A fully automatic bucket elevator for material conveying

A fully automatic, bucket elevator technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as waste of labor, troublesome operation, etc., to achieve the effect of promoting smooth sliding, easy implementation, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

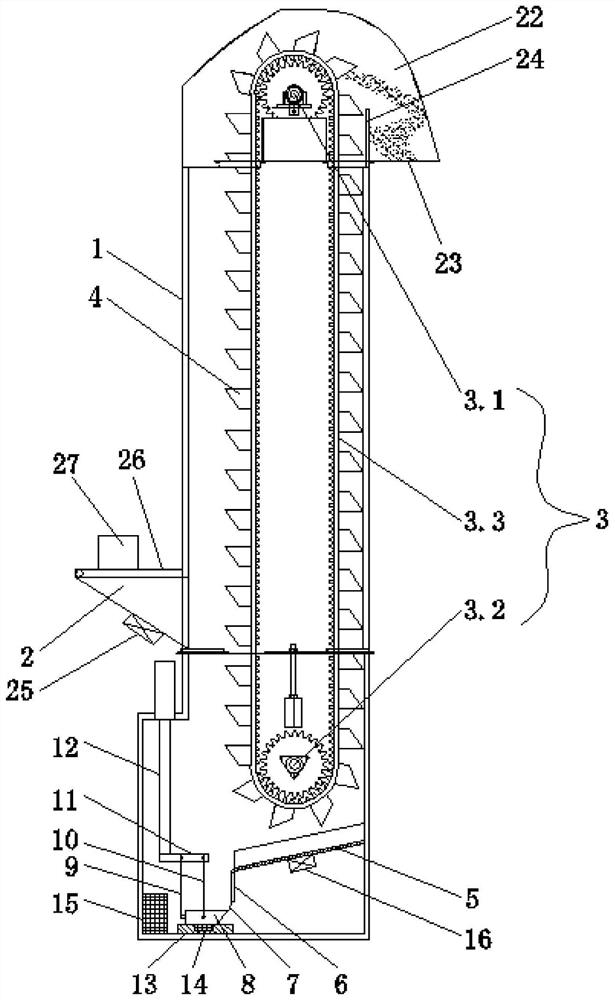

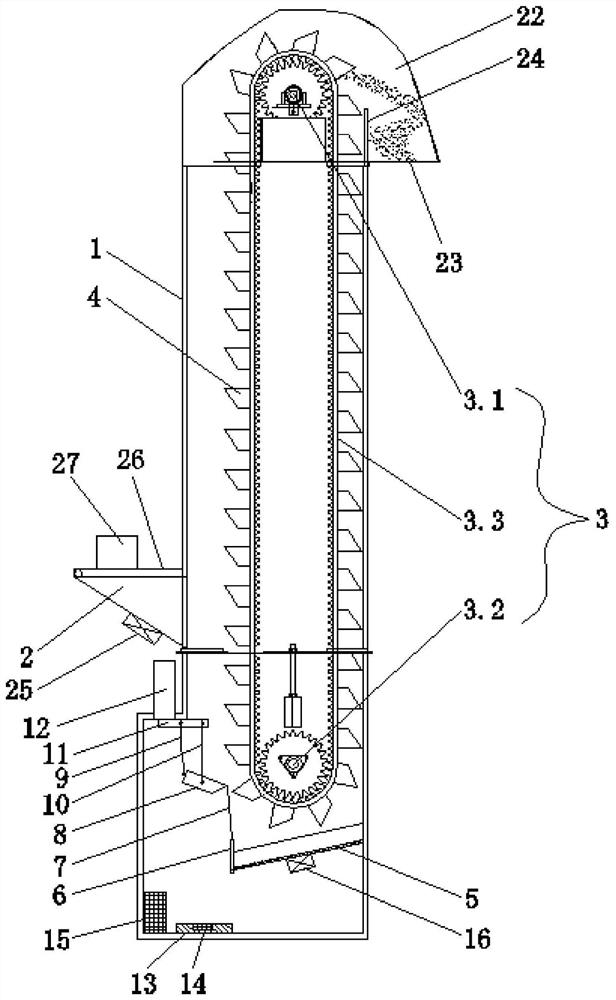

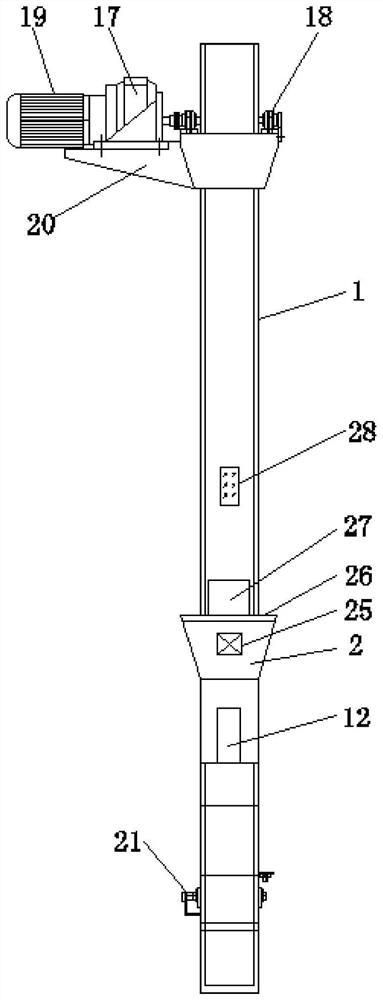

[0033] Such as Figures 1 to 3 As shown, the present embodiment provides a fully automatic bucket elevator for material transportation, including a casing 1, a feed hopper 2 is provided at the side end of the casing 1, and a bucket 2 is provided in the casing 1 for moving materials from a low place to a high place. The chain conveying mechanism 3 for transportation, the outer edge of the chain conveying mechanism 3 is provided with several transport hoppers 4, the housing 1 is provided with a collecting tank 5 located below the chain conveying mechanism 3, and the collecting groove 5 faces the direction of the feeding hopper 2 Inclined downward, one end of the collecting tank 5 inclined downward is hinged with a blocking plate 6, the blocking plate 6 is connected with an elastic stay cord 7, and the other end of the elastic stay cord 7 is connected with a collection box 8 located directly below the outlet of the collecting tank 5 , the other side end of the collection box 8 is c...

Embodiment 2

[0036] Such as Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a base 13 is provided at the inner bottom of the casing 1, the collection box 8 is located on the base 13, and the collection box 8 is located on the base 13. 8 The weight sensor 14 at the bottom, the central processor 15 is arranged in the casing 1, and the central processor 15 is electrically connected with the weight sensor 14 and the telescopic cylinder 12 at the same time.

[0037] In this embodiment, when the material in the collecting box reaches a certain weight, the weight sensor sends a signal to the central processor, and the central processor processes the signal and then sends an instruction to the telescopic cylinder, and the telescopic cylinder begins to complete a "shrink-extend" "Long" working stroke, so as to complete the process of conveying the spilled materials, with a high degree of intelligence and easy implementation.

Embodiment 3

[0039] Such as figure 1 with 4 As shown, this embodiment is further optimized on the basis of embodiment 1. Specifically, the vertical section of the collection tank 5 is U-shaped, and the bottom of the collection tank 5 is provided with a first vibrator 16 .

[0040] In this embodiment, the U-shaped collecting trough is beneficial to gather the materials at the bottom of the collecting trough, which is convenient for guiding the materials. The first vibrator generates a sense of vibration to the collecting trough, so that the materials can slide smoothly into the collecting box below, avoiding Material is clogged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com