Roller and machining technology thereof

A processing technology and roller technology, which is applied in the direction of rotary printing machine, printing, printing machine, etc., can solve the problem of high stress at the connection between the main shaft and the side plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

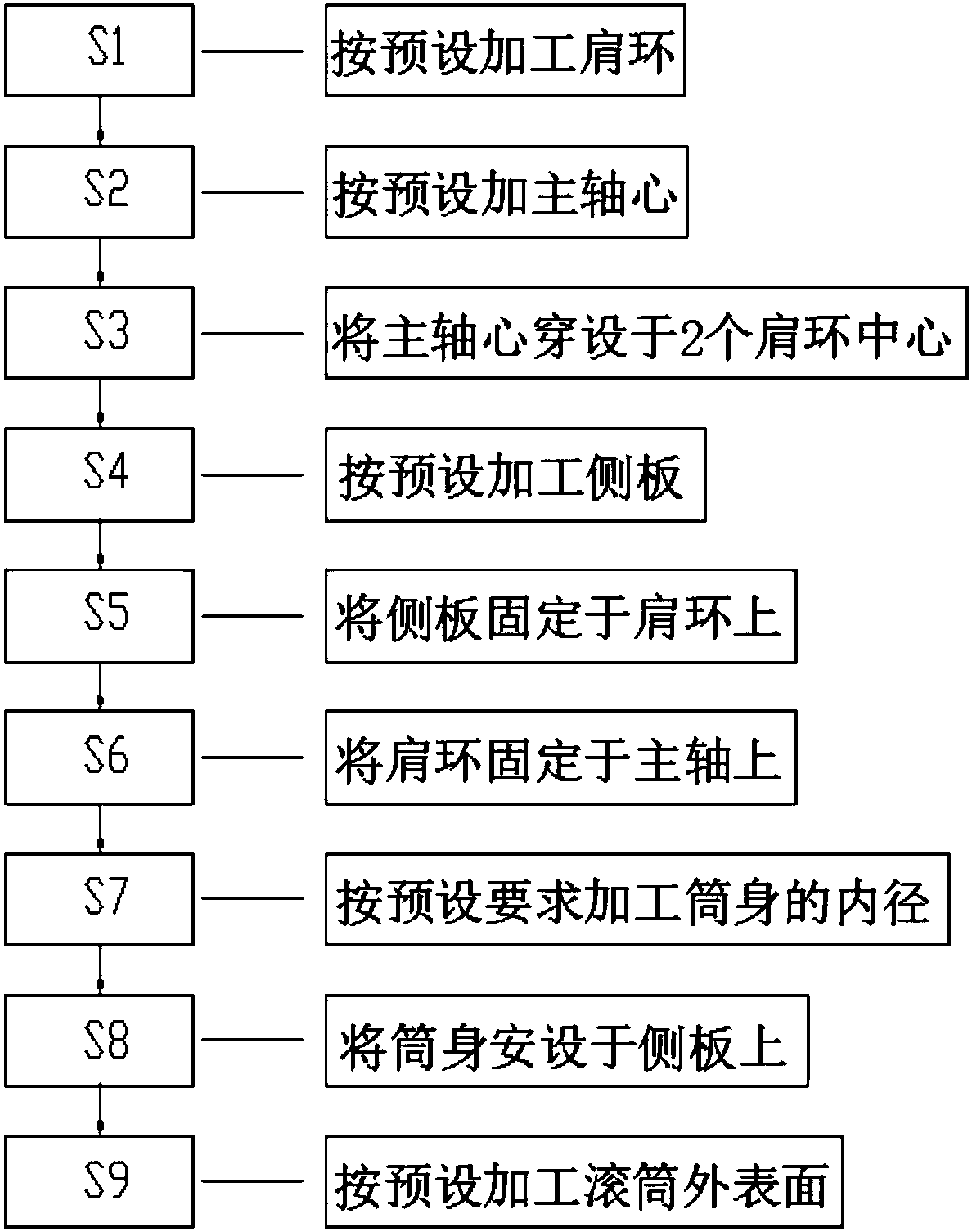

[0022] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

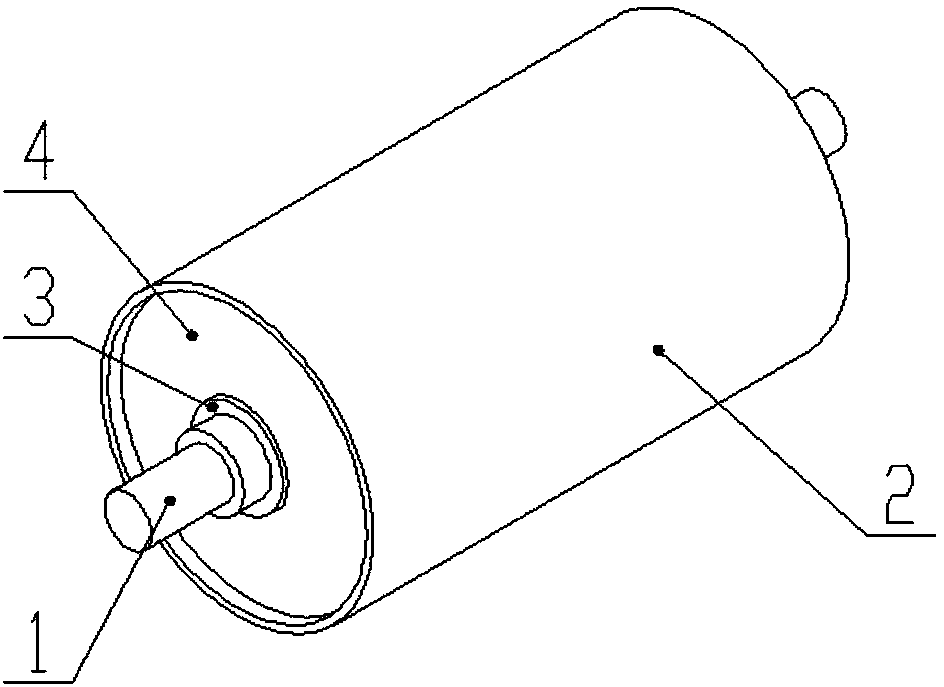

[0023] Such as figure 1 As shown, the roller provided by this application mainly solves the problem of excessive stress at the connection between the main shaft and the side plate, is suitable for the processing of rollers with high-precision requirements, can improve the quality and accuracy of roller processing, and has processing The advantage of simple process.

[0024] The above-mentioned drum includes a barrel 02, a side plate 04 arranged on the side plate shoulder ring 03, and a main shaft 01 passing through the two shoulder rings; the barrel 02 is supported by two side plates 04 inside.

[0025] The side plate shoulder ring is inserted through the middle of the side plate 04, and is fixed by welding after positioning;

[0026] The mating part of the main shaft 01 and the two side plate shoulder rings is a conical type fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com