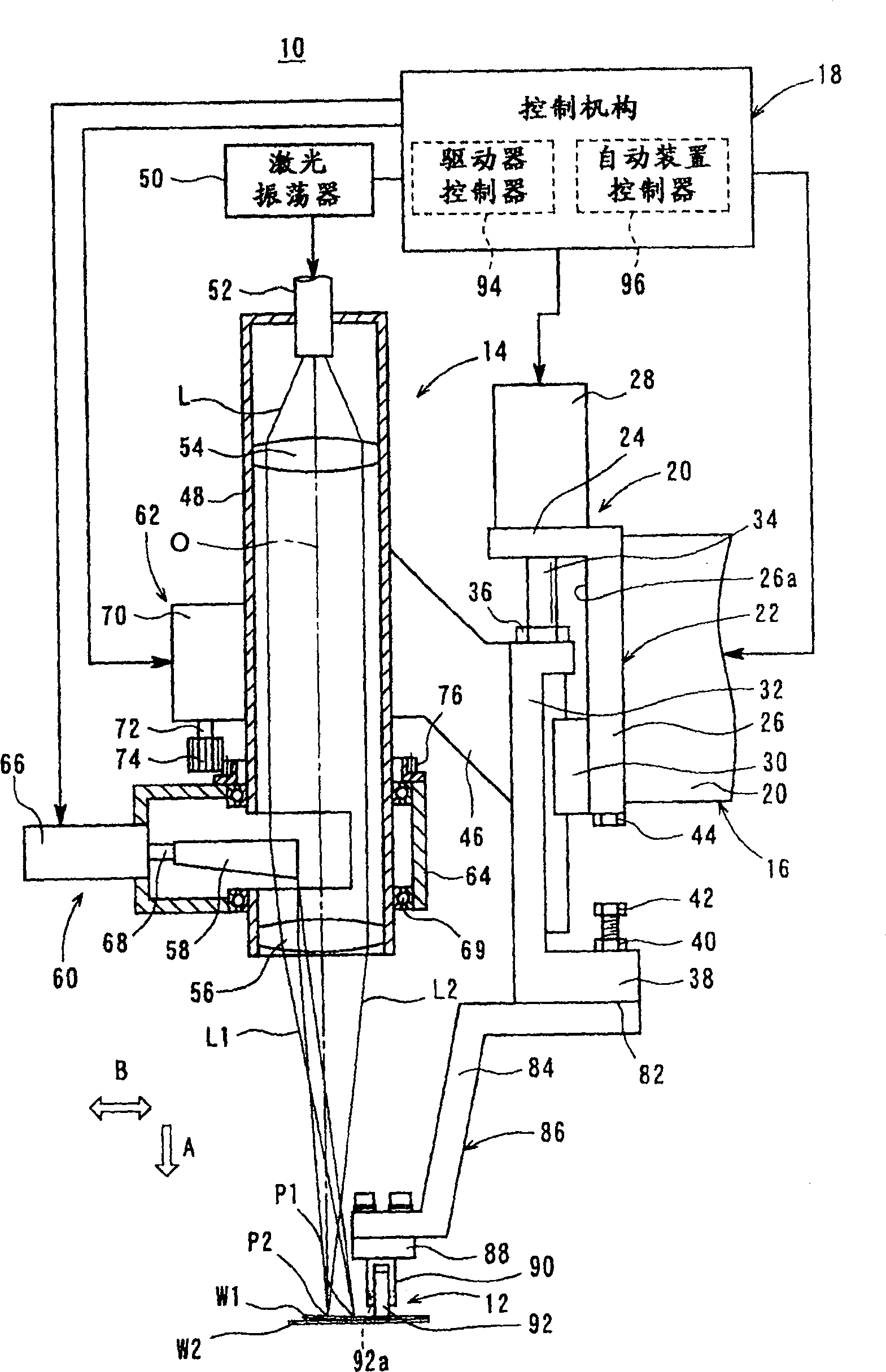

[0048] figure 1 The laser beam welding apparatus 10 performing the laser beam welding method according to the first embodiment of the present invention is shown in side view, partial sectional view and block diagram.

[0049] The laser beam welding apparatus 10 is not limited to one particular use, but may be used for welding galvanized steel sheets W1, W2 such as roof panels of motor vehicles.

