A kind of preparation method of nitrile rubber with dynamic crosslinking structure

A nitrile rubber, dynamic cross-linking technology, applied in the field of self-healing and reprocessable rubber, to achieve good dynamic reversibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

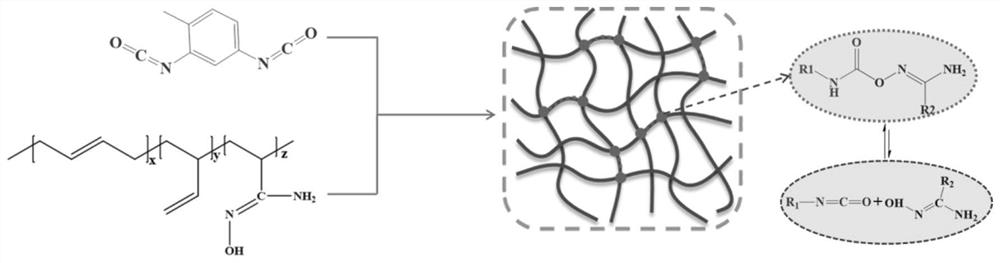

Method used

Image

Examples

Embodiment 1

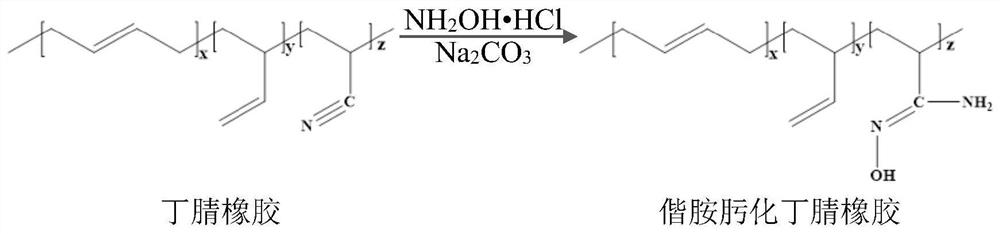

[0030] Step 1. Cyanooximation: Dissolve 28.08g (0.177mol) of NBR3305E in 250mL of dichloromethane in a 500mL three-neck flask, mechanically stir at 40°C and reflux to dissolve; pour into 50mL of absolute ethanol after 5 minutes Add 14g (1.23eq) of hydroxylamine hydrochloride and dissolve for 15 minutes; finally, weigh 40g (2.13eq) of sodium carbonate into a three-necked flask, mechanically stir and reflux at 40°C overnight (about 16h).

[0031] (Based on the calculation of cyano group content in nitrile rubber, 1mol cyano group corresponds to 158.5g NBR3305E.)

Embodiment 2

[0032] Example 2: Dissolve 28.08g (0.177mol) of NBR3305E in 250mL of dichloromethane in a 500mL three-necked flask, mechanically stir at 40°C and reflux to dissolve; pour 50mL of ethylene glycol into the solution, and add 14g (1.23 eq) Hydroxylamine hydrochloride was dissolved for 15 minutes; finally, 40 g (2.13 eq) of sodium carbonate was weighed and added into a three-necked flask, and mechanically stirred at 40° C. and condensed and refluxed overnight for reaction (about 16 hours).

Embodiment 3

[0033] Example 3: In a 500mL three-necked flask, 28.08g (0.177mol) of NBR3305E was dissolved in 250mL of dichloromethane, mechanically stirred at 40°C and refluxed to dissolve; at the same time, 14g (1.23eq) of hydroxylamine hydrochloride and 40g (2.13 eq) Sodium carbonate was mixed and added into a beaker filled with 50 mL of ethanol, and stirred by magnetic force for 15-30 min. Subsequently, the latter was added to the dissolved nitrile rubber, and the reaction was carried out overnight at 40°C with mechanical stirring and condensing and reflux (about 16 hours).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com