Automatic drilling cutting discharging system and method

A technology of drilling cuttings and drainage pipes, applied in drainage, earthwork drilling, safety devices, etc., can solve the problems of affecting the drilling progress, high labor intensity, low work efficiency, etc., to speed up the drilling progress, eliminate potential safety hazards, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

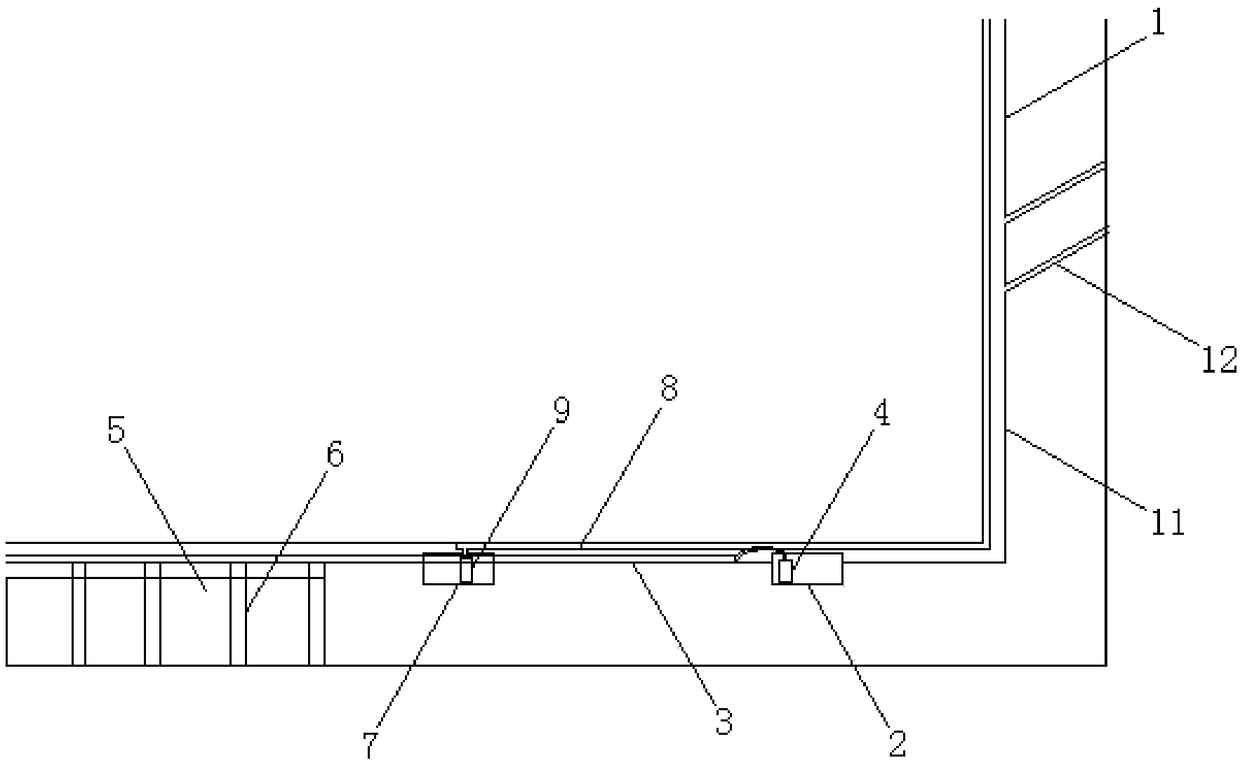

[0025] like figure 1 As shown, the automatic drill cuttings discharge system includes a drainage ditch 1, a first sedimentation tank 2, a first drainage pipe 3, a first submersible pump 4, a drill cuttings stack 5, a drill cuttings interception dam 6, a second sedimentation tank 7, The second drainage pipe 8, the second submersible pump 9.

[0026] Drainage ditch 1 comprises main drainage ditch 11, horizontal drainage ditch 12, and the length direction of main drainage ditch 11 is arranged along the roadway length direction where drilling site is located, and several horizontal drainage ditches 12 corresponding to each drilling site are respectively connected in each drilling site. Between the drilling site and the main drainage ditch 11 , the main drainage ditch 11 is connected between each horizontal drainage ditch 12 and the first sedimentation tank 2 .

[0027] The first sedimentation tank 2 is connected to the drilling cuttings concentration site through the first draina...

