Sound shell wrapping cloth hot press

A technology of audio shell wrapping and hot press, which is applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc. Stability and other issues, to achieve the effect of eliminating internal stress and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

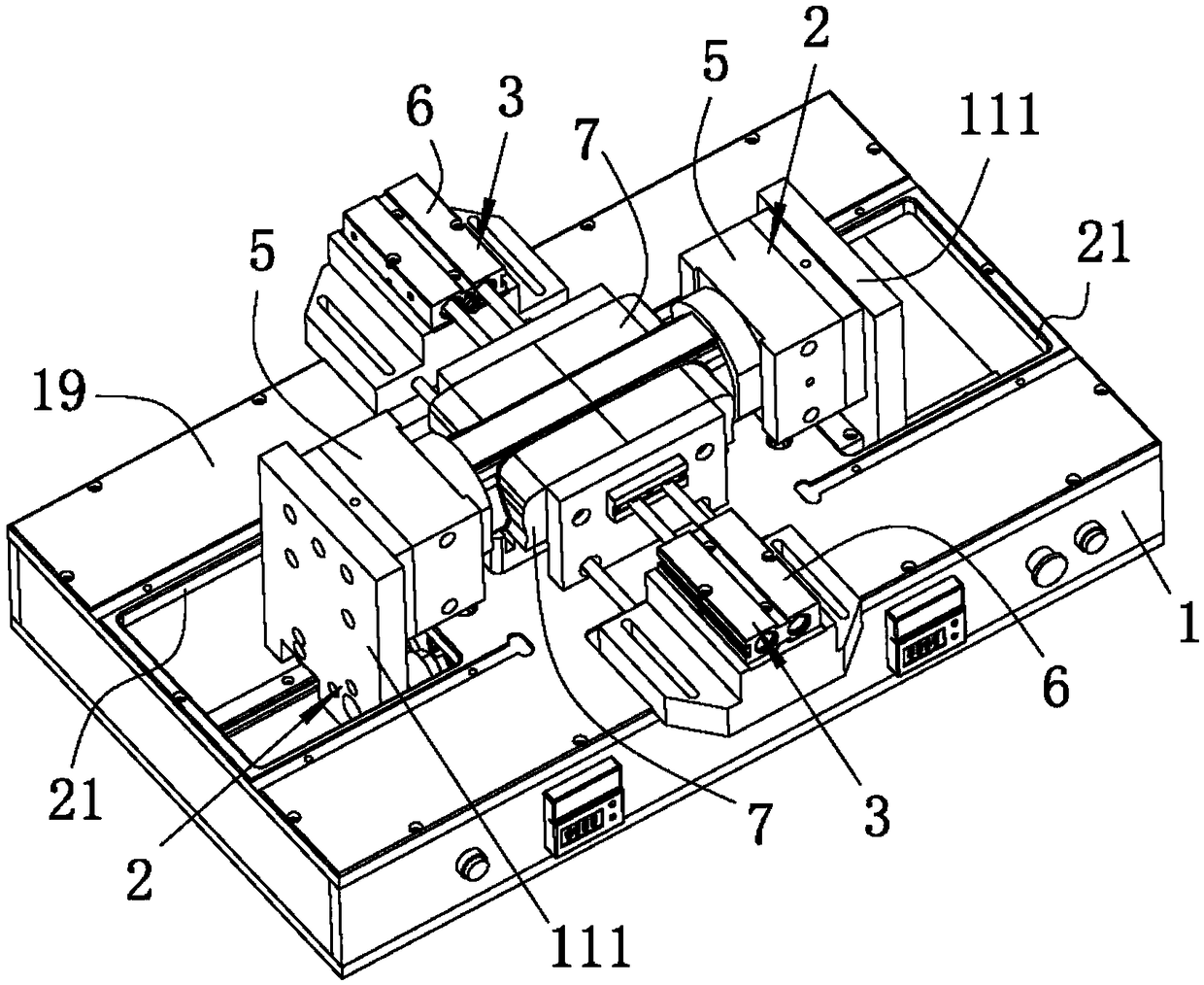

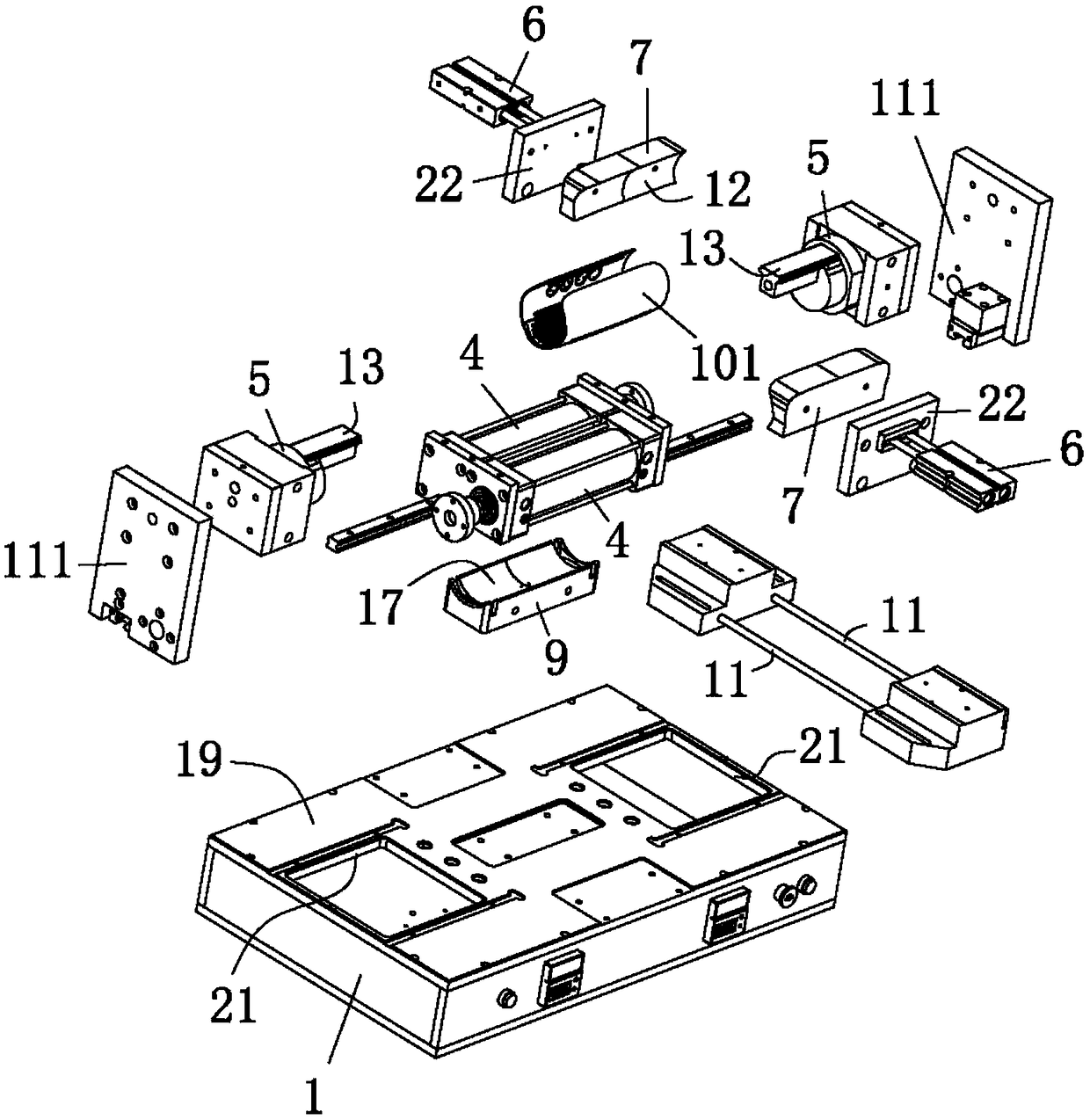

