Ink loading device for digital printing

A loading device and digital printing technology, which is applied in printing and other directions, can solve the problems of adding ink, ink leakage, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

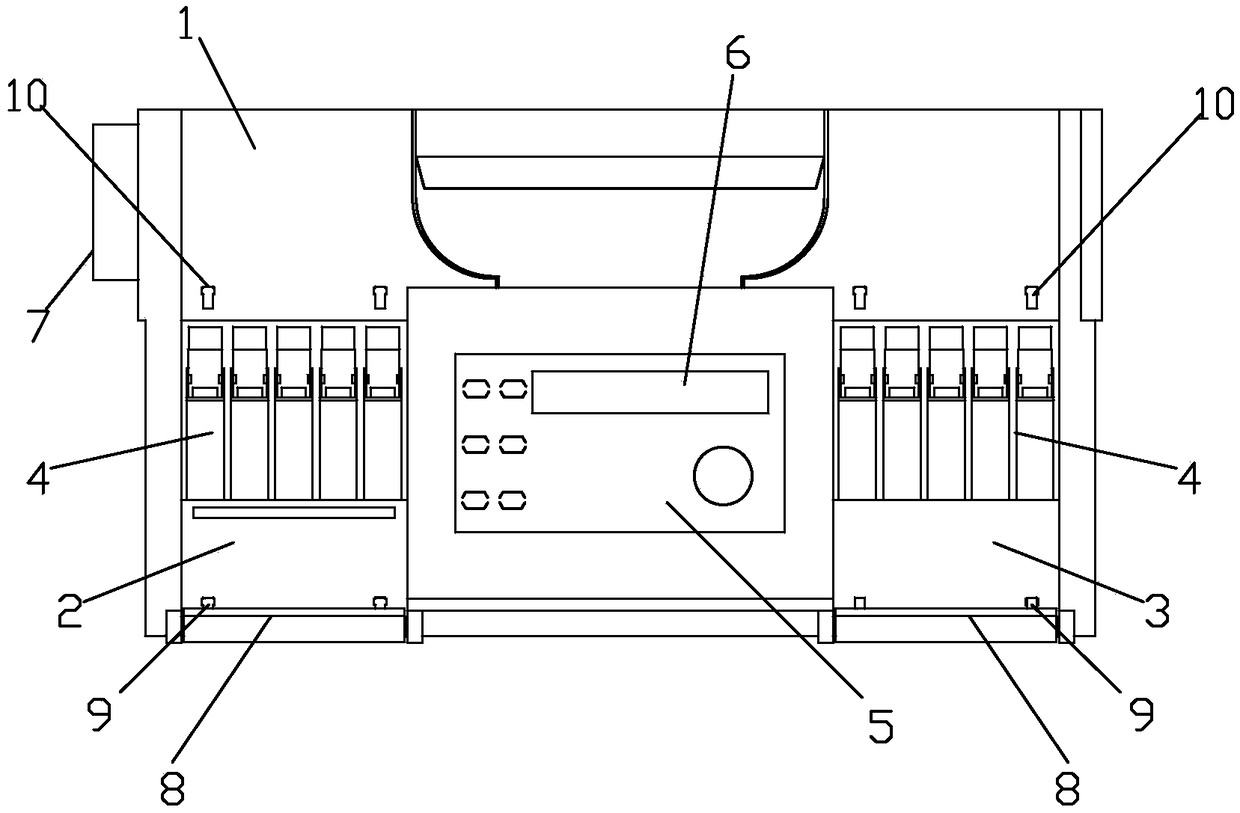

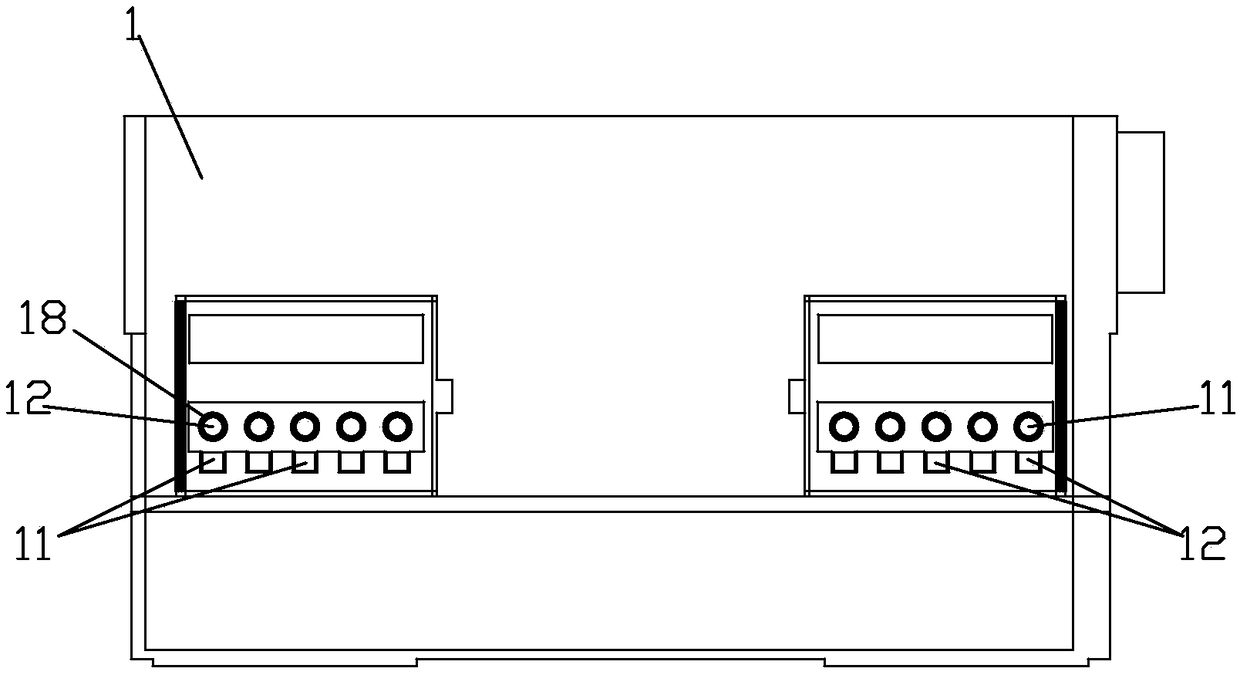

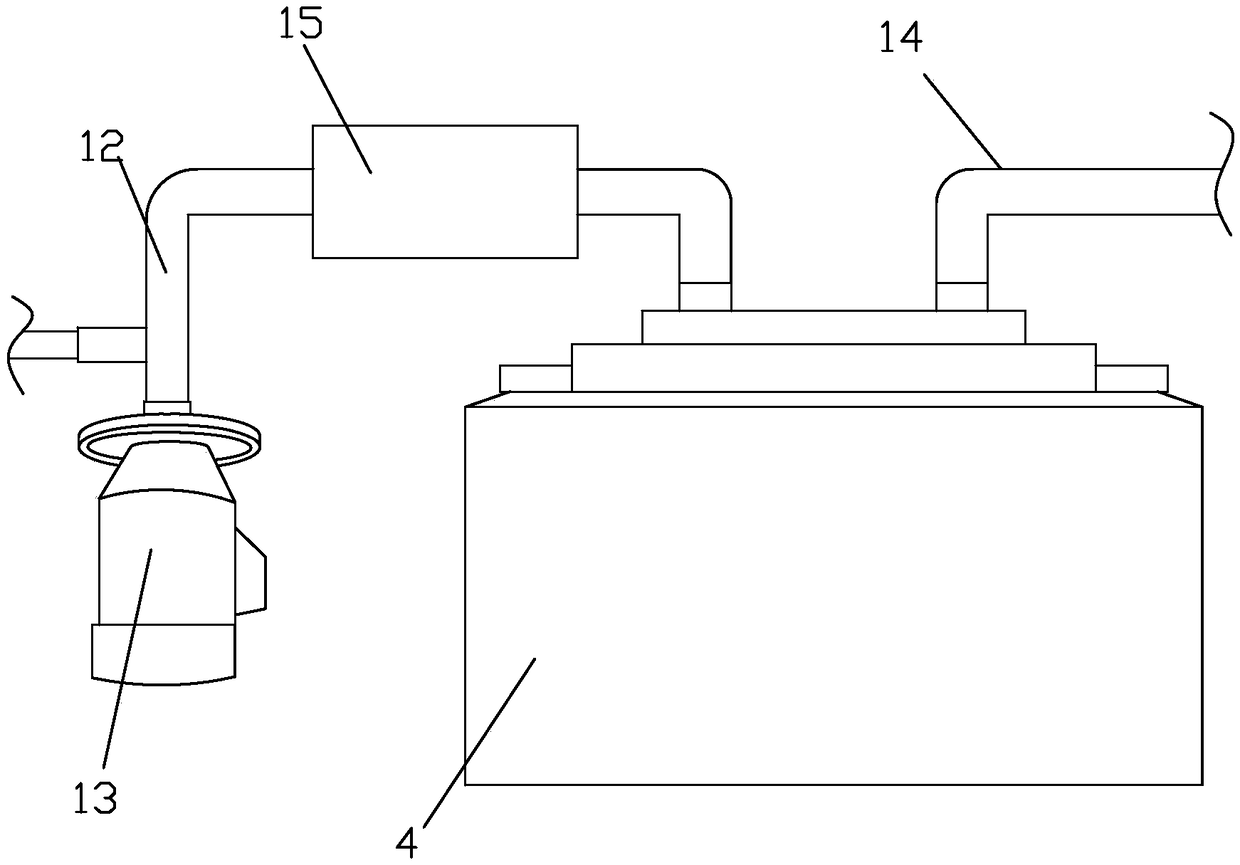

[0036] like Figure 1 to Figure 9 As shown, an ink loading device for digital printing includes a machine body 1, the front of the machine body 1 is provided with a first ink cartridge area 2 and a second ink box area 3, and the first ink box area 2 and the second ink box area 3 are respectively located on the front of the machine body 1 5 ink cartridges 4 are installed in the first ink cartridge area 2 and the second ink cartridge area 3, and the five ink cartridges 4 are arranged side by side; the first ink box area 2 and the second ink box area 3 are equipped with Cover door 8, the lower end of cover door 8 is hinged with a door shaft; cover door 8 is provided with door catch 9, and the front of body 1 is provided with door catch hole 10, and door catch hole 10 is positioned at the first ink cartridge area 2 and the second ink cartridge area 3, the door catch 9 is matched with the door button hole 10. When closing the door, the cover door 8 is rotated from bottom to top, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com