Mechanical arm type cement product 3D printing machine

A technology for 3D printers and cement products, which is applied in the field of cement product printing, can solve the problems of restricting the printing efficiency of 3D printers for cement products, easy blockage of nozzles, inconvenient use, etc., and achieve the effect of highlighting substantive features, avoiding searching, and increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

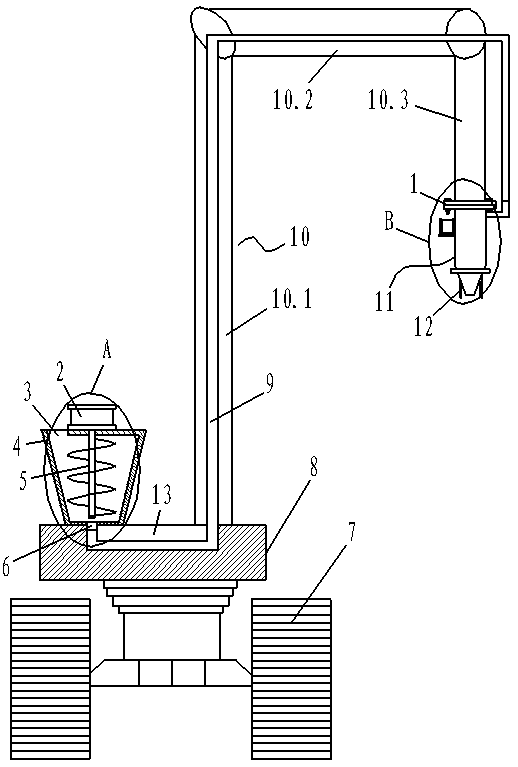

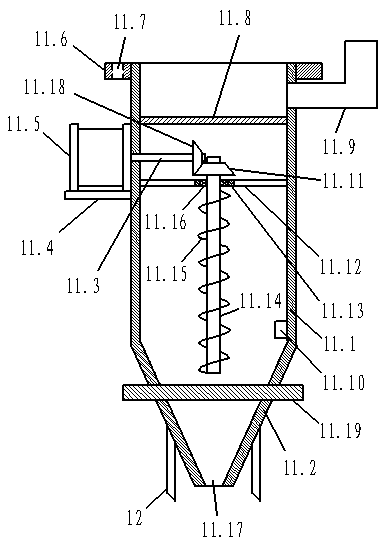

[0042] In order to make the technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be described clearly and completely in conjunction with the accompanying drawings.

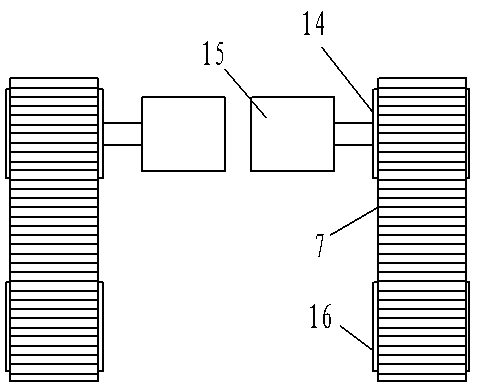

[0043] Figure 1-5 It is a specific implementation of the robot arm type cement product 3D printer of the present invention. In this embodiment, the mechanical arm type cement product 3D printer includes a printing nozzle 11, a support base 8 with a walking mechanism, a six-degree-of-freedom mechanical arm 10 fixedly mounted on the support base 8, and a support base The cement storage box 4 on the 8 and the cement conveying mechanism for conveying the cement in the cement storage box 4 to the printing nozzle 11; the printing nozzle 11 is fixed at the end of the six-degree-of-freedom mechanical arm 10; the six-degree-of-freedom machine The end of the arm 10 is located on the side of the support base 8 and can move in a vertical plane perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com