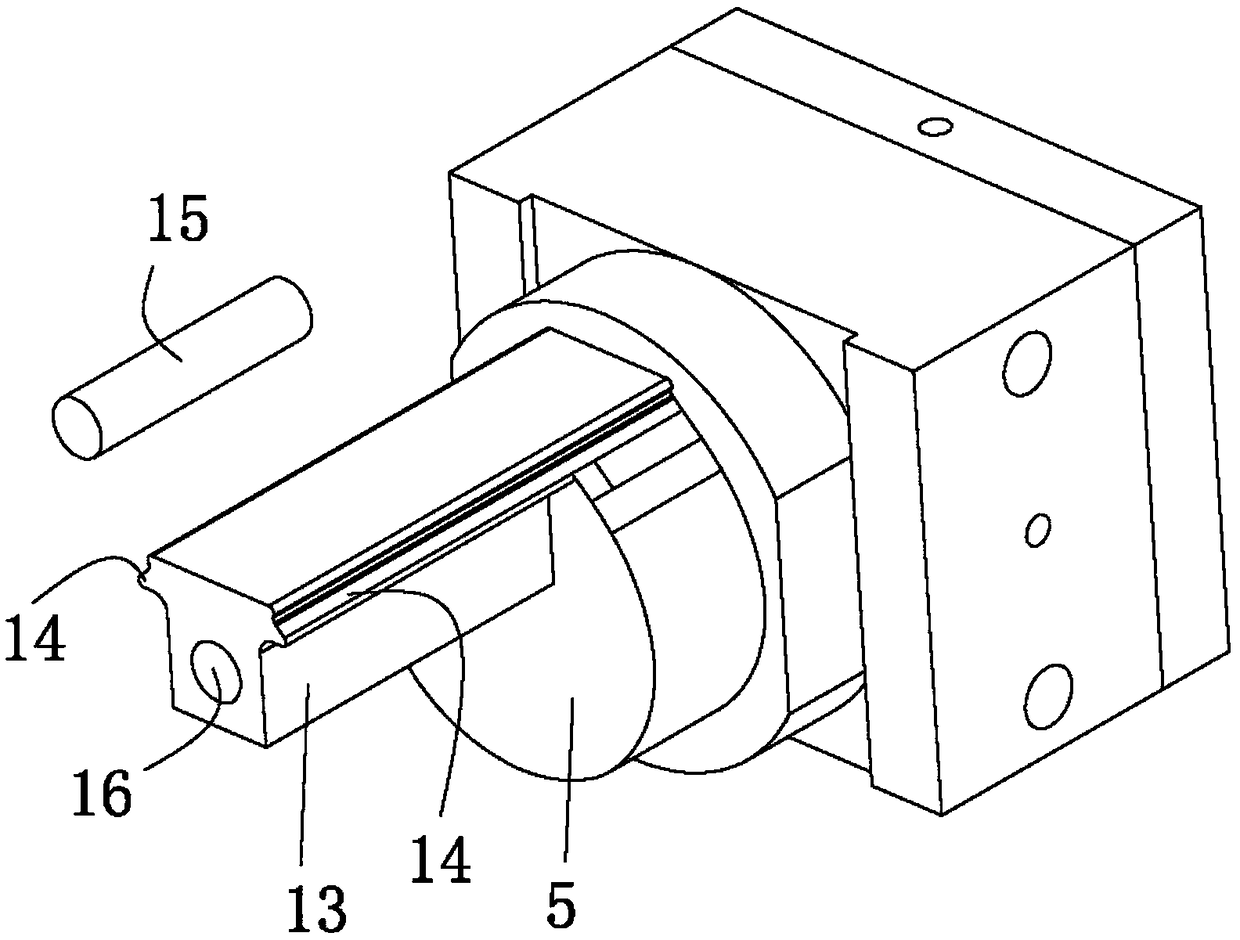

[0030] see Figure 1 to Figure 5 As shown, a heat press for audio case wrapping cloth of the present invention includes a frame body 1, a cork mechanism 2 and an extruding mechanism 3 arranged on the frame body 1, and the cork mechanism 2 includes a cork mechanism arranged on the frame body 1 The first driver 4, two corkscrews 5 that are movably arranged, the first driver 4 is used to drive the two corkscrews 5 to approach each other or move away from each other; The driving part 6, the two extruding plates 7 which are movable, the second driving part 6 is used to drive the two extruding plates 7 to approach each other or to move away from each other, and the cork mechanism 2 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com