Supporting positioning formwork device for construction of beam column joint of prefabricated building and application thereof

A technology of support positioning and beam-column joints, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of occupying the lower space, difficult to correct, and artificial errors in the final stage of the shaped steel mold, so as to reduce the occupied space , Solve the error problem and avoid the effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

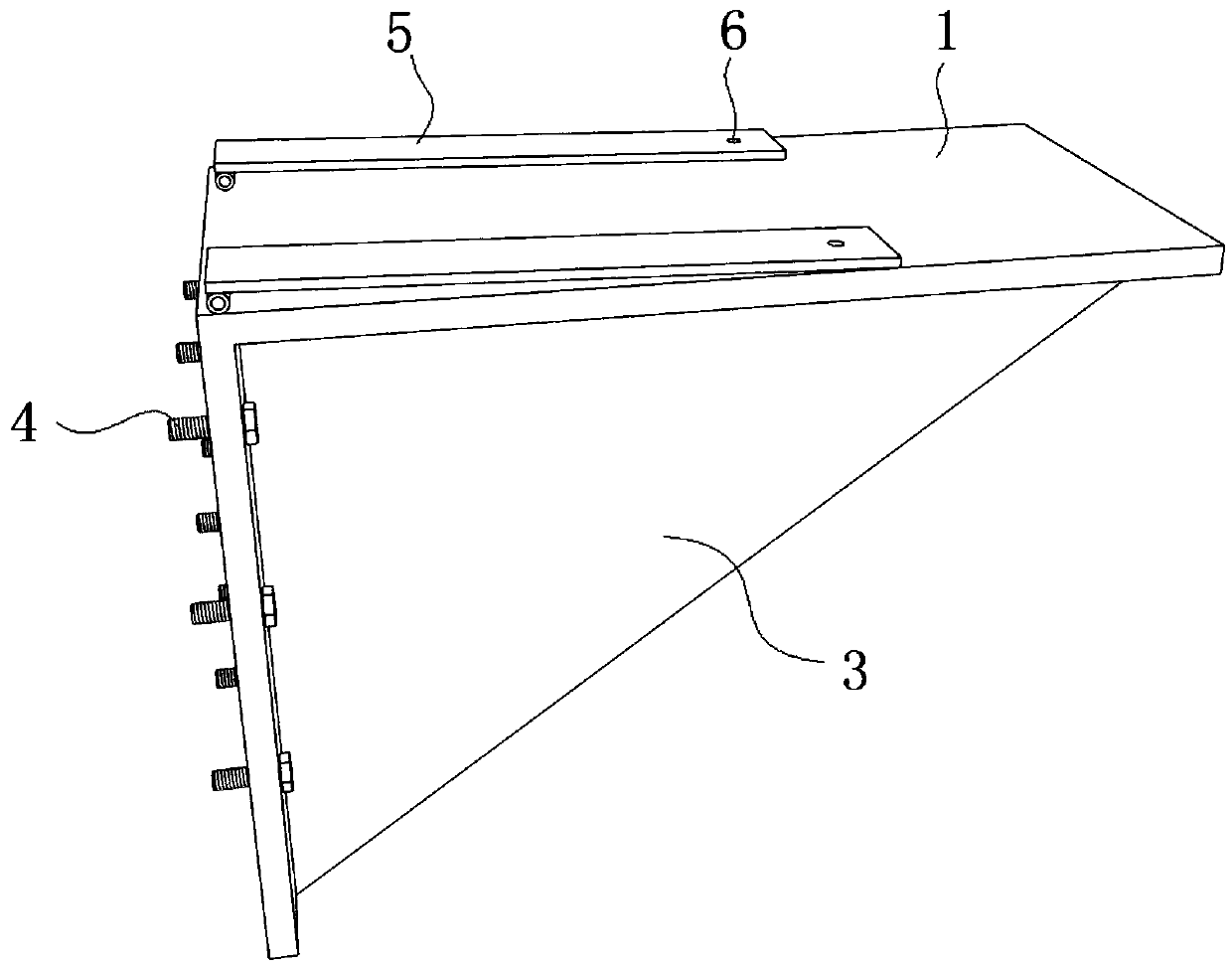

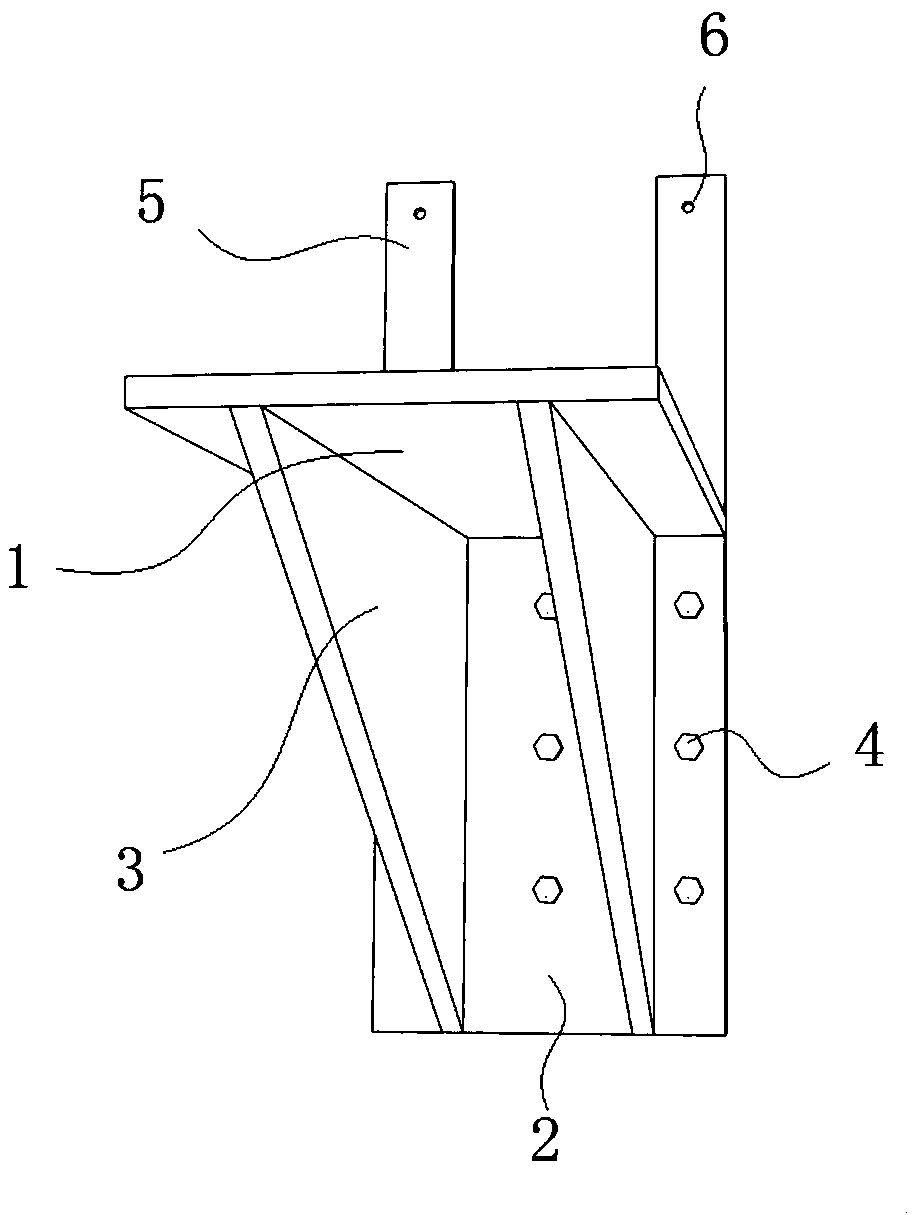

[0028] Embodiment 1: as Figure 1 to Figure 7As shown, the number of fixing bolts 4 of the device and the number of bolt holes reserved for prefabricated columns 10 are determined according to the actual situation of the site. The template device is installed and fastened with fixing bolts 4 according to the reserved bolt holes. The supporting and positioning formwork device for the construction of beam-column joints in prefabricated buildings is characterized in that it includes: a supporting body in the shape of a right-angled steel. The supporting body includes a horizontal structural surface 1, which is vertical to the horizontal structural surface 1 and connected by a corner surface 2, at least two triangular support surfaces 3 connected between the horizontal structural surface 1 and the vertical mounting surface 2, and several outwardly extending fixing bolts 4 are installed on the vertical mounting surface 2, and the horizontal structural surface 1 is connected with T...

