A security risk analysis method and system for collaborative work

A safety risk and risk technology, applied in the information field, can solve problems such as dangerous points and difficult positions of operators, complex on-site environment, and complex manual safety monitoring methods, so as to improve risk awareness and enhance the level of protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] Through the combination of precise positioning technology and intelligent electric power operation technology, the present invention prompts potential safety hazards and prevents accidents such as falling from high altitude, mistakenly touching electrified bodies and misoperating equipment caused by fatigue work, habitual violations and coordination mechanism disorder, etc. Improve the level of safety protection on the job site.

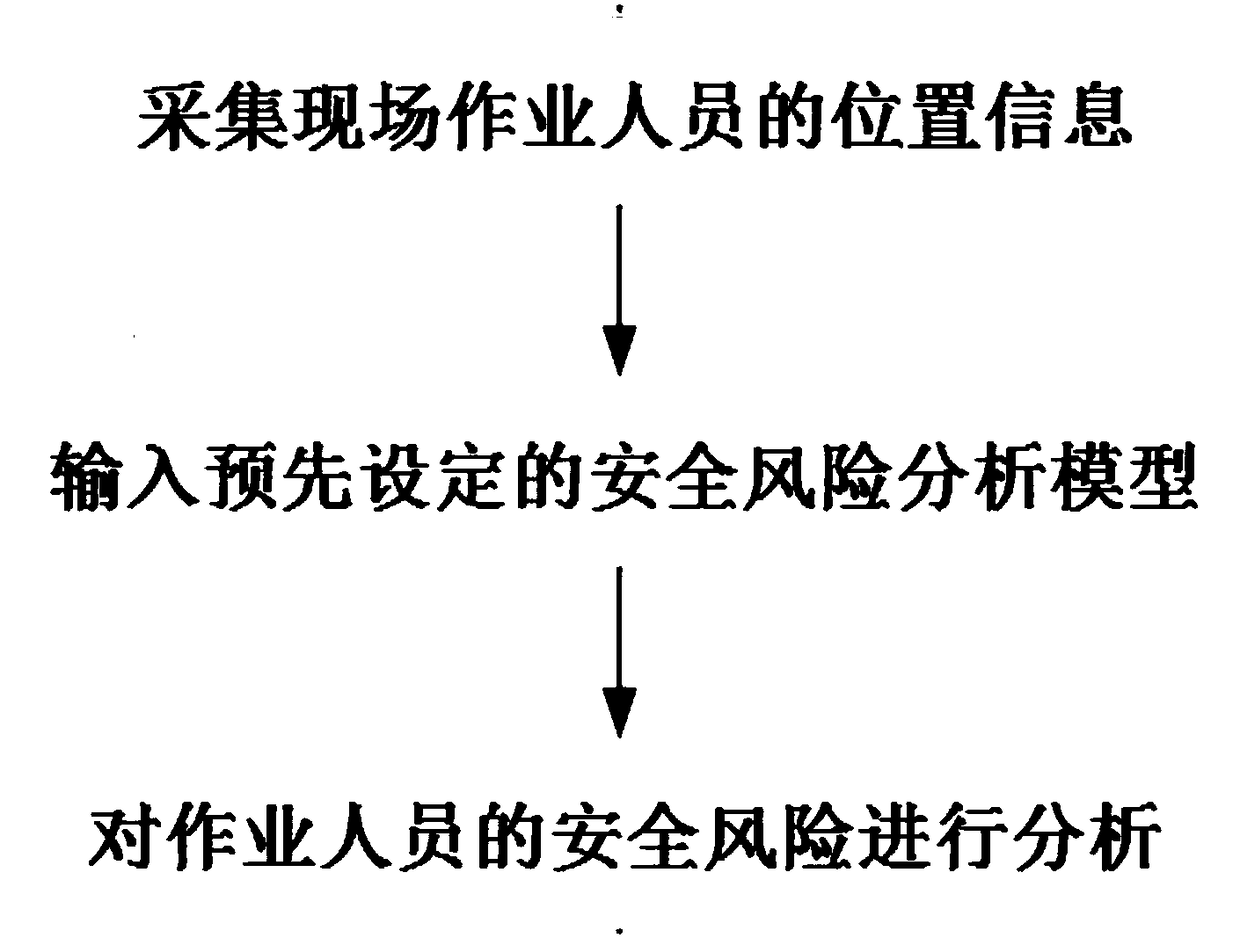

[0030] Such as figure 1 As shown, first, the precise location information of on-site workers is obtained from wearable devices such as smart helmets or smart bracelets worn by on-site workers, and input into the safety risk analysis model.

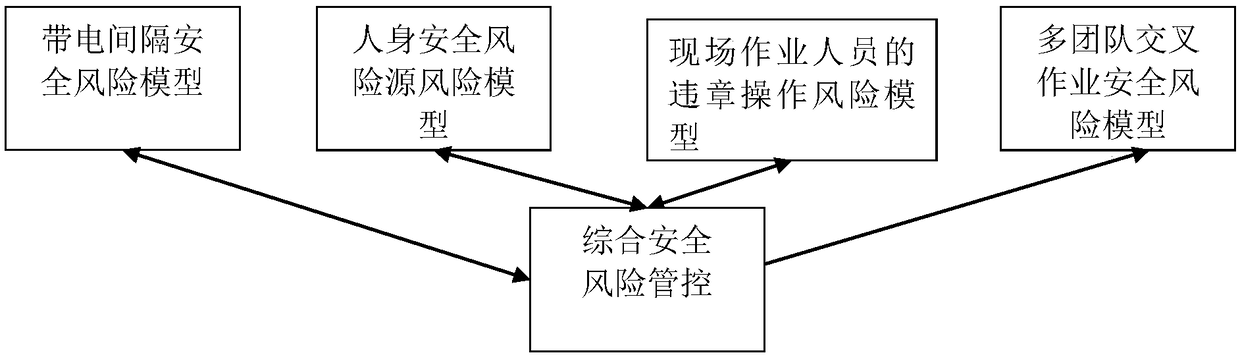

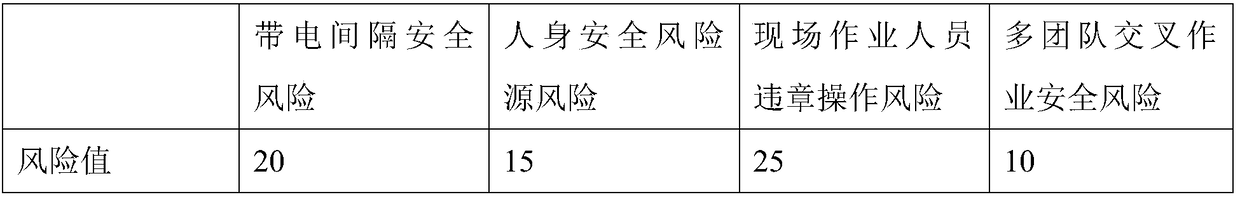

[0031] The safety risk analysis model includes: live interval safety risk model, personal safety risk source risk model, on-site operator violation operation risk model and multi-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com