A method of brazing litz wire and copper bar

A Litz wire and brazing technology, applied in the field of transformers, can solve problems such as increased wire resistance and increased power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

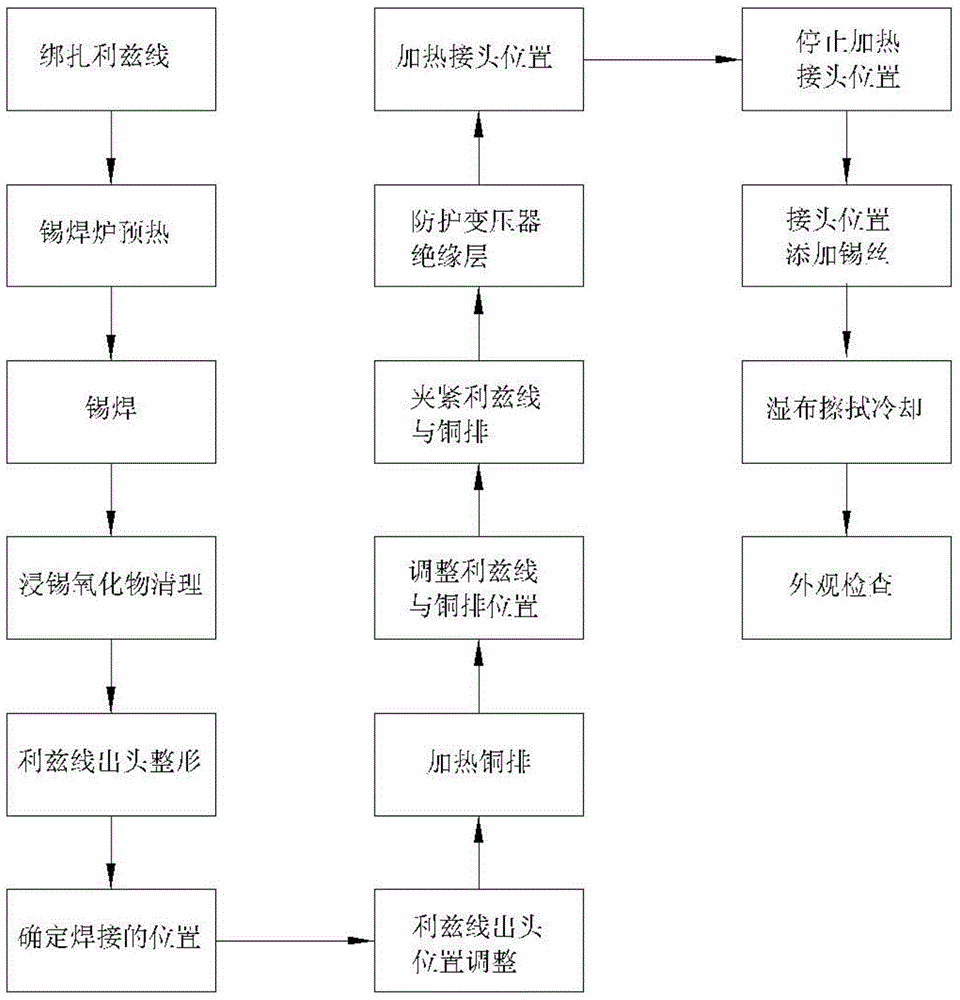

[0026] A method for brazing litz wires and copper bars, wherein the number of litz wires is 800, the diameter of each litz wire is 0.16 mm, the thickness of the copper bars is 3 mm, and the width is 20 mm. The method is as follows figure 1 shown, including the following steps:

[0027] (1) After spreading out the single-strand or multi-strand Litz wires, bind the Litz wires with a thin copper wire with a diameter of 1 mm;

[0028] (2) Preheat the soldering furnace, the preheating temperature is 380 degrees Celsius, and maintain this temperature;

[0029] (3) soldering, the soldering temperature is 375-385 degrees Celsius, the soldering time is 50 seconds, and the soldering length is 5-15 mm;

[0030] (4) Use a cleaning stick to clean the immersion tin oxide on the Litz wire outlet in time;

[0031] (5) While it is hot, use a vise to shape the tinned Litz wire until there is no excess tin;

[0032] (6) Determine the welding position. According to the actual production of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com