Antibacterial and anti-ultraviolet fabric and preparation method thereof

An anti-ultraviolet and fabric technology, applied in the field of textile fabrics, can solve the problems of anti-ultraviolet fabrics such as poor anti-washing effect, decline in anti-ultraviolet effect, and loss, and achieve high antibacterial and anti-ultraviolet properties, strong antibacterial properties, and good washability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

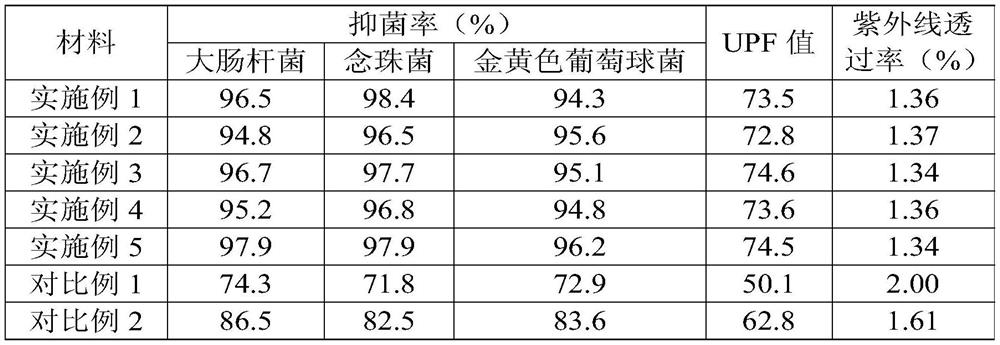

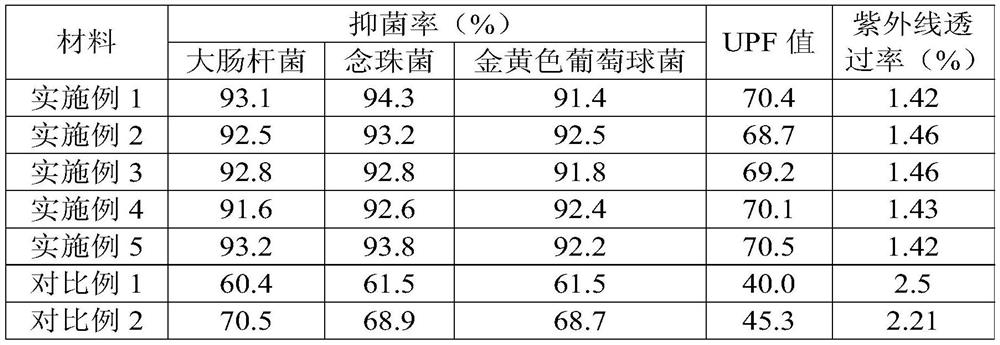

Examples

Embodiment 1

[0030] Antibacterial and anti-ultraviolet fabric and preparation method thereof

[0031] The raw materials for preparing antibacterial and anti-ultraviolet fabrics include: 100kg of polyester chips, 5kg of coconut shell fiber, 2.0kg of nano-zinc oxide, 1.5kg of nano-titanium oxide, 2.6kg of bamboo charcoal powder, 0.1kg of silane coupling agent, 0.2kg of chitosan, poly 0.4kg of ethylene glycol and 2.4kg of eucalyptus oil; among them, the polyester chips are alkali-soluble polyester chips with an intrinsic viscosity of 0.5dL / g-0.7dL / g, and the particle size of nano-zinc oxide is 20nm-50nm.

[0032] The antibacterial and anti-ultraviolet fabric is prepared by the following method:

[0033] Step S10, weighing the raw materials for preparing antibacterial and anti-ultraviolet fabrics according to the above weight parts;

[0034] Step S20, mixing the nano-zinc oxide, nano-titanium oxide, bamboo charcoal powder and silane coupling agent in the above parts by weight, and ball millin...

Embodiment 2

[0043] Antibacterial and anti-ultraviolet fabric and preparation method thereof

[0044] The raw materials for preparing antibacterial and anti-ultraviolet fabrics include: 100kg of polyester chips, 12kg of coconut shell fiber, 3.6kg of nano-zinc oxide, 0.6kg of nano-titanium oxide, 1.2kg of bamboo charcoal powder, 0.5kg of silane coupling agent, 0.1kg of chitosan, poly Ethylene glycol 0.5kg, eucalyptus oil 2.0kg; Among them, the polyester chip is an alkali-soluble polyester chip with an intrinsic viscosity of 0.5dL / g-0.7dL / g, and the particle size of nano-zinc oxide is 20nm-50nm.

[0045] The antibacterial and anti-ultraviolet fabric is prepared by the following method:

[0046] Step S10, weighing the raw materials for preparing antibacterial and anti-ultraviolet fabrics according to the above weight parts;

[0047] Step S20, mixing the nano-zinc oxide, nano-titanium oxide, bamboo charcoal powder and silane coupling agent in the above parts by weight, and ball milling and mi...

Embodiment 3

[0056] Antibacterial and anti-ultraviolet fabric and preparation method thereof

[0057] The raw materials for preparing antibacterial and anti-ultraviolet fabrics include: 100kg of polyester chips, 7kg of coconut shell fiber, 1.8kg of nano-zinc oxide, 1.8kg of nano-titanium oxide, 2.2kg of bamboo charcoal powder, 0.6kg of silane coupling agent, 0.4kg of chitosan, poly 0.2kg of ethylene glycol and 0.8kg of eucalyptus oil; among them, the polyester chips are alkali-soluble polyester chips with an intrinsic viscosity of 0.5dL / g-0.7dL / g, and the particle size of nano-zinc oxide is 20nm-50nm.

[0058] The antibacterial and anti-ultraviolet fabric is prepared by the following method:

[0059] Step S10, weighing the raw materials for preparing antibacterial and anti-ultraviolet fabrics according to the above weight parts;

[0060] Step S20, mixing the nano-zinc oxide, nano-titanium oxide, bamboo charcoal powder and silane coupling agent in the above parts by weight, and ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com