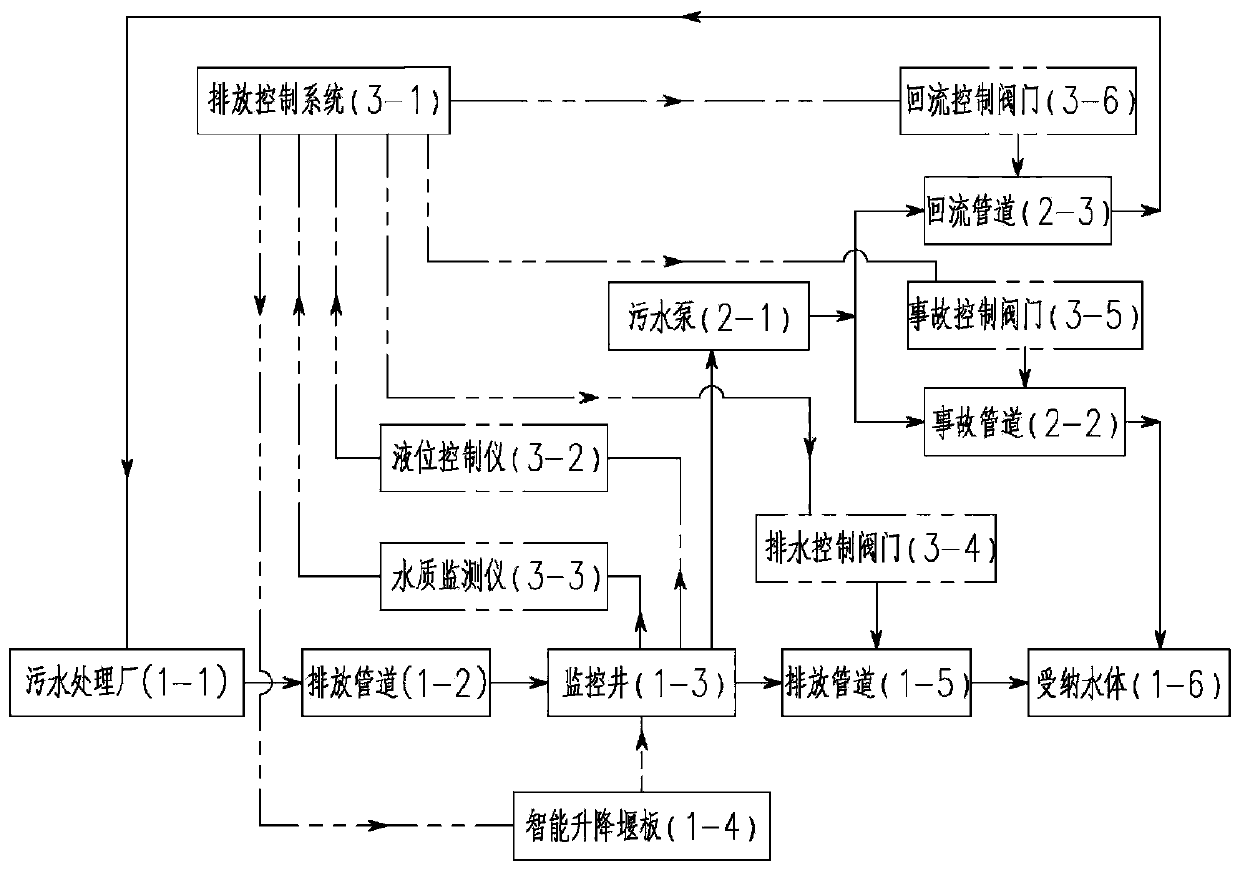

A tail water safety discharge system of a sewage treatment plant and its control method

A sewage treatment plant, safe discharge technology, applied in water treatment parameter control, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of high stability and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

