Venturi nozzle air flow calibration method for overall test of aero-engine

A Venturi nozzle and aero-engine technology, used in engine testing, jet engine testing, gas turbine engine testing, etc., can solve the problem of high requirements for accurate measurement of air flow, and meet calibration requirements, strong applicability, and high calibration accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

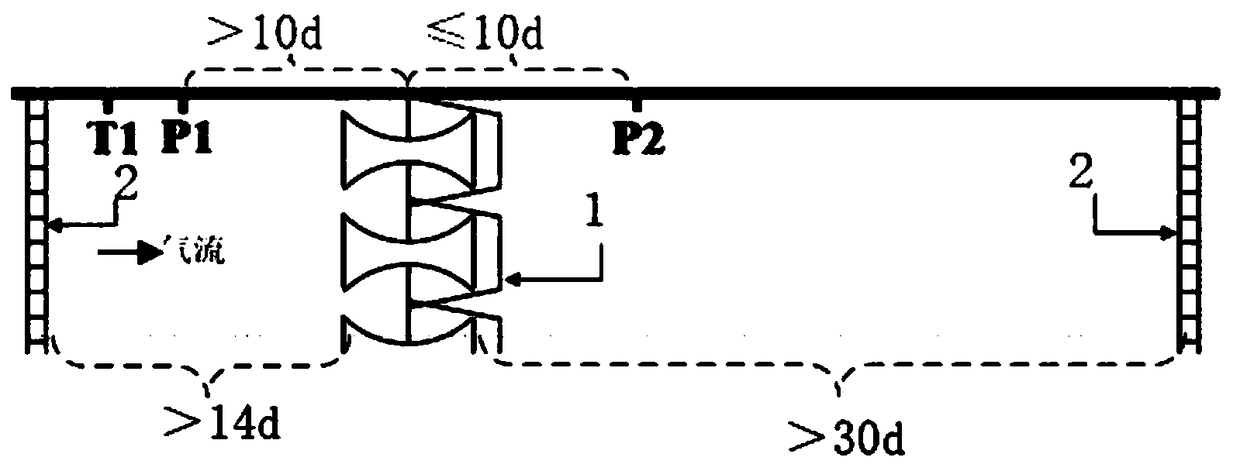

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Because the large bypass is larger than the general structural size of the turbofan engine, during the high-altitude bench test, the air flow measurement process pipeline is connected to the engine inlet, and the structural size is also larger. For the calibration of the air flow measurement process duct of the engine inlet of the high-altitude platform that is larger than 1 meter, or even close to 3 meters, there is no laboratory condition for independent calibration at home and abroad. For this reason, the present invention aims to rely on the high-altitude test capability, and for the first time proposes the scheme of on-site calibration on the high-altitude platform, and can realize the air flow calibration of the altitude velocity characteristic within the full envelope of the engine. calibration within the range.

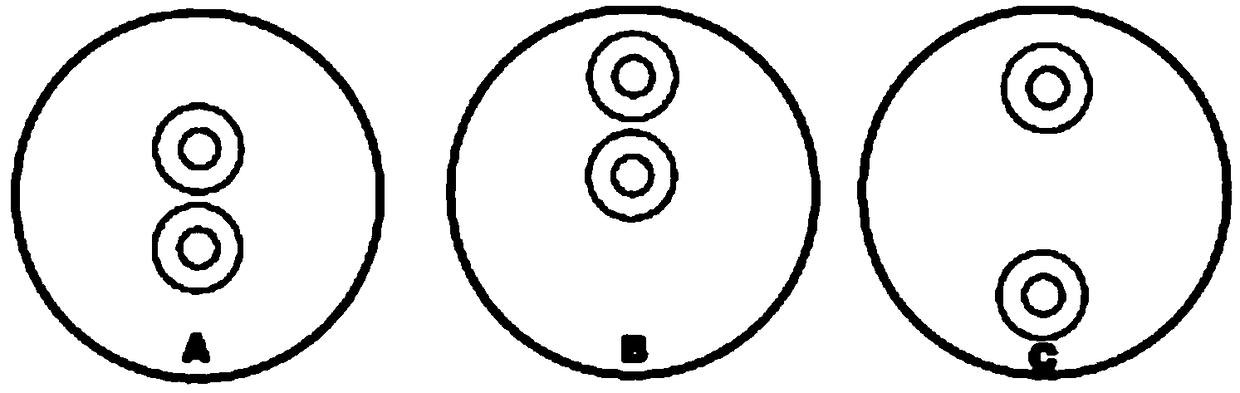

[0017] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com