Embodiment 2

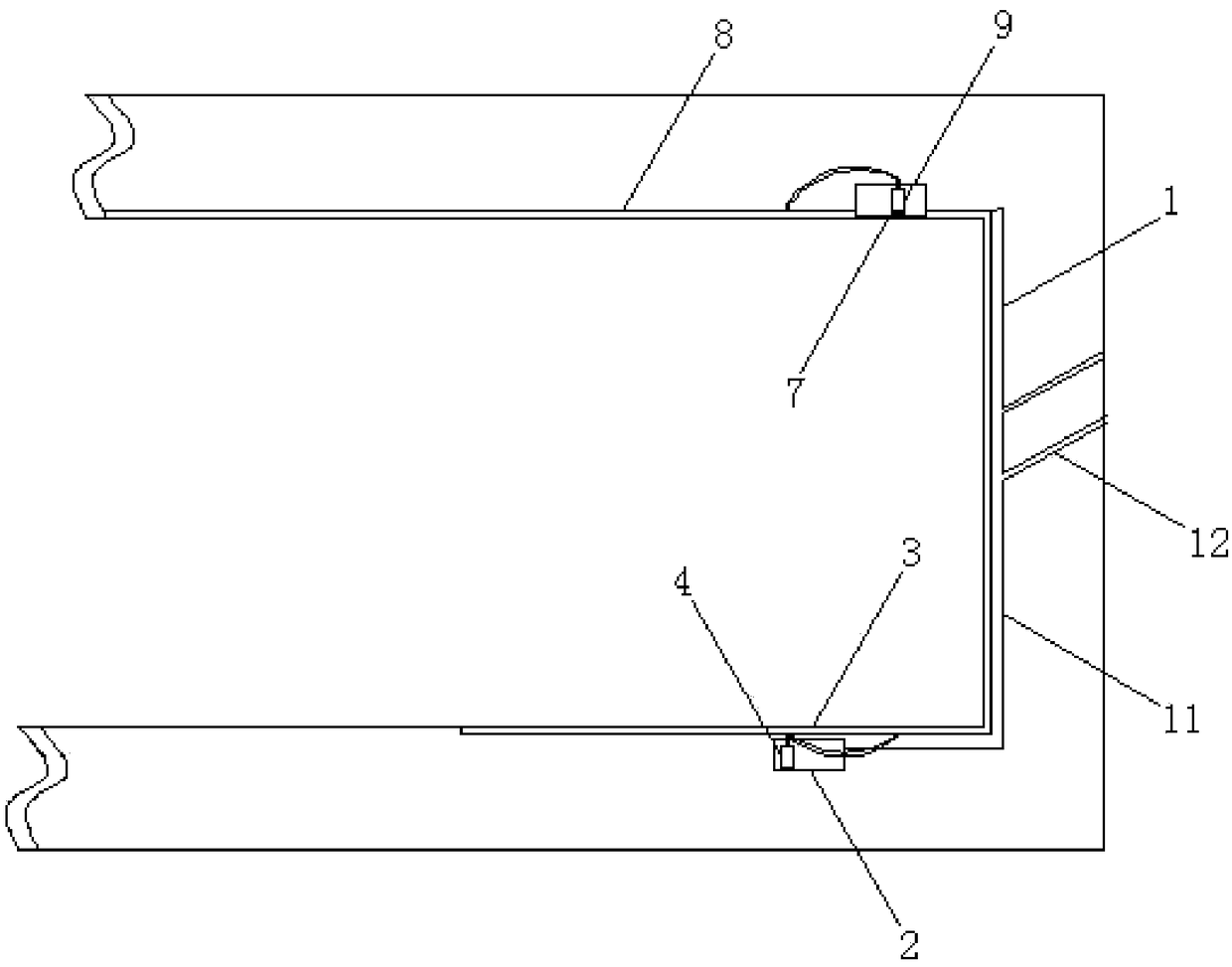

[0037] like figure 2 As shown, the automatic drill cuttings discharge system includes a drain 1 , a first sedimentation tank 2 , a first drainage pipe 3 , a first submersible pump 4 , a second sedimentation tank 7 , a second drainage pipe 8 , and a second submersible pump 9 .

[0038] Drainage ditch 1 comprises main drainage ditch 11, horizontal drainage ditch 12, and the length direction of main drainage ditch 11 is arranged along the roadway length direction where drilling site is located, and several horizontal drainage ditches 12 corresponding to each drilling site are respectively connected in each drilling site. Between the drilling site and the main drainage ditch 11 , the main drainage ditch 11 is connected between each horizontal drainage ditch 12 and the first sedimentation tank 2 .

[0039] The first sedimentation tank 2 is connected to the drilling cuttings concentration site through the first drainage pipe 3, the first submersible pump 4 is connected to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com