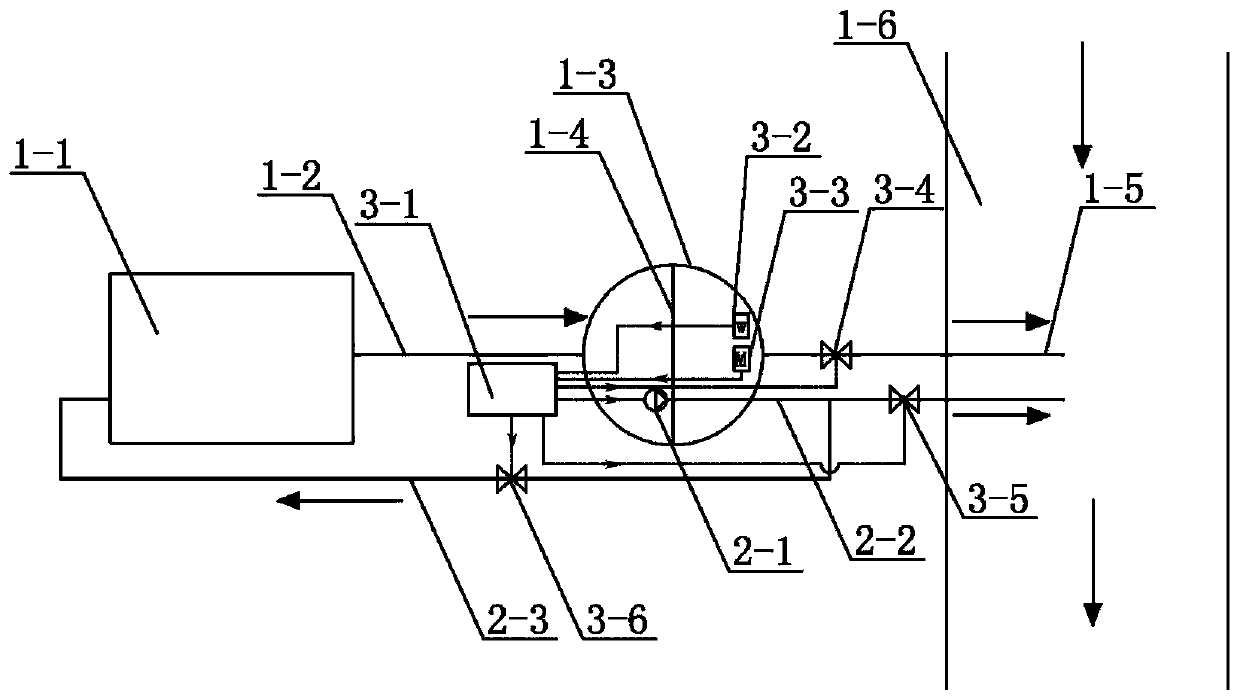

Embodiment 1

[0049] When the measured water level is 4.2m≤normal water level 5.0m, the discharge control system 3-1 controls the intelligent lifting weir plate 1-4 to maintain the original set height of 3.9m, and the drainage control valve 3-4 is normally opened;

[0050] The water quality in the monitoring well 1-3 is measured by the water quality monitor 3-3, and the data is fed back to the discharge control system 3-1; when the measured value of COD is 35mg / L≤the measured value of COD is 50mg / L, and the measured value of ammonia nitrogen is 3.5mg / L≤ammonia nitrogen Measured value 5mg / L, TN measured value 12.5mg / L≤TN measured value 15mg / L, TP measured value 0.32mg / L≤TP measured value 0.5mg / L, emission control system 3-1 controls intelligent lifting weir plate 1 -4 maintains the original set height, and the drainage control valve 3-4 is normally opened.

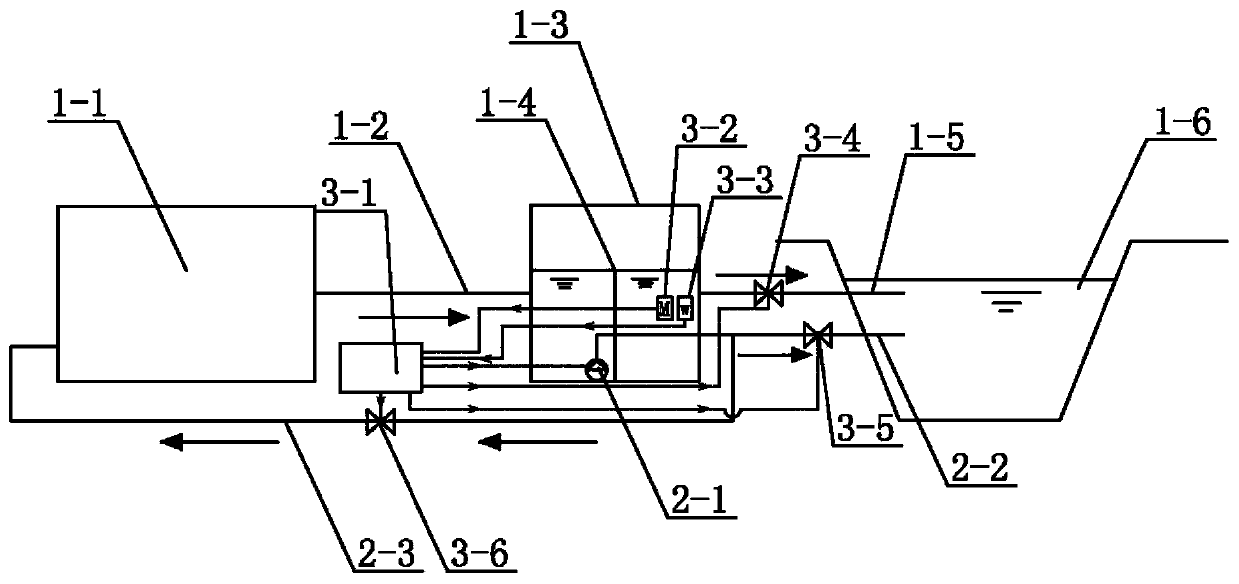

Embodiment 2

[0052] Others are the same as embodiment 1, the difference is:

[0053] When the measured water level is 5.5m>normal water level 5.0m, the discharge control system 3-1 controls the intelligent lifting weir plate 1-4 to be higher than the original set height, and closes the drainage control valve 3-4 to ensure that the receiving water body 1-6 does not enter the monitoring Wells 1-3. Simultaneously start the sewage pump 2-1 through the accident pipeline 2-2, open the accident control valve 3-5, close the backflow control valve 3-6, and ensure that the tail water is discharged into the receiving water body 1-6.

Embodiment 3

[0055] Others are the same as embodiment 1, the difference is:

[0056] When the measured value of COD is 55 mg / L>the measured value of COD is 50 mg / L, the measured value of ammonia nitrogen is 4.5 mg / L≤the measured value of ammonia nitrogen is 5 mg / L, the measured value of TN is 11.2 mg / L≤the measured value of TN is 15 mg / L, and the measured value of TP is 0.41 mg When / L≤TP measurement value is 0.5mg / L, the discharge control system 3-1 controls the intelligent lifting weir plate 1-4 to be higher than the original set height, and closes the drainage control valve 3-4 to ensure that the receiving water body 1-6 does not enter the monitoring Wells 1-3. Simultaneously start the sewage pump 2-1 through the return pipe 2-3, open the return control valve 3-6, close the accident control valve 3-5, and ensure that the tail water returns to the sewage treatment plant 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com