Embodiment 2

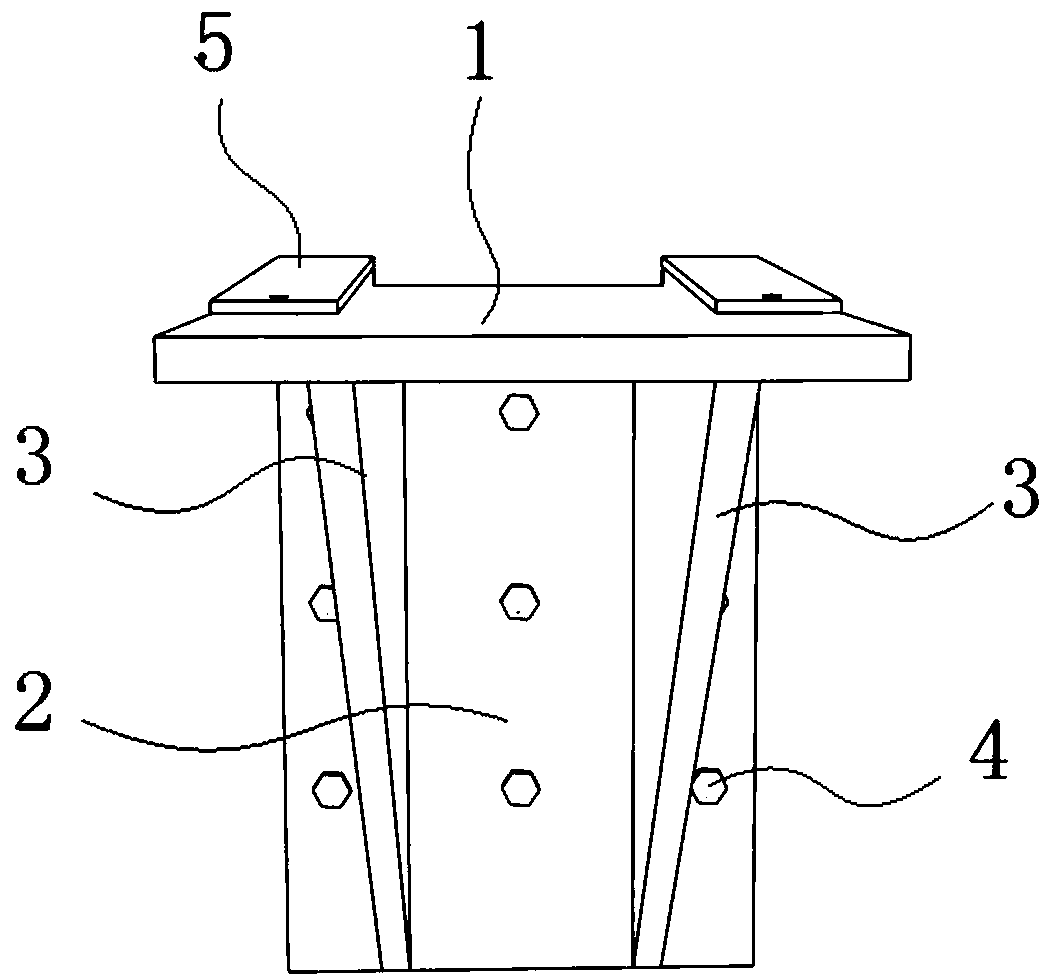

[0031] Embodiment 2: as Figure 8-10 As shown, a combined use example of a supporting and positioning formwork device is used. When hoisting the prefabricated beam column 11, the turning and positioning steel plate 5 is rotated to contact the structural surface by using the horizontal rotation shaft 7. The distance between the two turning and positioning steel plates 5 is exactly the same as the The width of the column 11 and the accurate positioning of the installation of the prefabricated beam and column 11. After the installation of the prefabricated beam and column 11, the position of the prefabricated beam and column 11 can be accurately stuck due to the existence of the overturned positioning steel plate 5, and the position of the prefabricated beam and column 11 will not be shifted, including the combination of four support and positioning formwork devices In use, the respective vertical mounting surfaces 2 of the four supporting and positioning formwork devices are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com