Butt joint welding process of device opening with nickel-based isolation layer and heat-resistant steel pipeline

A technology of welding process and isolation layer, which is applied in the field of butt welding process between equipment port with nickel-based isolation layer and heat-resistant steel pipe, which can solve the problems of side bending fracture and low yield of welded parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

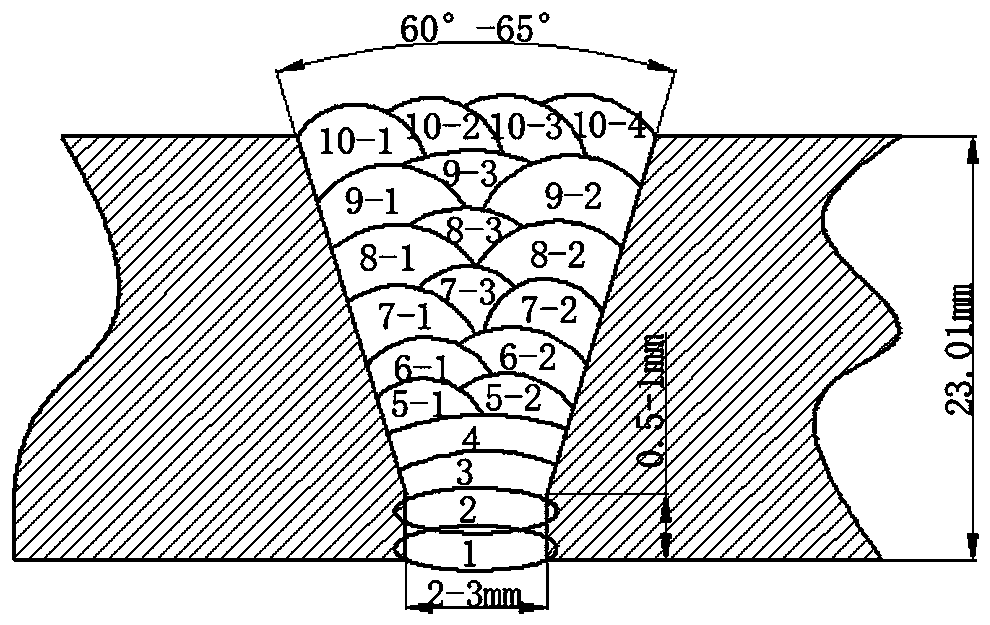

[0023] A butt welding process between the equipment port with a nickel-based isolation layer and a heat-resistant steel pipe. The nickel-based welding material is used for welding, and then heat treatment is performed after welding; the temperature of the heat treatment is 700~750°C, and the time is more than 2 hours. The time is calculated based on the wall thickness of the material. The calculation standard is 2.4 minutes per millimeter of thickness, and the calculated minimum heat preservation is not less than 2 hours.

[0024] The specific situation for welding nickel-based welding consumables is as follows:

[0025] Grind off the isolation layer of the equipment port to make both ends of the chrome-molybdenum steel and then weld.

[0026] The second specific situation for welding nickel-based welding consumables is:

[0027] Surfacing nickel-based welding consumables for heat-resistant steel pipes. After heat treatment, there are nickel-based welding consumable isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com