Aviation engine bearing nut locking structure

A technology for aero-engines and bearing nuts, applied to nuts, threaded fasteners, locking fasteners, etc., can solve the problems of poor assembly, high cost, and low reliability of anti-loosening structures, and improve the reliability of imitation loosening , Excellent assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

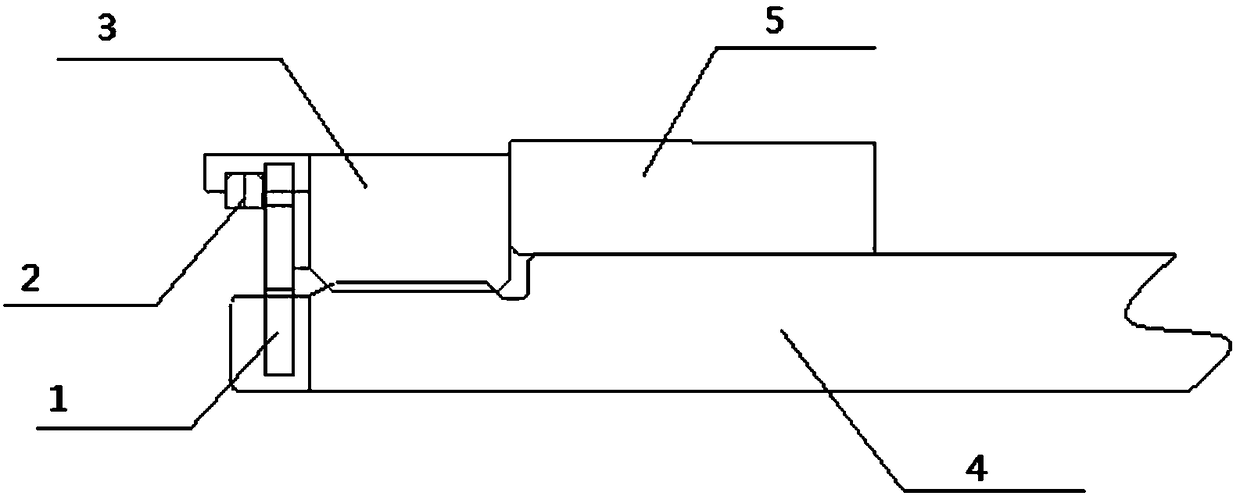

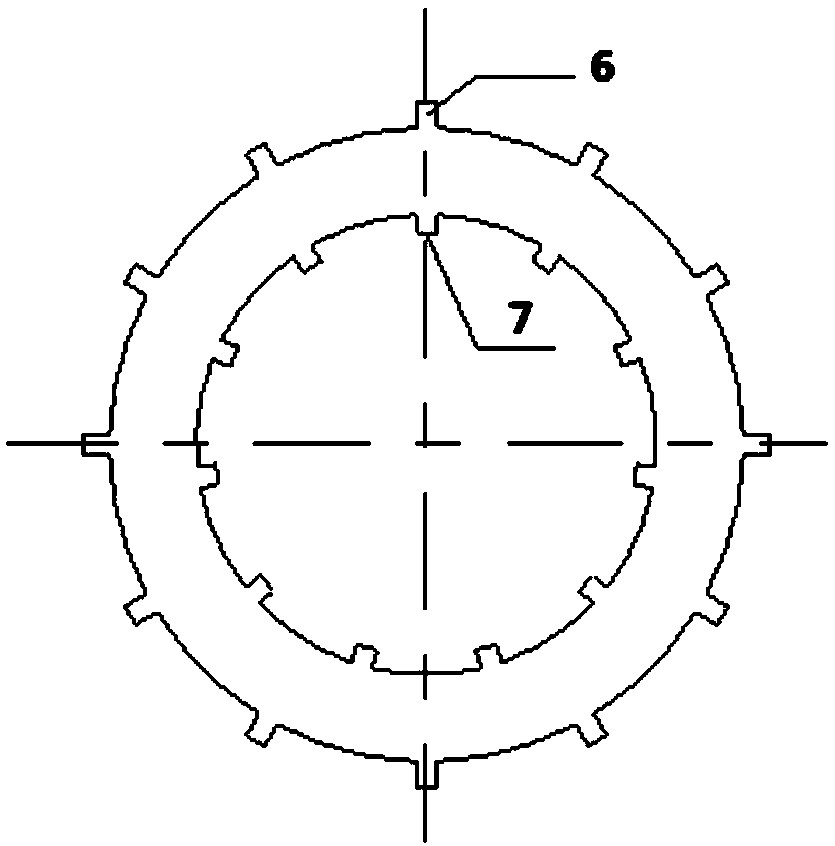

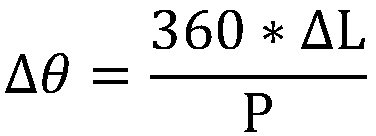

[0022] The design concept of the technical solution of the present invention is: one end of the bearing nut 3 is pressed against the inner ring 5 of the bearing, a number of grooves are opened on the other end of the bearing nut 3 and the journal 4, and a lock plate 1 with multiple teeth inside and outside is designed, and multiple teeth are assembled in the groove. Tooth lock piece 1, the outer teeth 6 and inner teeth 7 of the lock piece 1 prevent the bearing nut 3 from loosening, and the retaining ring 2 is used to fix the lock piece to prevent the lock piece 1 from withdrawing axially. The locking piece is formed to prevent the nut from loosening, and the retaining ring axially fixes the structure of the locking piece. During the working process, the multi-tooth structure of the locking piece constrains each other, and will not vibrate un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com