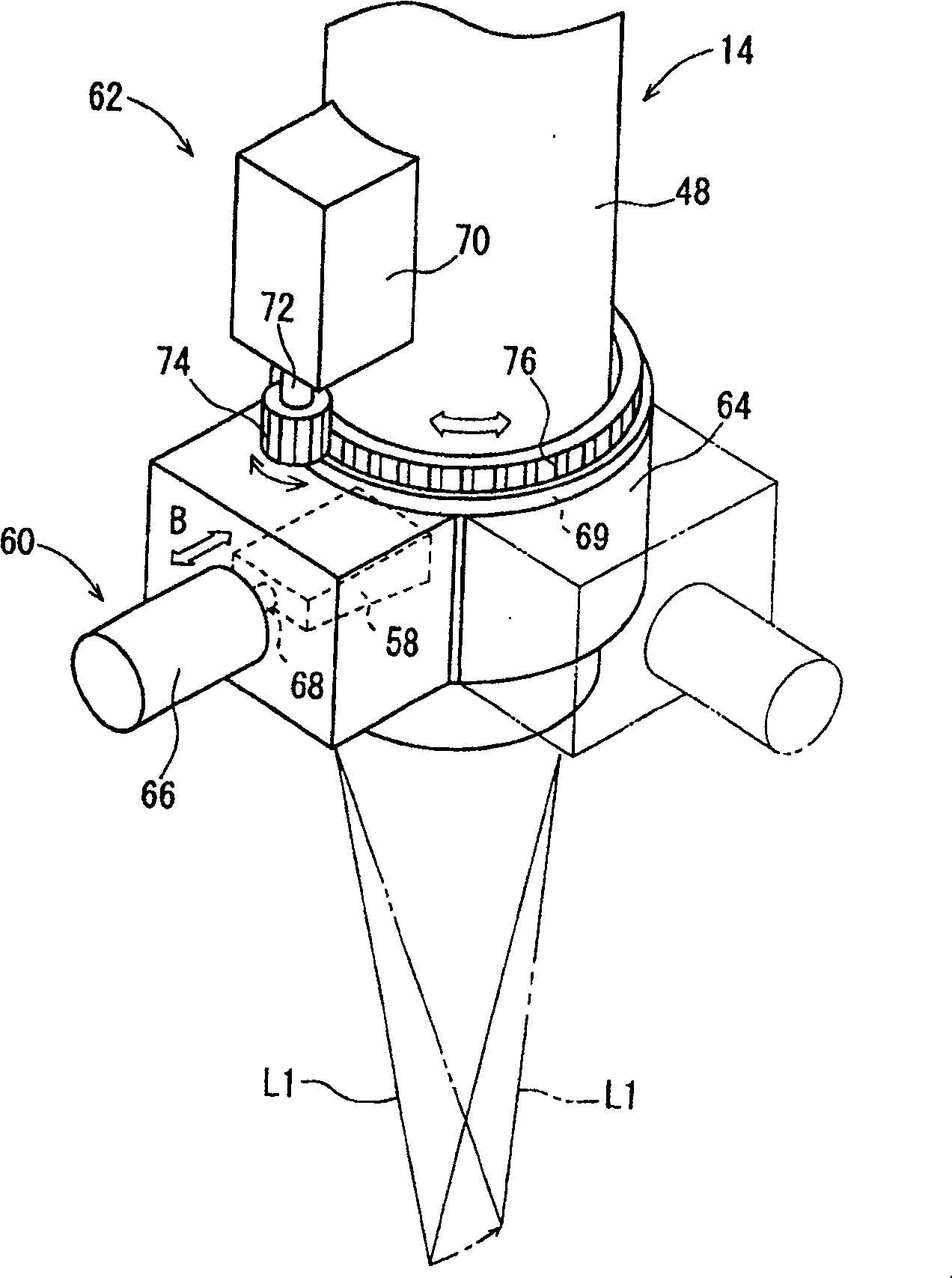

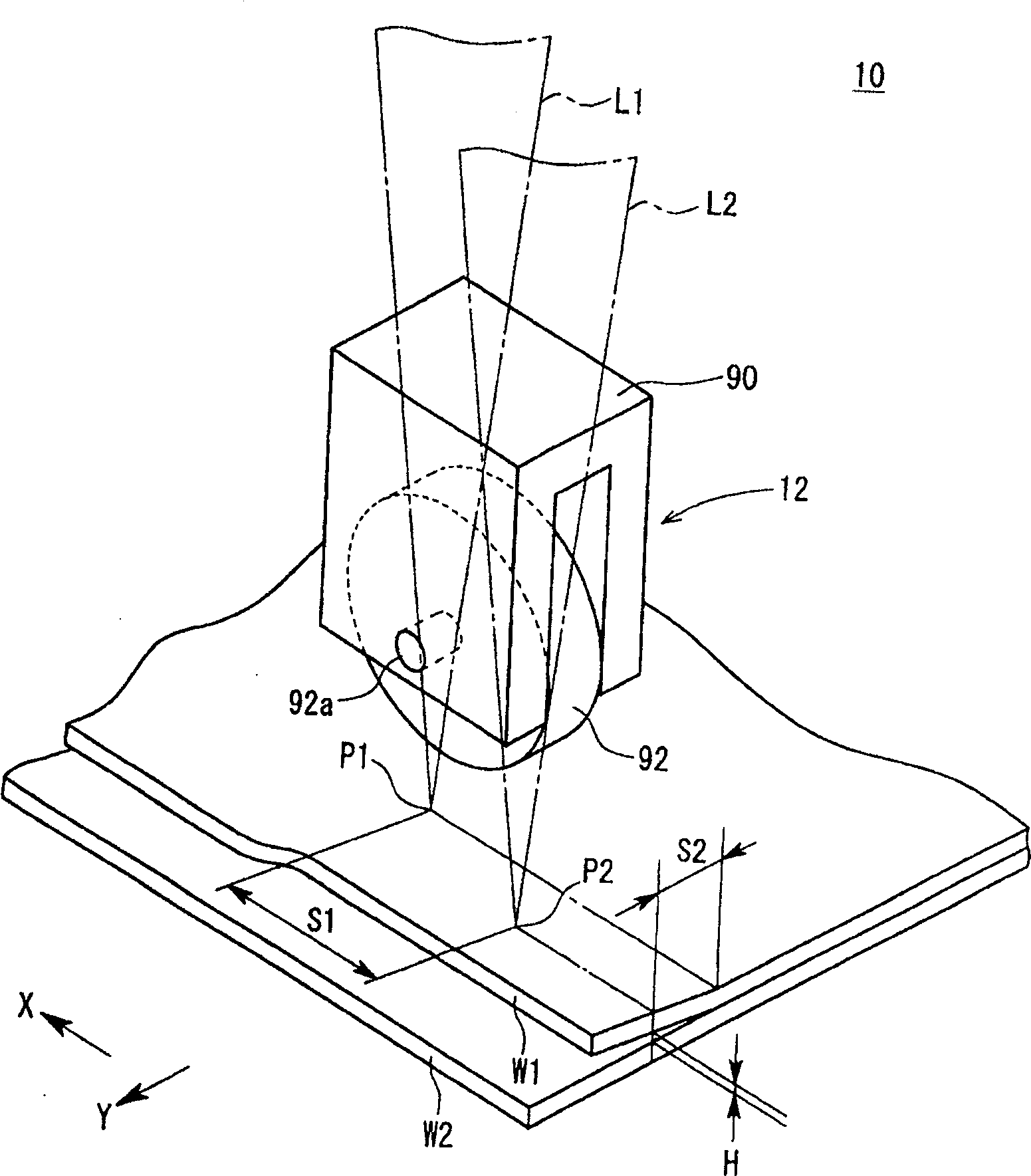

[0050] The laser beam welding equipment 10 includes a holding mechanism 12, a laser beam applying mechanism 14, a mechanical arm (moving mechanism) 16, and a control mechanism 18, wherein the holding mechanism 12 is used to position and hold the welding areas of the steel plates W1, W2, and the laser beam The beam applying mechanism 14 is used to apply the first laser beam L1 to the heating area P1 of the steel plate W1 near the holding mechanism 12 to heat the heating area P1 and to apply the second laser beam L2 to the area separated from the first laser beam L1 by a given distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com